Topic: Davinci Junior Filament Stepper clicking

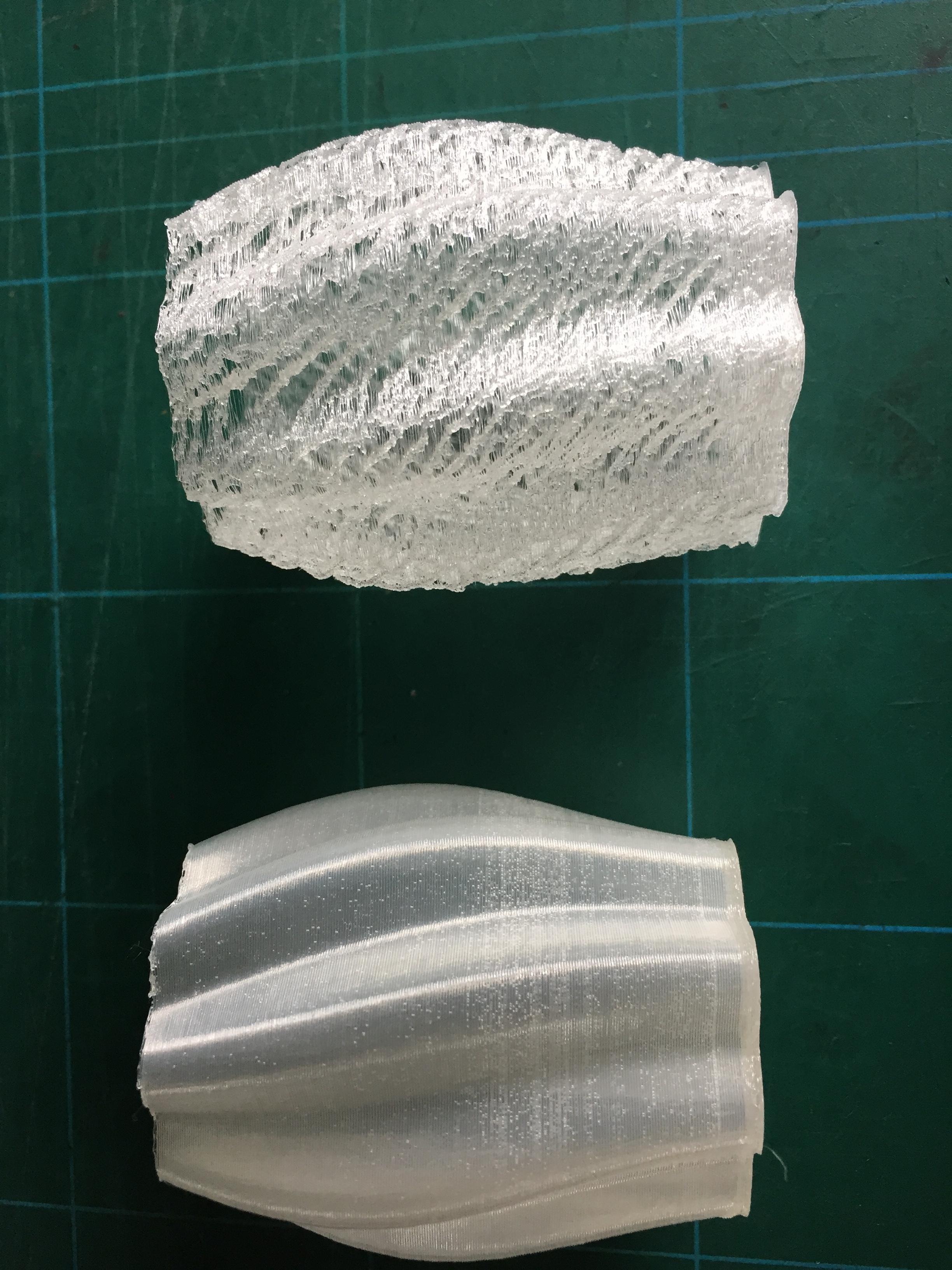

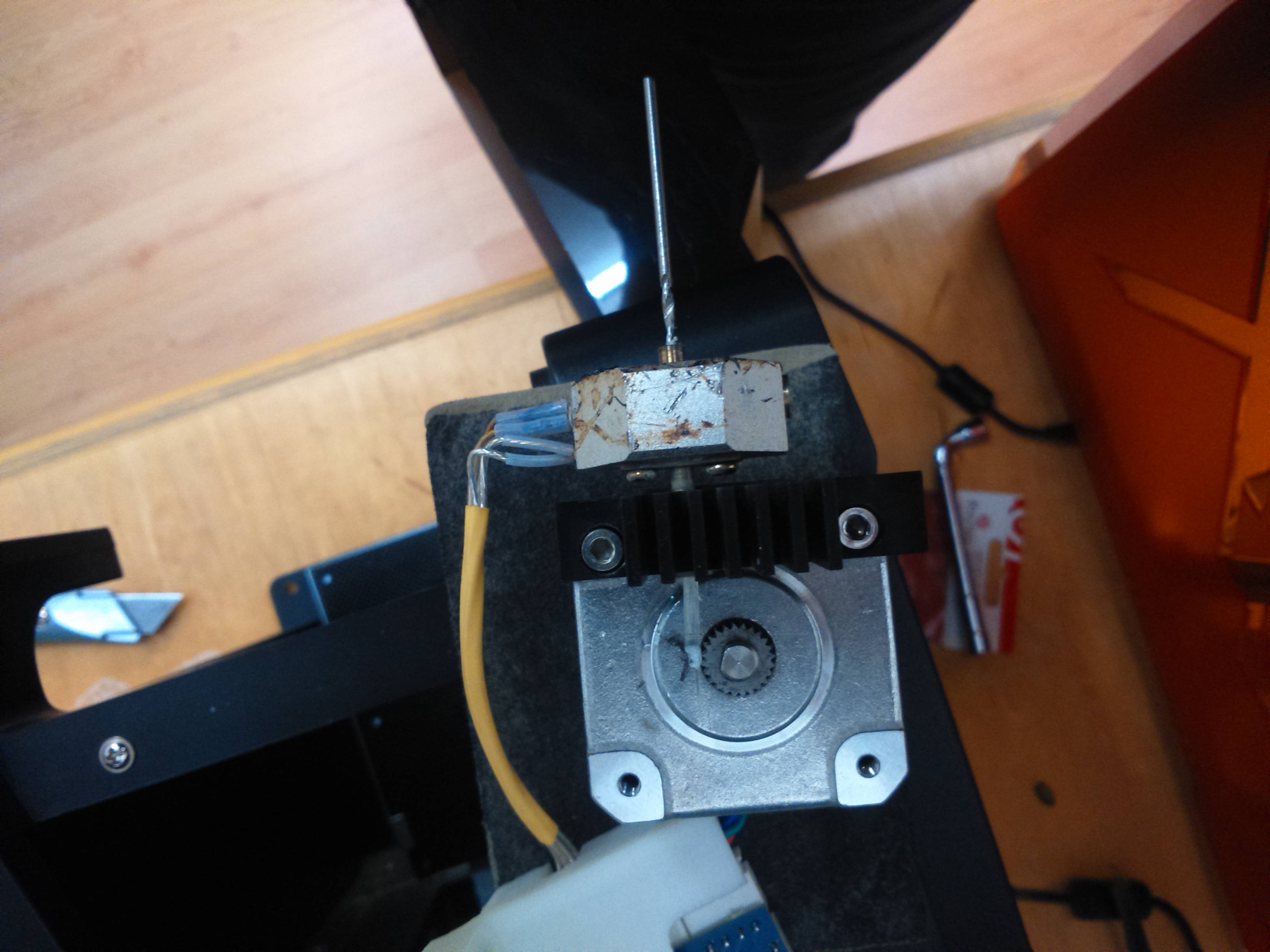

Hello! I just bought my first 3D printer this week, the Davinci junior, because I wanted something simple to start with. I got it setup pretty easily and was able to print several objects that have so far worked out perfectly. That is until Saturday, I tried to print a simple vase but the printer wasn't acting normal. I noticed that the filament feeding motor on the upper left side was clicking during the beginning of the printing process for my frist couple prints (that turned out good) but stopped after a few minutes. Not knowing if this was normal or not I let it do it's thing. The prints came out pretty good but when I tried to print that simple vase it was clicking a bit louder toward the beginning of the print and laid down only one small layer of filament onto the print bed then continued to print as if it was extruding someting but it never extruded anymore filament. I tried a couple different files and they all did the same. I was thinking perhaps the extuder was clogged so I cleaned it out and it laid a better first layer but then started running throught he print without extruding anything.

