Re: XYZprinting Da Vinci 1.0 Hacking

Hi,

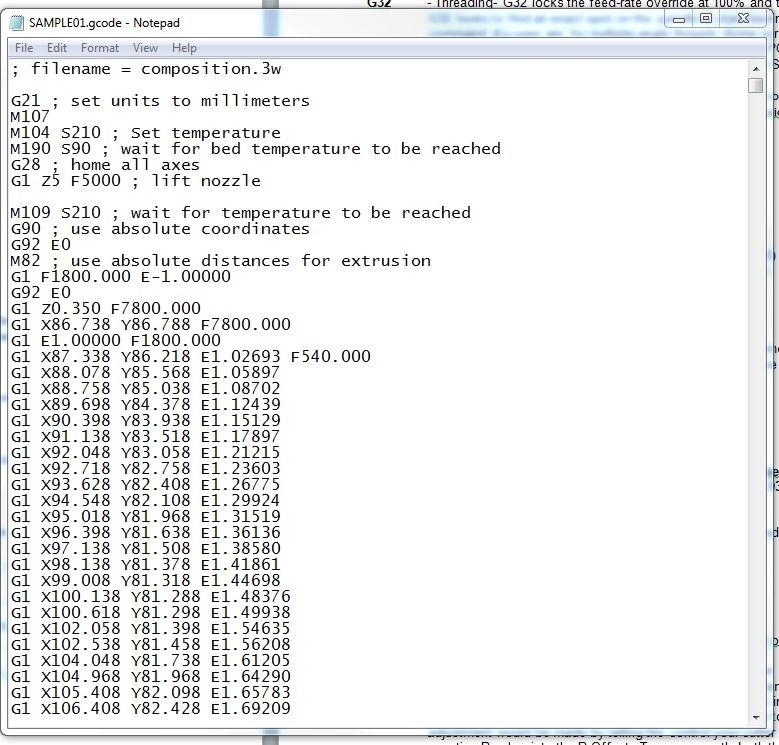

I am using this hack as the XYZ software is making my models come out rubbish. I have a question, when exporting the gcode from slic3r and opening it up in notepad++ I am getting a different set of commands compared to everyone else:

; generated by Slic3r 1.1.2 on 2014-05-07 at 16:05:14

; perimeters extrusion width = 0.40mm

; infill extrusion width = 0.67mm

; solid infill extrusion width = 0.67mm

; top infill extrusion width = 0.67mm

G21 ; set units to millimeters

M107

M190 S100 ; wait for bed temperature to be reached

M104 S230 ; set temperature

G28 ; home all axes

G1 Z5 F5000 ; lift nozzle

M109 S230 ; wait for temperature to be reached

G90 ; use absolute coordinates

G92 E0

M82 ; use absolute distances for extrusion

G1 F1800.000 E-1.00000

G92 E0

G1 Z0.250 F7800.000

G1 X87.534 Y88.934 F7800.000

G1 E1.00000 F1800.000

G1 X88.057 Y88.489 E1.03416 F540.000

G1 X88.715 Y88.027 E1.07416

Should I still keep these first few lines of gcode?

; perimeters extrusion width = 0.40mm

; infill extrusion width = 0.67mm

; solid infill extrusion width = 0.67mm

; top infill extrusion width = 0.67mm

If I should still keep them, where should I add the XYZprinting details?

Thanks,

Leigh