Re: Filament Extruder - Convert pellets to filament

The standard SD "jigsaw puzzle" actually works great. It's flaws are mostly regarding ease of use maintenance of the hot end is required.

You are not logged in. Please login or register.

SoliForum - 3D Printing Community → Filastruder → Filament Extruder - Convert pellets to filament

The standard SD "jigsaw puzzle" actually works great. It's flaws are mostly regarding ease of use maintenance of the hot end is required.

Thanks for the input everyone. What extruders are you all using without flaw or modification? Is SD working without a hitch?

SD works well in my experience with Lawsy's MK4 replacement. The stock acrylic jigsaw is really brittle and prone to cracking. I have only ever owned Solidoodles, so I can't comment on other designs.

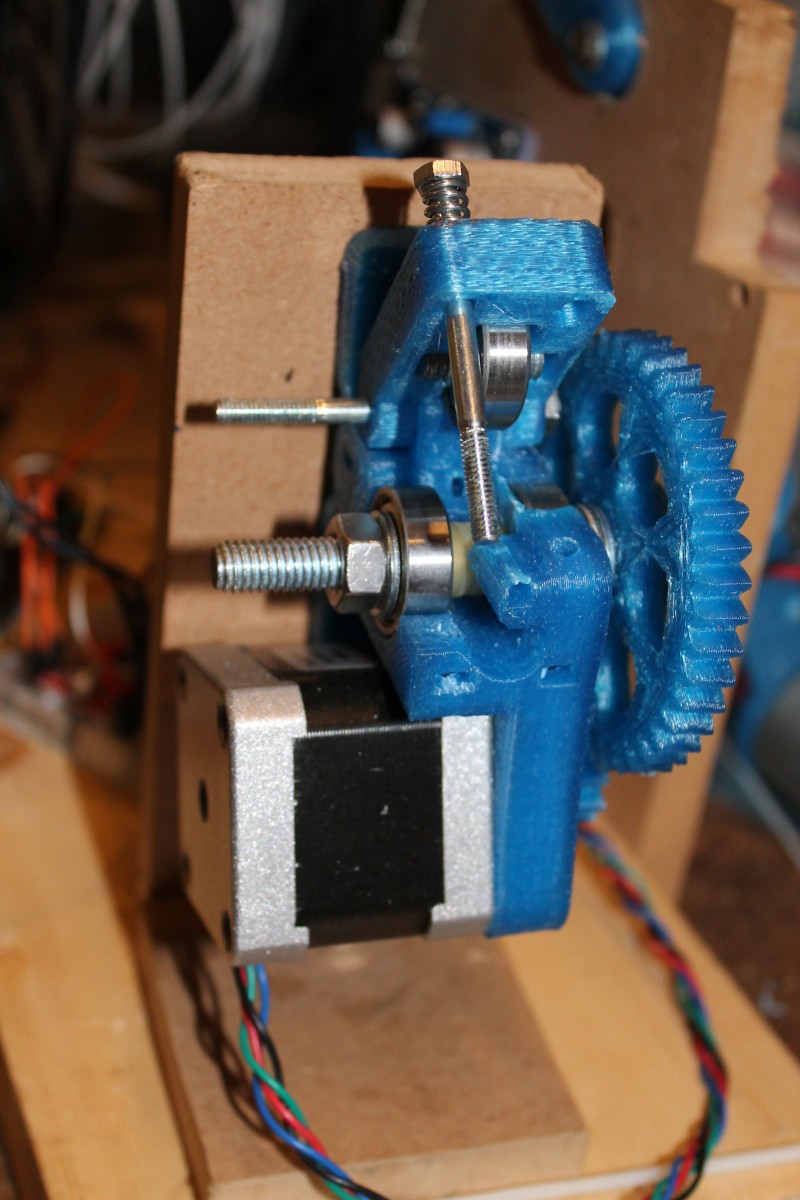

At our local meetup yesterday, a gentleman brought in his brand new extruder that he put together.

Bunch of other images I took in a zip here.

Well that is mighty interesting.

Did he build that gearbox himself, or source it from somewhere? What was the output speed like? Any other general impressions?

