Topic: Replacement hot end

Going on from this thread:

http://www.soliforum.com/topic/441/heater-resistance/

I'd like to know peoples opinions on the best/easiest upgrade for the hot end.

I had my second blockage but when I tried to pull it apart to do the blow torch trick (which worked great the first time), the ceramic around the nichochrome wire had fractured and gone everywhere. Furthermore, Ibecause I can't get this off, the clog remains and my printer is rendered useless.

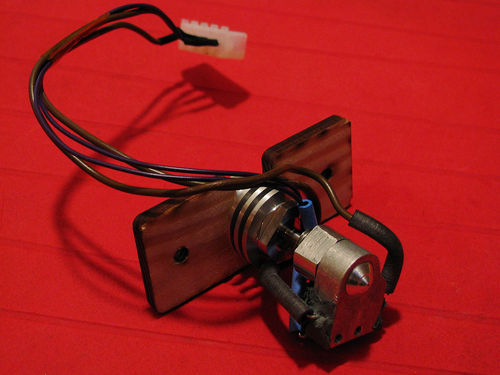

I think a hot end that has a metal block where the heating resistor sits inside along with the thermistor is ideal, as the brass tube and nozzle can be taken on and off without any risk of damage:

One other frustration is that the peek insulator is round and has nothing to stop it spinning when taking off the nozzle. I've filed two flat sides on my peek barrel so a spanner can stop this. Ideally, I'd like to be able to remove and clean the nozzle for cleaning without disassembling anything else.

At the moment I'm looking at this combo:

Brass barrel https://www.bilbycnc.com.au/DisplayProd … rrel175xM6

Aluminium heater block kit with resistor and thermistor https://www.bilbycnc.com.au/DisplayProd … erBlockKit

0.34mm nozzle https://www.bilbycnc.com.au/DisplayProd … PtNozzle34

Apart from wiring up times four, as far as I can tell the brass barrel just needs to be cut down to the right length.

Thoughts?