Re: Davinci Junior Filament Stepper clicking

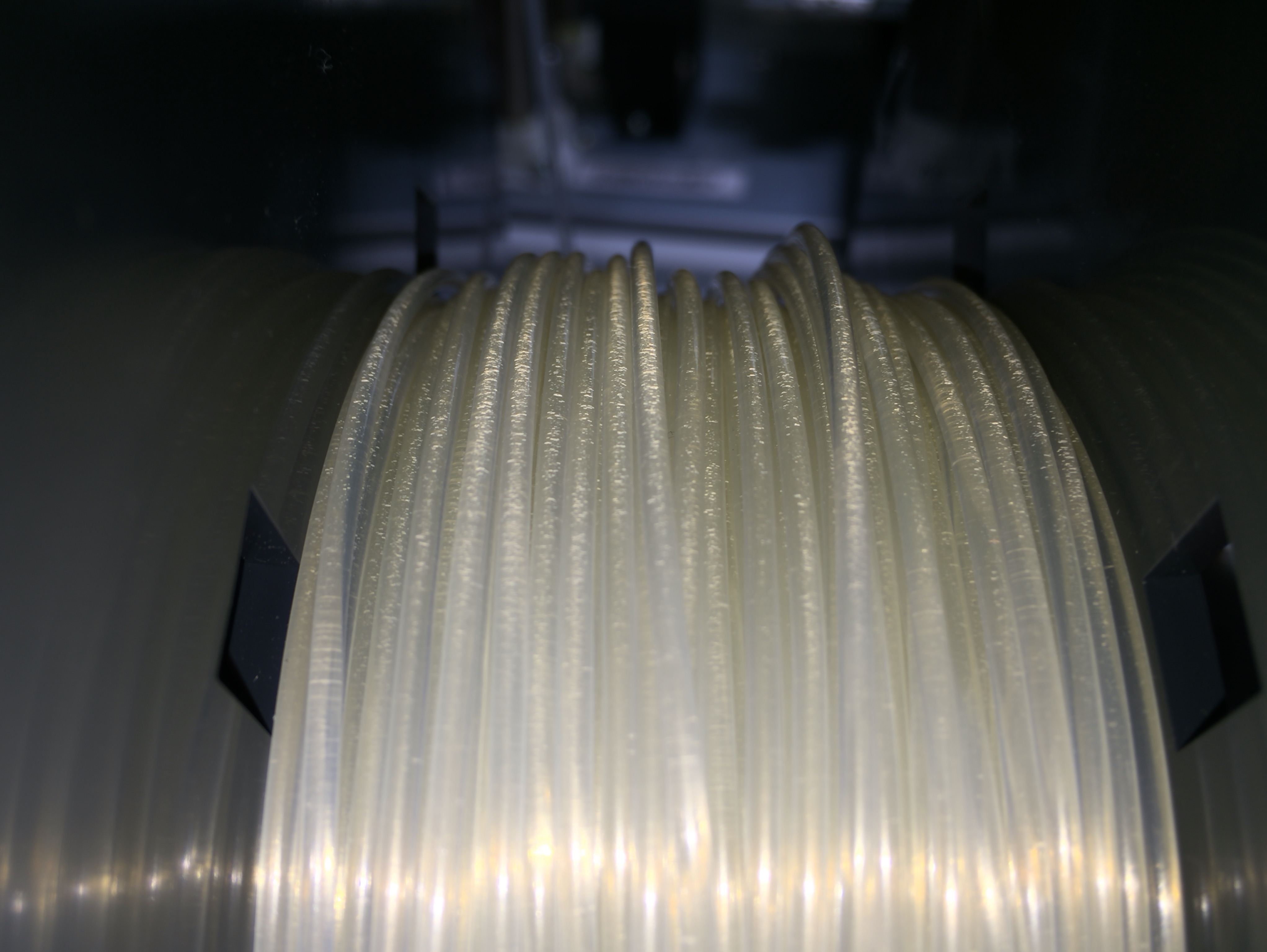

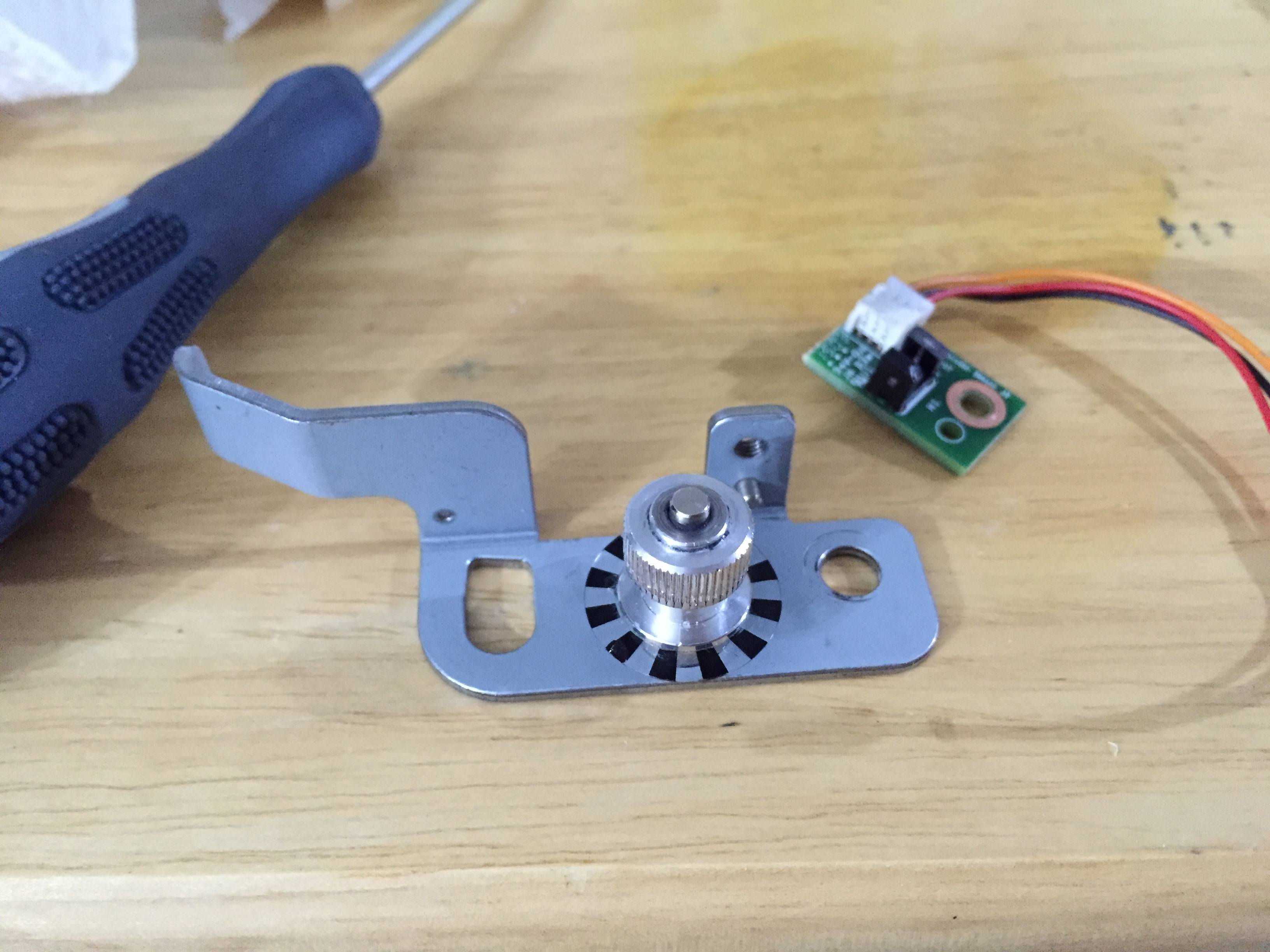

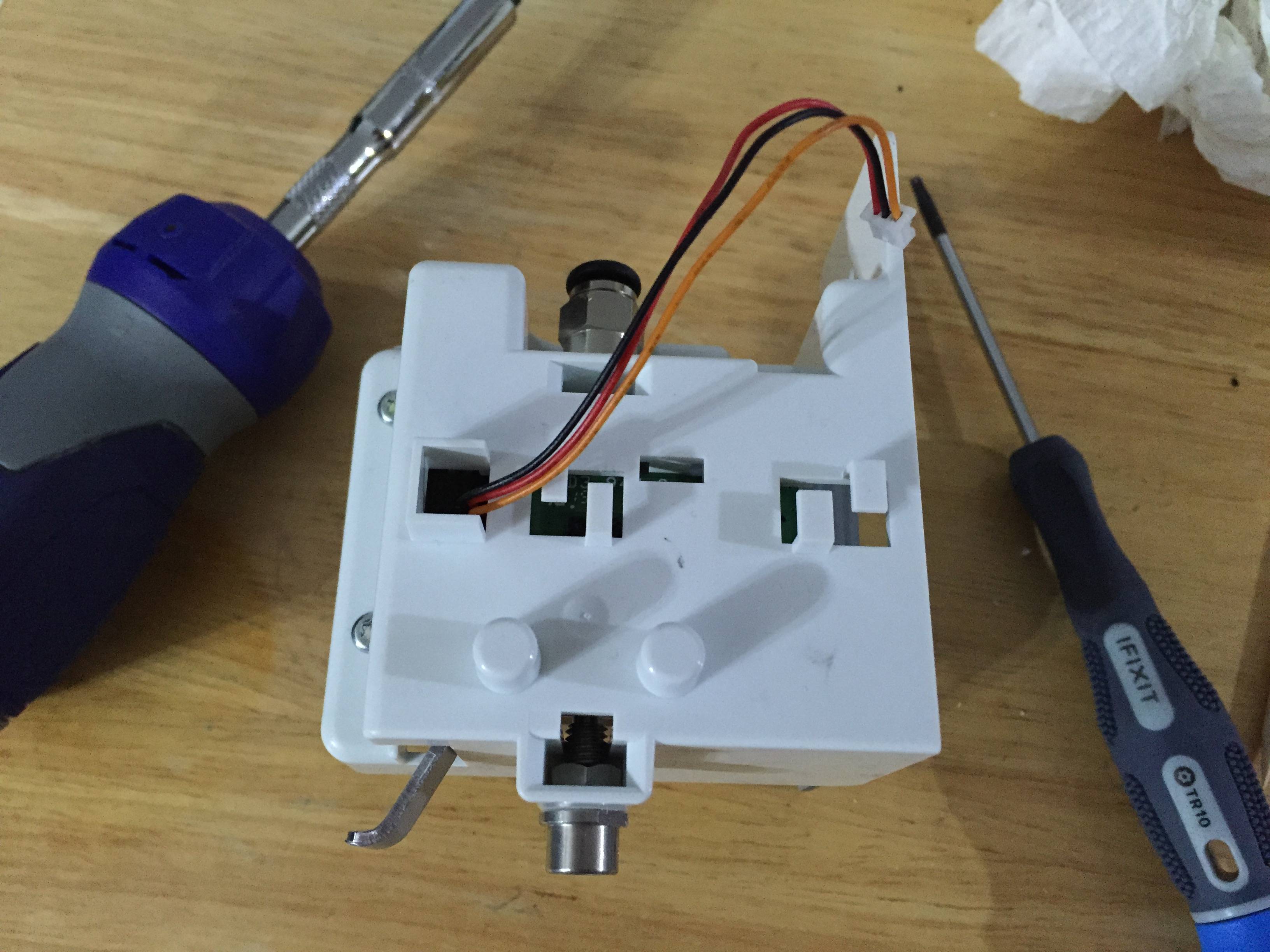

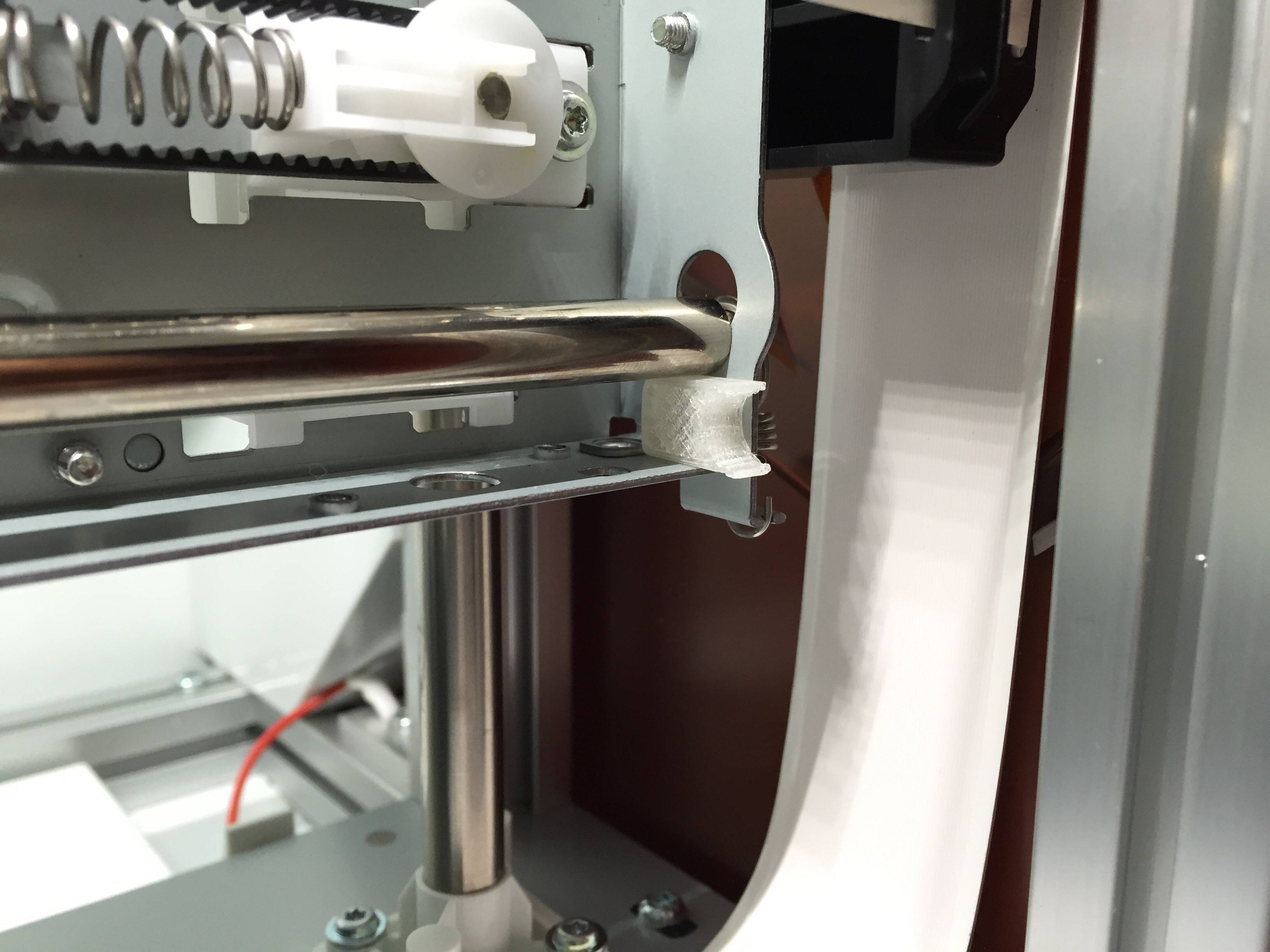

I recently got the XYZ Junior as well and one of the main problems with it is the x-axis arm not being level. The bed on mine is level but the x-axis arm has less support on the right side which causes it to lean downward on the right side. I noticed it after prints were tearing the tape to the right on the print bed and after messing with z-axis offset. I thought no user intervention