I think he hacked it together from a old powered screwdriver. At the meetup was his first actual time running it. It's speed was not constant but it didn't seem to matter to much. He wasn't using ABS pellet stock either, just grounded up black abs from previous prints. We did a quick check on it with some calipers on a couple feet that it ran and it seemed pretty good. His melt zone was right around an inch and the entire macine had a real small footprint. He was unlucky and got one of those counterfeit PID's that was off ~90C. He was using a cartridge heater and you could touch that first flange without getting burnt due to that heatsink. Carved teflon piece at the end to catch the filament.

that's a nice looking setup...

that's a nice looking setup...

Yeah, I'm really curious about it. It completely flies in the face of most extrusion texts - for ABS, they recommend L/D ratios of 18-24. The Filastruder's is about 14, kind of a compromise. His can't be more than 3 or 4.

He's also gotta be dumping a good bit more heat into the air than the Filastruder.

Let us know if you hear more once he's run it, or invite him to stop by the thread!

DePartedPrinter wrote:that's a nice looking setup...

Yeah, I'm really curious about it. It completely flies in the face of most extrusion texts - for ABS, they recommend L/D ratios of 18-24. The Filastruder's is about 14, kind of a compromise. His can't be more than 3 or 4.

3 or 4 is what was recommended to me, but 18-24 sounds better. I'm using a die size of about 3.2mm with my puller, drilling the hole straight through the plug without a countersink on the inside gives me a land 25mm long making the Land/Die ratio just under 8. When the plastic is compressed into the die, the elasticity creates stresses that get released when the plastic exits the die, creating die swell. If the land (thickness of the die) is longer, those stresses have more time to work out before the compression is released. That is why a longer land reduces the amount of swell.

It could be that the land on my 3.2mm die is short enough, and the forces within the plastic still disorganized enough that it isn't behaving consistently when leaving the die. I can try lengthening the land by drilling a brass bolt and threading it into the plug (I think Filabot looks like it does this). I can also reduce the needed land length by reducing the size of the die.

For pulling the filament directly to the roller, there is a minimum ratio of die size to filament size that I think will be effective. A small ratio means less tension to draw the diameter down a smaller amount. I'm finding that the more gentle the draw, the more the filament is able to move around on the way to the roller, rather than being stretched tight. The tendency to coil is still there, but with the drawing action it gets turned into a loose spiral as the filament travels from the die to the roller.

I think L/D usually stands for the length/diameter ratio of the extruder screw.

Another spec is the compression ratio (taper of the flute, basically) which is usually between 2.5-1 and 4-1.

I think L/D usually stands for the length/diameter ratio of the extruder screw.

Another spec is the compression ratio (taper of the flute, basically) which is usually between 2.5-1 and 4-1.

Right! That's how I was referring to it.

These screws have no taper, unfortunately.

jon_bondy wrote:Aluminatus

What made you go that route over the SD?

Hadn't seen the solidoole, and wanted a much sturdier structure than the prusa/mendel.

Someone (Ian?!?) pointed me at the Aluminatus, and I somehow fell in love. 12" (300 mm) cubed build volume. Print speeds almost twice that of the SD. LCD controller. Lead screws for all axes, with anti-backlash. Fully open source. It's more money, but I ruin about 1/2 of the prints that I start with the SD because it is unreliable. Perhaps I'm dreaming, but I'm hoping for higher quality and reliability. I also have some projects that could use most of the build volume.

On the down side, there is no enclosure, and no plans for one. The design may making an enclosure large and difficult.

The user group is active and interesting. Lots of interest in printing nylon, most people already have multiple printers.

The SD served it purpose: I now understand 3D printing much better, with an investment that was reasonable, given that I started out knowing nothing. Now, on to more serious machines.

jon_bondy wrote:Aluminatus

What made you go that route over the SD?

How do you clean out the extruder? Do you just tilt it up, and raise the temp a little? Do you pour acetone into it? What do you do to be able to unscrew the nozzle?

Run it til empty and then load in your next pellet stock and purge for awhile until your filament is what you need. There doesnt seem to be a super quick way to completely purge the setup currently. So it might not be super useful for doing small batches of different colors.

How do you clean out the extruder? Do you just tilt it up, and raise the temp a little? Do you pour acetone into it? What do you do to be able to unscrew the nozzle?

Yeah, let it run until empty. There will still be some plastic left between the end of the screw and the nozzle, that will get pushed out by the next run you do.

Cross-conatmination ranges from 10-100g, depending on what you're switching. Black to clear is the worst, I had to push about 100g before it completely flushed the black.

Hey Nick!

Thanks for posting up those pics. I'll be shooting video today of my extruder, and will run a couple of prints with the filament.

