Interesting. I've seen multiple people running the E3D v6 fan on 5V, so I assumed it was 5V, but it looks like you're definitely right and it's meant to be 12V.

I wired it all up last night, and after a dealing with some shoddy crimping work, zip-tying the entire world, and MacGyvering a flag for the endstop opto-sensor because my printed flag was 2mm off, the thing actually printed. I still have that list of issues, but the version-zero carriage seems good enough that I can use it to print version one as long as I keep the speeds low enough. The hotend fan spins fine on 5V and the temperature graphs looked fine, although my attempt at a PID autotune timed out for some reason.

Interestingly, I actually had to raise the bed when leveling. I know I want to lower the extruder a bit in in the next revision so the entire heater block clears the bottom of the carriage, but it does look like I avoided losing build volume in the z-axis. On the other hand, the hotend is right of center on the carriage because of how the Titan is laid out, so I may be losing volume in the x-axis instead. Hard to say now because my workaround for the bushings I'm using now makes the carriage wider than it needs to be.

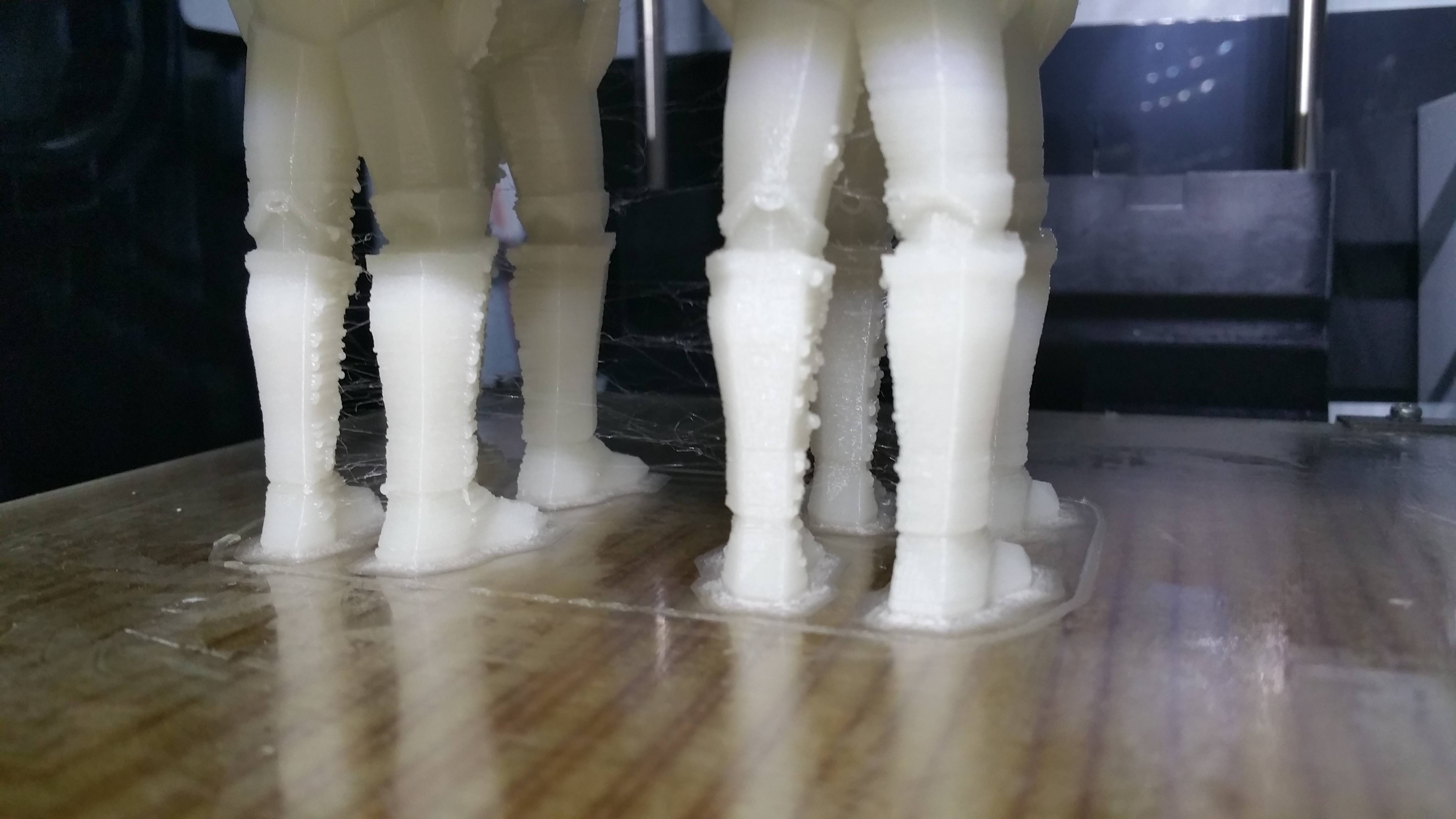

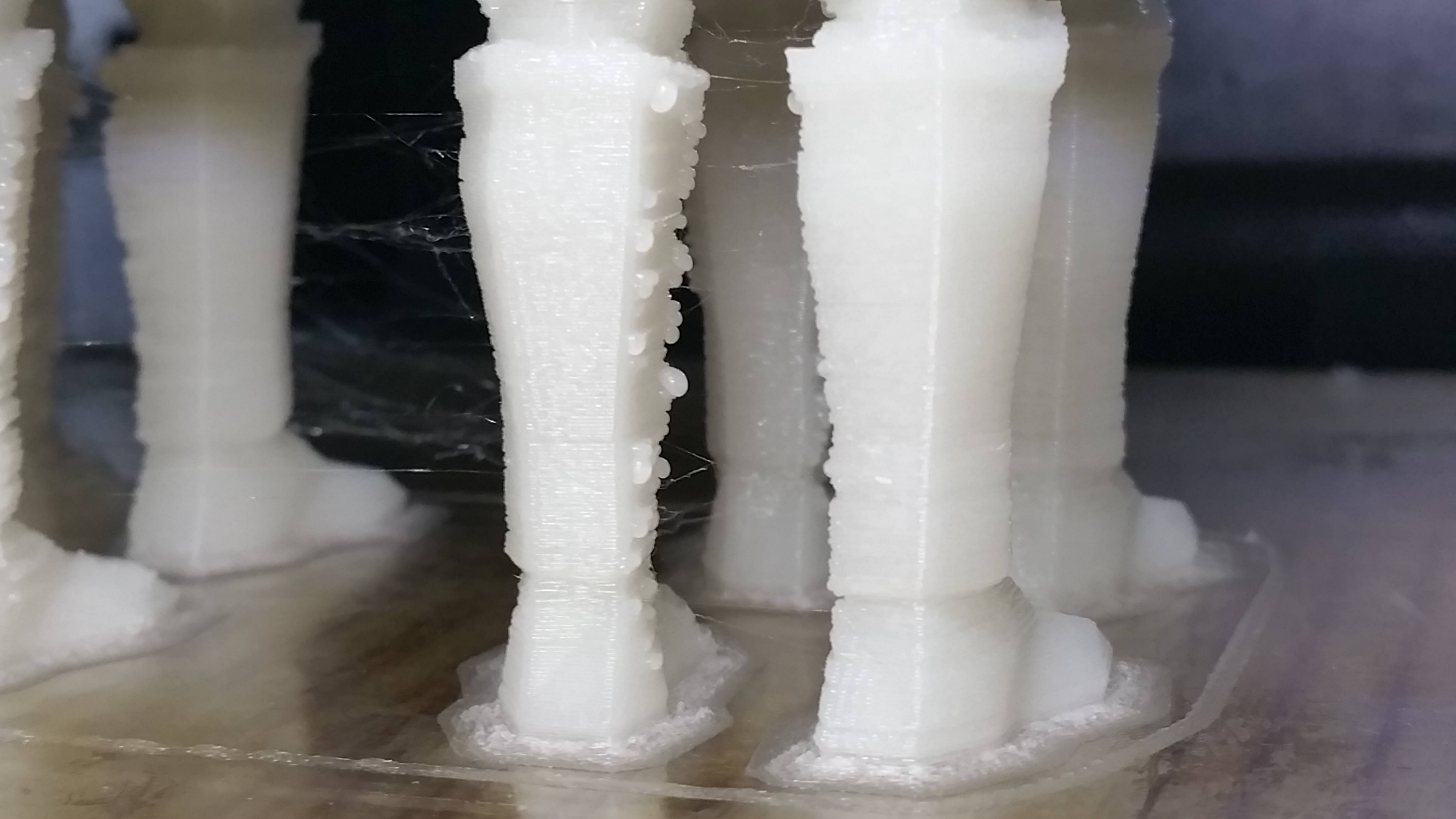

The biggest issue I'm having is just ABS warping. Without kapton tape, I would reliably see corners peeling off the plate as expected. With it, the corners stay down but I see quite a bit of shrinking in the layers of the first 10mm or so. This is causing me all sorts of fun when trying to get the bearing holes right because sanding them inevitably makes them crooked. I'm thinking I'll play with my temperatures a bit and see if the problem improves, but does anyone have any thoughts?