Topic: E3D All-Metal Hotends - US Distributor

Hi there!

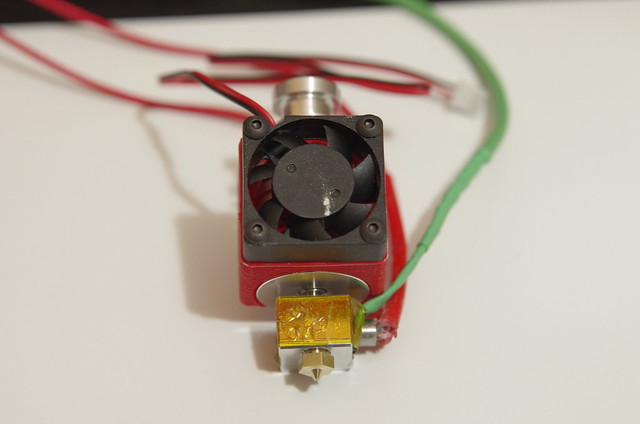

AccelerationLabs (the company I started to produce the Filastruder) has become a distributor of the acclaimed E3D hotend:

(photos courtesy of adrian)

This hotend is pretty well known here on the forums - here's one of the early threads on retrofitting one:

http://www.soliforum.com/topic/2584/got … nted-pics/

I've been really impressed so far, but don't take my word for it - here's a print with an E3D using PLA filament made on a Filastruder:

and one with ABS from a Filastruder:

Anyway, I talked to Sanjay (what a great guy!) and got things squared away. Here's the link to the store:

http://www.filastruder.com/products/all … e3d-hotend

Both prints were done by 2n2r5 here on the forum.

The first 20 orders can use the coupon code "FreeShipE3D" for free shipping within the US. That brings the total cost to $69.99 shipped, when ordering from across the pond will run you $86.94 - assuming the currency conversion doesn't change much.