I think my L/D is closer to 8. 1/2" auger at 4" length.

Think I have my PID better tuned, and the varying motor load is from the recycled feed material density.

I have a pinch point between the auger and the edge of the feed slot that would probably not be a problem with actual pellets.

Hey Nick!

Thanks for posting up those pics. I'll be shooting video today of my extruder, and will run a couple of prints with the filament.

I think my L/D is closer to 8. 1/2" auger at 4" length.

Think I have my PID better tuned, and the varying motor load is from the recycled feed material density.

I have a pinch point between the auger and the edge of the feed slot that would probably not be a problem with actual pellets.

I still smash/slice pellets in half at the same pinch point.

I would recommend adding a pipe wrench to the tools needed for assembly. When I put the new 8" nipple on, I screwed it in tight, slid my hopper onto it and marked where I needed to cut the opening. Once it had fed enough plastic to start extruding, the auger managed to screw the nipple in almost 90 degrees more than I had managed by hand. Fortunately there is still just enough of the opening exposed to for the pellets to go in. I could turn the flange 90 degress the other way, but I would have to disassemble almost everything to do it.

So before marking where you will cut the opening for the hopper, it's a good idea to first screw it onto the flange as tight as you can with a wrench, and not just hand-tight.

I would recommend adding a pipe wrench to the tools needed for assembly. When I put the new 8" nipple on, I screwed it in tight, slid my hopper onto it and marked where I needed to cut the opening. Once it had fed enough plastic to start extruding, the auger managed to screw the nipple in almost 90 degrees more than I had managed by hand. Fortunately there is still just enough of the opening exposed to for the pellets to go in. I could turn the flange 90 degress the other way, but I would have to disassemble almost everything to do it.

So before marking where you will cut the opening for the hopper, it's a good idea to first screw it onto the flange as tight as you can with a wrench, and not just hand-tight.

You got it! I agree, I screw it into the flange as tight as I can without a pipe wrench, but one would help.

Ian and the other guys: Can you shoot a short video of your extruder, now that its converted?

Just some quick notes:

I used to use LDPE (low density polythene) to purge my injection moulding machines between changing plastics. It helps to use something that isn't too runny to scrub the machines.

Plastics generally don't like staying in the molten state for too long and start to degrade.

You could use the extruder mechanism from a reprap as a haul-off.

Make sure it doesn't grip too tight though or the surface of the filament will have marks on it and won't push through bowden tube feeds so easily.

I would use low melt index plastics (not very runny) as the material stock because I think it should print overhangs better and drool less.

I am currently using an extruder for the haul off, the Gregs Reloaded. This is an earlier version-

I'm having trouble figuring out how to grip the filament. Latex isn't working because changes in filament diameter change the compression of the rubber, which changes the effective diameter of the roller. I tried coating the bolt in Plasti-Dip, but it was quickly shredded. I have a hobbed bolt on order, I'm hoping that I can use a light enough grip that won't mark the filament. There doesn't need to be a lot of torque since the filament isn't getting forced against an extruder's back pressure. If that doesn't work, I will try molding a roller from a rubber hard enough to resist compression.

One advantage to using an Arduino and a stepper for haul off is it can easily keep count of how much filament has been spooled.

Just some quick notes:

I used to use LDPE (low density polythene) to purge my injection moulding machines between changing plastics. It helps to use something that isn't too runny to scrub the machines.Plastics generally don't like staying in the molten state for too long and start to degrade.

You could use the extruder mechanism from a reprap as a haul-off.

Make sure it doesn't grip too tight though or the surface of the filament will have marks on it and won't push through bowden tube feeds so easily.I would use low melt index plastics (not very runny) as the material stock because I think it should print overhangs better and drool less.

Agreed about the plastics being molten for too long. You can see darkening/discoloration if you run the heater for more than 30 minutes without the auger running.

The tradeoff between low MFI and high MFI is print speed vs. overhangs and dripping. For most of what I do, I prefer higher MFIs.

Markx, did you use precolored pellets for injection molding, or did you use masterbatch? What did you usually do with the leftovers? The minimums for buying from manufacturers are way too big, it seems the best source of colorant for home extrusion may be asking molding and extrusion companies for their leftovers. Any advice on how to go about this without getting ignored?

SoliForum - 3D Printing Community → Filastruder → Filament Extruder - Convert pellets to filament

Powered by PunBB, supported by Informer Technologies, Inc.