heartless wrote:make the needed changes in the firmware, and re-flash - not hard at all.

If the OP has re-flashed his controller with sailfish, he should be able to make the changes needed and re-flash again... If - for some unknown reason - it cant be done, then i would seriously get away from that particular style of controller board and go with something that is much more configurable - ramps, rumba, printerboard, any number of others...

There should be NO reason one cant make the required changes in their firmware. If the Company is not giving you access to the actual firmware used that is a whole different issue. Have you ever asked for the actual firmware itself?

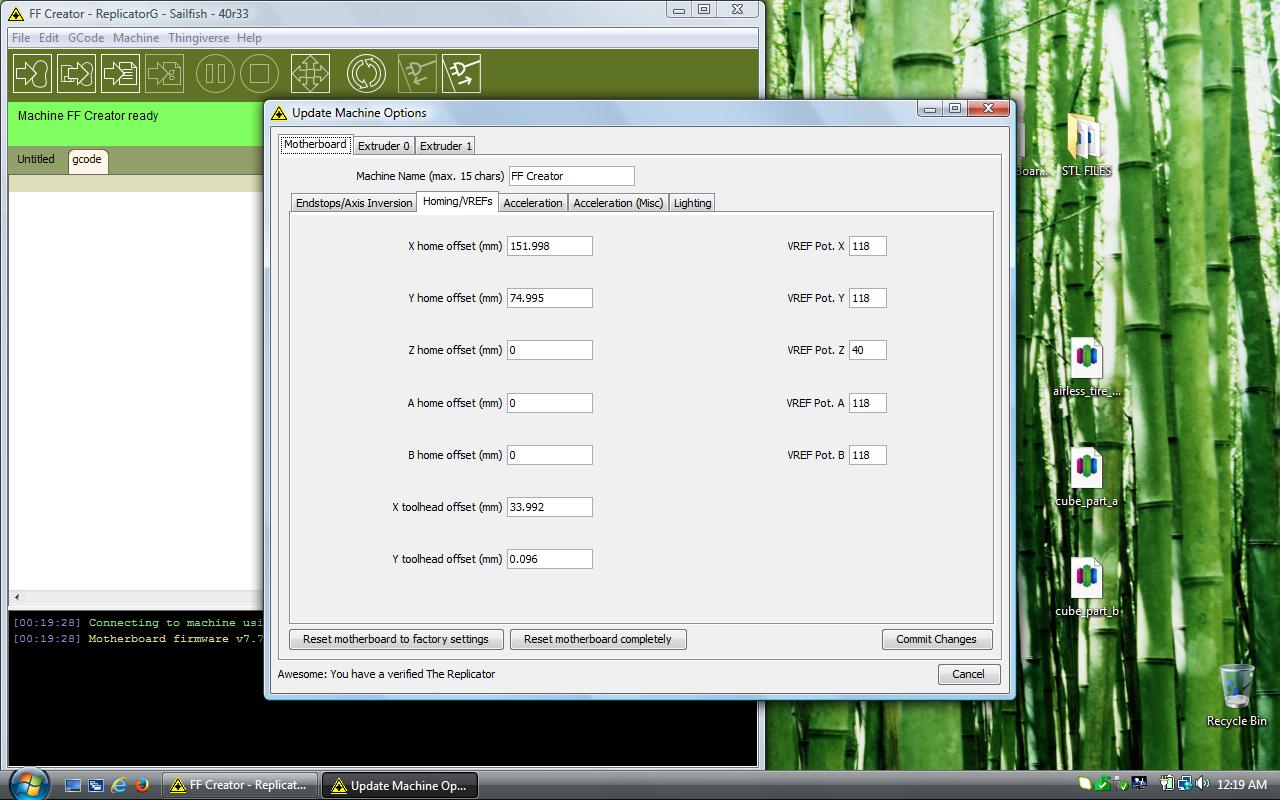

Sailfish is a modified version. But it is supplied as a .BIN file, not a zip. In order to flash the mightyboard you have to use replicatorG which has AVRdude builtin and it loads the .BIN file. Your option is to JTAG the firmware using Atmel Studio and a JTAG adapter. Again this uses a .BIN file. That means the file is precompiled and you are limited to what the sailfish creator decides for you aside from it is available through the limited access to some values such as offsets and a few other settings. Unless you know what software was used to compile the .BIN file which is not shared then it is near impossible to decompile it and edit it then recompile.

There is a reason why there is not a big firmware community for makerbot/flashforge/CTC mightyboard based printers.

Even the stock version supplied by makerbot is still a .BIN file that you would need to decompile in order to edit and again without know what it was compiled on your shances are very low of being successful.

When you update firmware on the CTC or similar models it is done from a URL that is setup in ReplicatorG. That URL supplies the BIN file, you don't download it yourself from somewhere like most printers. There is also some sort of validation done to verify the URL is correct before the process starts so there is some sort of security in place as well.

Since you never actually have access to the .BIN file decompiling it really is not even an option.

I have searched high and low on ways to make internal firmware changes for a mightyboard as there is nothing I would like to do more. There are some settings that really bug me and I would like to change them as well. But you can't unless you make and compile your own version.

Printing since 2009 and still love it!

Anycubic 4MAX best $225 ever invested.

Voxelabs Proxima SLA. 6 inch 2k Mono LCD.

Anycubic Predator, massive Delta machine. 450 x 370 print envelope.