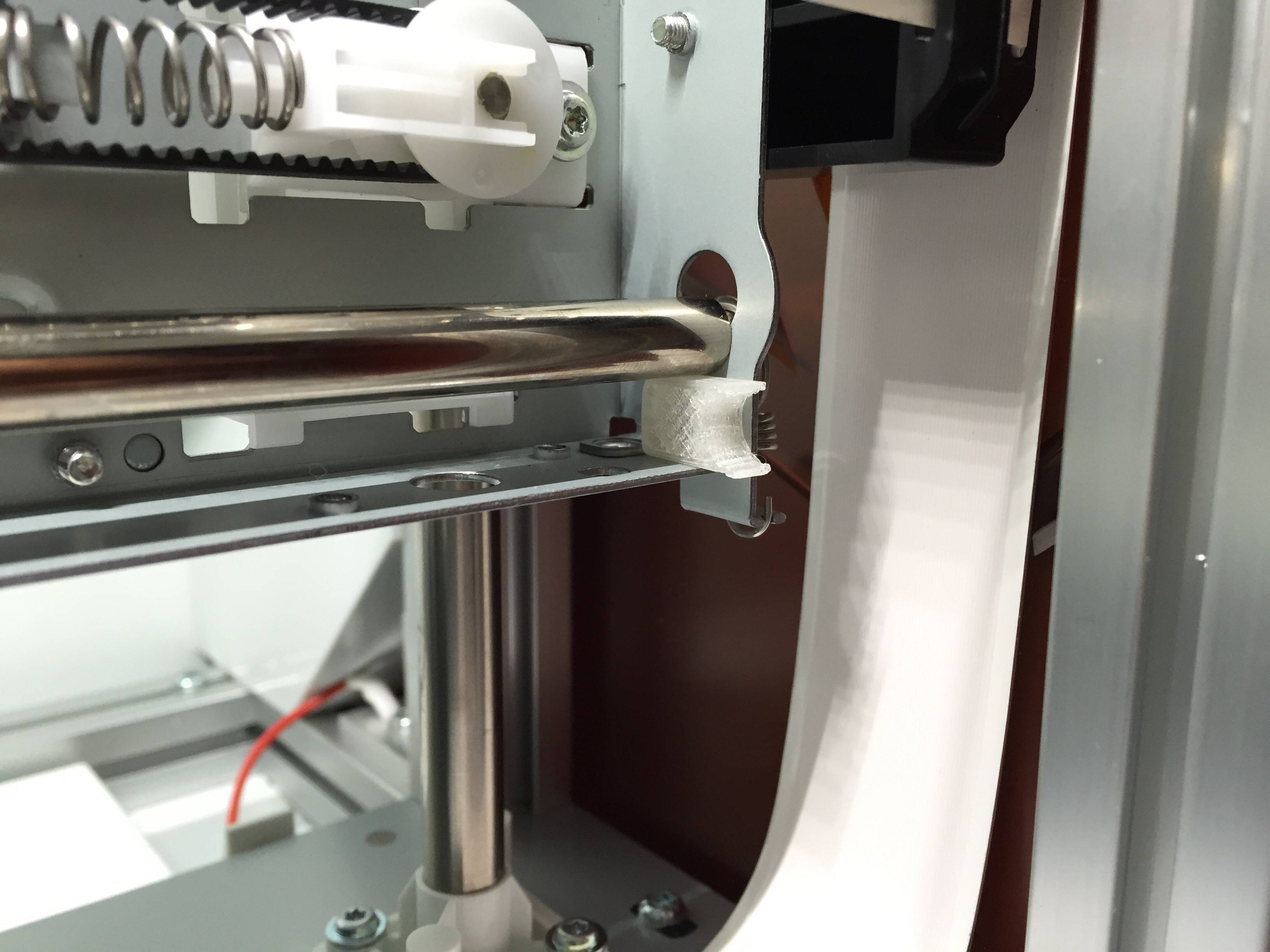

After some research I think that maybe the Z-axis is not set right anymore somehow, perhaps it never was. I played with it and the factory setting was 1mm so I put it to 1.2 and it was able to print an entire object that is about 1/2" tall but it still was clicking in the filament feeding area and the print itself was a little sloppier than the others so I'm wondering if I need to set the Z-axis higher still.

I contacted xyz to see if they could help and they suggested sending it in for evaluation, and this kind of made me mad because I've had it 5 days and now I have to spend $50 plus dollars to ship it back! I already got rid of the box it came in, big mistake. I would rather see if it's something I can fix with an adjustment rather than something being broken. I told them I wanted to talk to a technician first before sending this thing in.

All help is appreciated!