Re: Filament Extruder - Convert pellets to filament

The washer in the socket didn't work out for me -

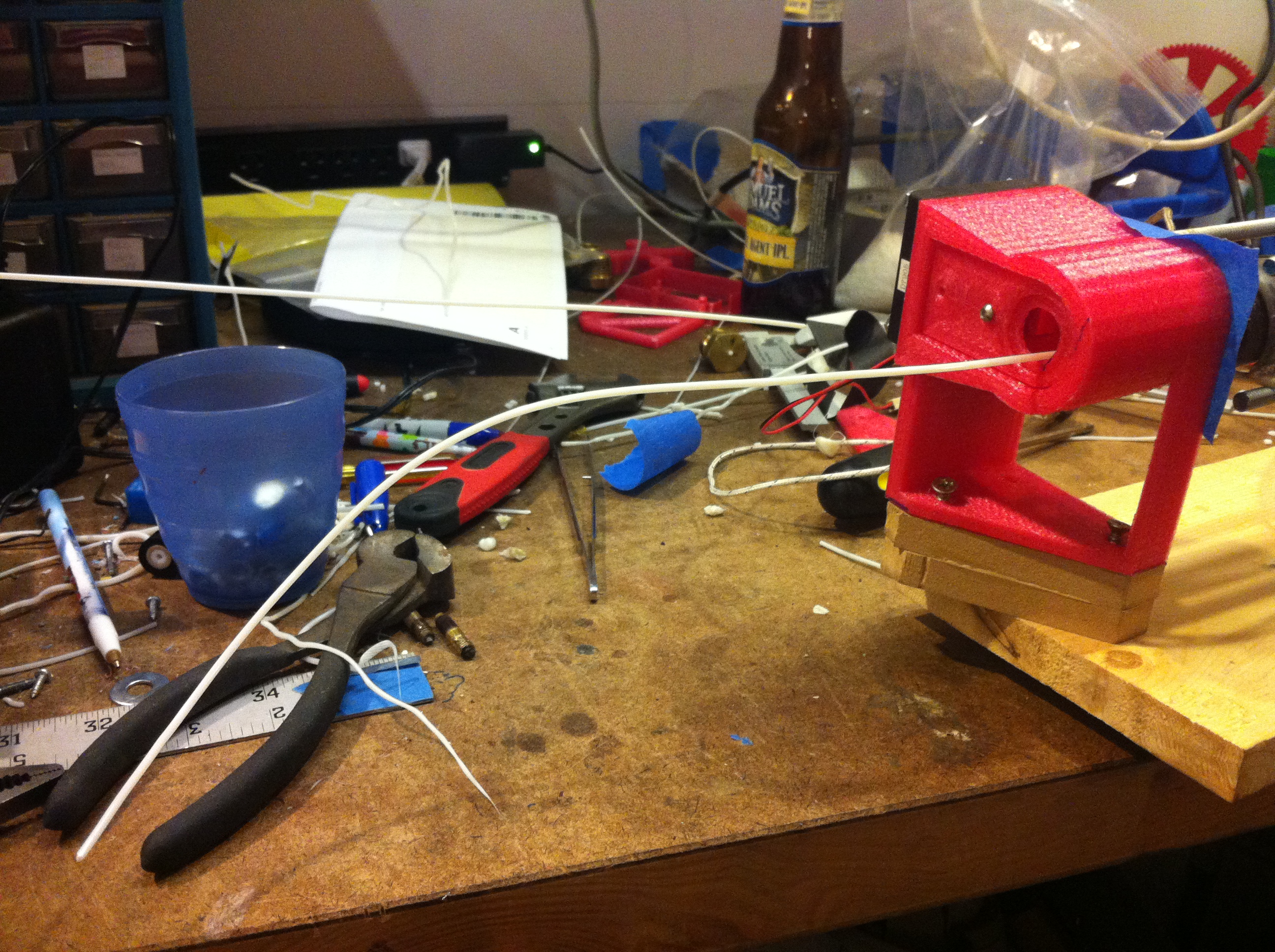

I finally figured out how to drill a #52 bit all of the way through a 30mm brass bolt without breaking it. Since I have 6mm brass bolts that fit a PEEK hot end insulator, I drilled one through with the #52 bit and used it to attach one of the spare insulators I have laying around to the plug. I was hoping that filament would swell to the usual 1.7 or so and push through the insulator as it is cooled and held steady. There is enough friction inside the insulator that the filament came out at 2mm, but it only varied .03-.05mm. I put most of the insulator inside the fan duct, and the temp at the plug dropped to 175 and stayed no matter where I set the PID. I pulled the duct back so only the end of the insulator was inside and the temp rose to 185.

The filament was only extruding about 2-3"/min, but it went almost 18" before it even touched the workbench. It can definitely be handled without problem. I'm going to make another try at a 1.7mm cold end, since this approach shows promise.

Before I put on the PEEK, I tried extruding through the bolt by itself. If the bolt was cooled, the extruder couldn't get the plastic out. It might be worth experimenting with that some more, but I think it will take another thermocouple at the end of the bolt and speed control on the fan to find the right temperature.

I got the spring washers, but foolishly ordered 5/8" ID, because you know, the auger is 5/8". The shaft however is 3/8". I put them in anyway, in 3 pairs oriented to have 350lb max load. I didn't see an improvement in accuracy, but if I heard the motor start to struggle, I could look over and see them start to compress. I'm not sure exactly what benefit they would have, but I have a feeling they would be a good addition. I'll look into it more once I have the right size.