was needed for calibration :-/ There's no way to fix it through the control panel or software app so I found another way to fix the issue. I noticed that the rod the print head moves on is not bolted in place. It is held in place by springs and can be moved up. I placed a printed support (8.58mm tall) under the rod to the far right to make it level with the bed. Then I adjusted the z-axis offset again to make sure 2 sheets of copy paper fit between the print head and bed throughout the x-axis length. Now the print head and bed have good spacing just about everywhere. The other issue which others have talked about is the subpar PLA filament that xyzprinting includes and forces you to buy because of DRM. The filament looks really horrible and I'm sure is mostly to blame for the jamming we are all experiencing. Mine mostly starts clicking at the beginning of a print but not all the time. It also occurs more at higher print resolutions. I have been able to successfully print many items though and with great quality. Xyzprinting says DRM is necessary to make sure issues are kept to a minimum and for easier troubleshooting but they give us mediocre PLA and charge more for it. How does that make any sense? It's all about more money in their pockets. Someone needs to figure out how to bypass the NFC DRM to allow us all to use high quality materials at fair prices!!!

Was your spool labeled PLA? Many have received spools that are labeled ABS. If you try to print you will jam as the junior gets no where near the temp for ABS. If it smells like melted plastic while printing it is ABS. PLA will smell like burning sugar.

Anycubic 4MAX best $225 ever invested.

Voxelabs Proxima SLA. 6 inch 2k Mono LCD.

Anycubic Predator, massive Delta machine. 450 x 370 print envelope.