Topic: Got my new E3D All-Metal Hotend V4 - (Updated with Mounted Pics)

Got my E3D All Metal Hotend today.

Its a DIY kit, so some assembly is required. I've taken pics during the build and tomorrow I'll do a full write up.

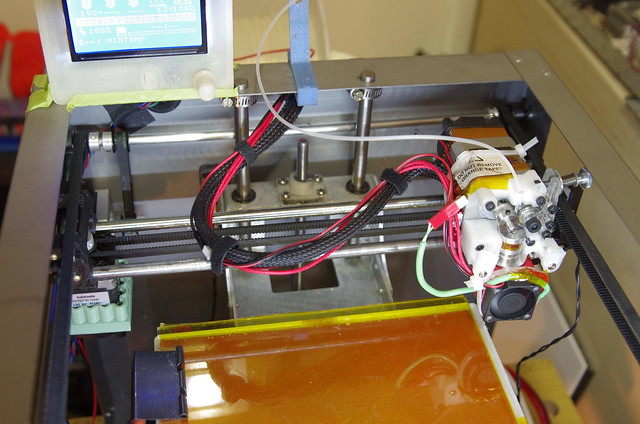

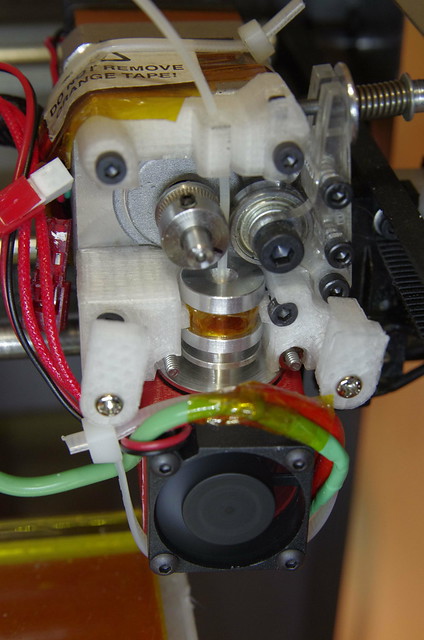

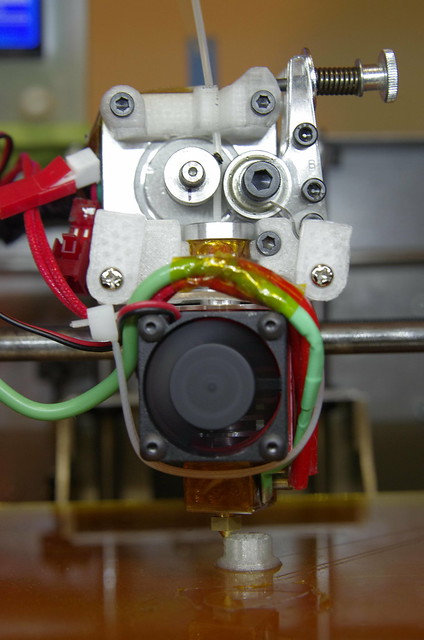

Good news is, it does fit lawsy's Mk4 ... but you will need to change the bolt arrangement as its too wide at the extruder carriage bolt setup. More info on that tomorrow, but in the meantime, heres a couple of sneak peek pics:

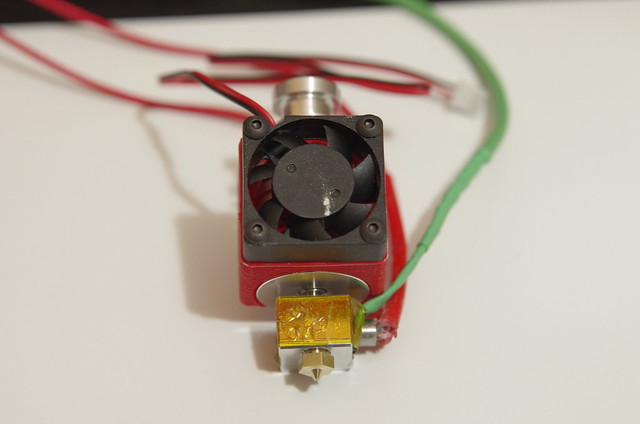

Heres whats in the kit you get:

Assembled (albeit I've had a problem in that the heater cartridge wont go all the way in - or come out - but its close enough..)

And try doing this with a PEEK nozzle ![]()

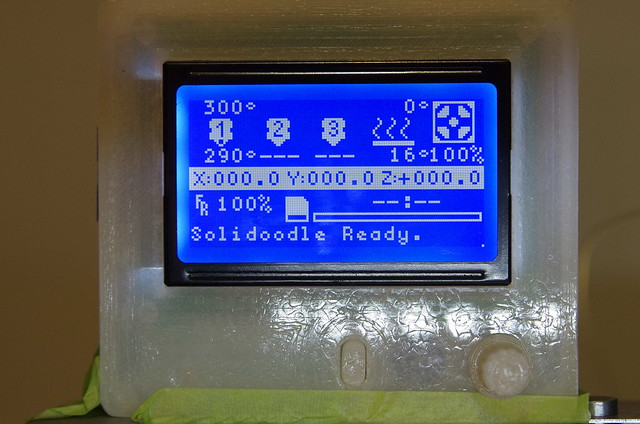

And yes, you can hold the filament end of the hot-end in your fingers with the nozzle at 300° ![]()

![]()