thanks for this information.

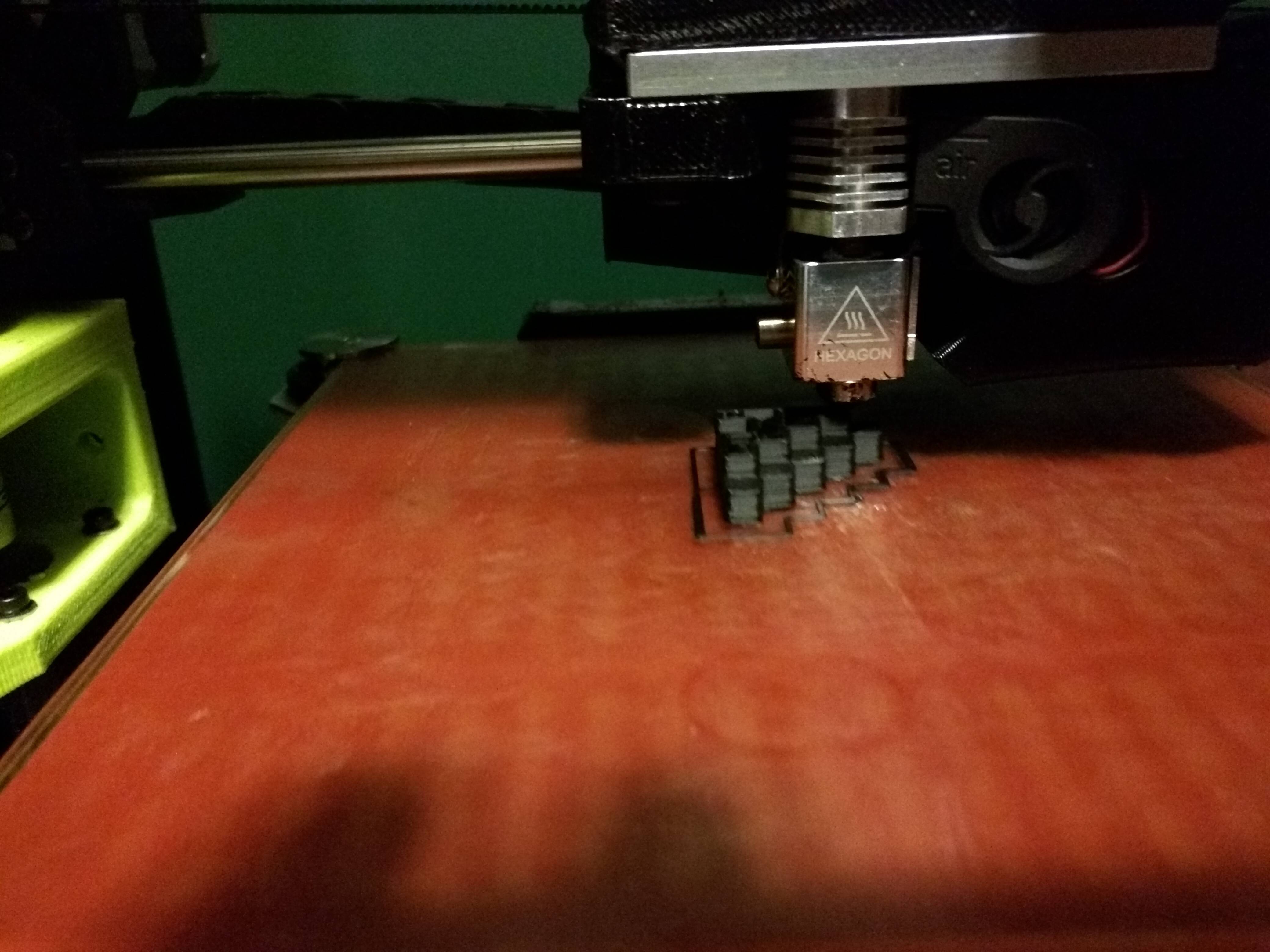

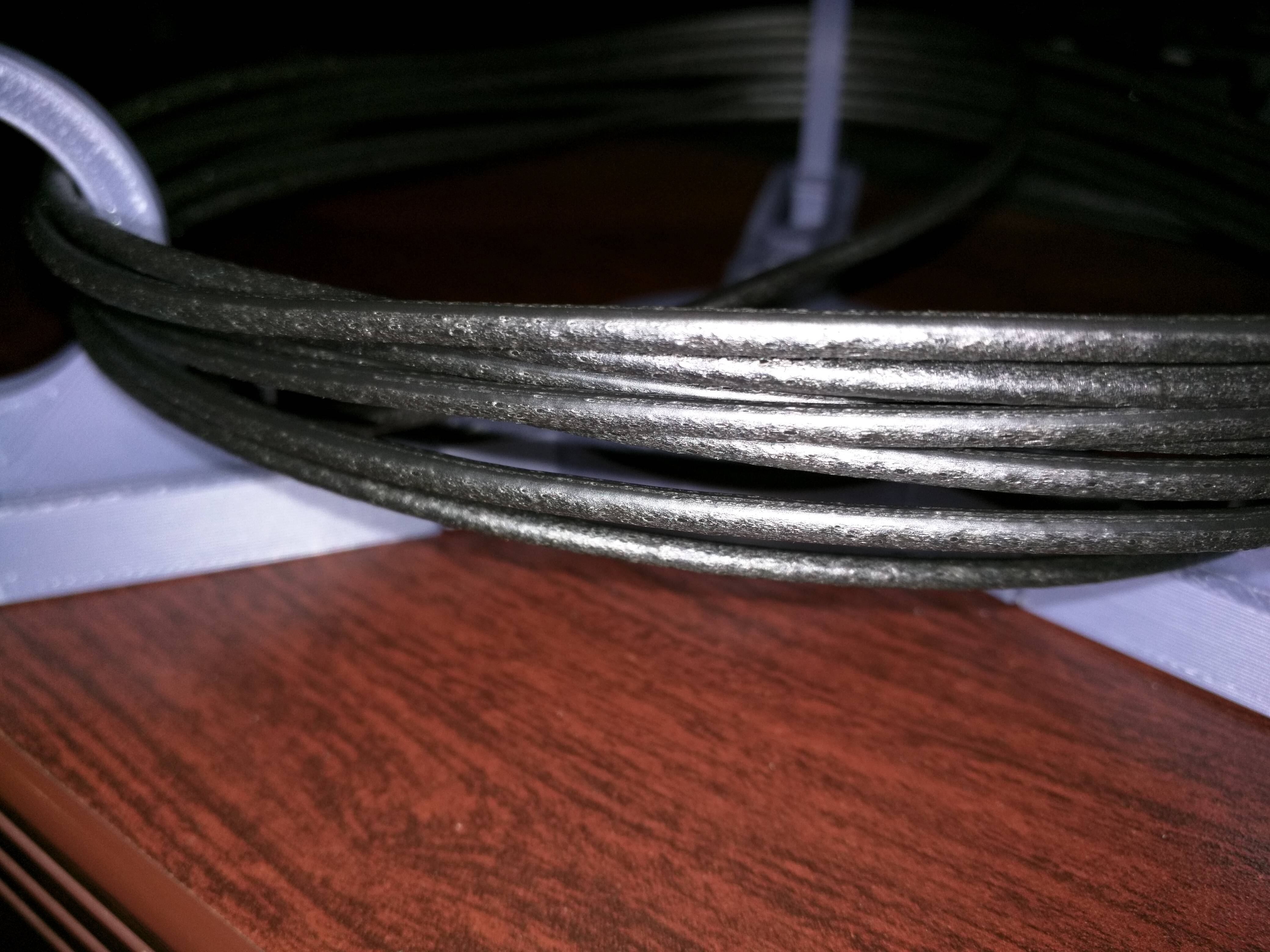

Nylon 645 properties and characteristics

645 is currently being used by CNC shops around the world to support quick turn prototypes for Pre-Pilot and Pilot runs as well as some limited production runs. As global supply compresses and just-in-time becomes just-a-little-late, more and more CNC shops are jumping in to fill quick turn needs.

645 is machinable with similar settings and cutting speeds as used in Cast Nylon blocks.

Thermal properties are slightly higher than Nylon 6,6 and Nylon 6,12.

Cutting tools need to be sharp.

Three flute flat end mills are preferred.

Holes to be drilled should be printed the next metric or imperial size down and no less than two perimeters when printing. A calculation should be

made such that drilled holes do not encroach on fills and be contained within perimeters only.

645 does not leave any nylon dust residue during tap operations. However, 645 does cut and even with it's slippery properties, some "cuttings" can

be retained in the tap'd hole, therefore, these should be cleaned using compressed air.

For tap'd holes that are used for threaded rod, where the rod will be constantly rotated, do NOT use any lubricants as they are not needed and over

time will be soaked up into the fill area.

Locking chemicals for blind nuts do NOT work on 645, and as some contain acids, they will weaken bonding.

Tap quality and material thickness follow the same rule as for aluminum.

Threaded Brass Inserts work well when installed with a soldering iron set to 250C

Do NOT use water based solvents as 645 will take on some of the solvent and become discolored. - Permanently!

Nothing bonds to 645. To adhere other parts to 645, they must also be made of 645 and bonded with a heat gun or soldering iron.

Pliability of 645 follows the same size and density rules that apply to injection molded nylon for 100% fill parts.

For more pliability, you can reduce fill to something less than 100%

3d printing service chennai kolkata india

thanks

visit:http://vexmatech.com