Topic: Newly Installed E3D Problems

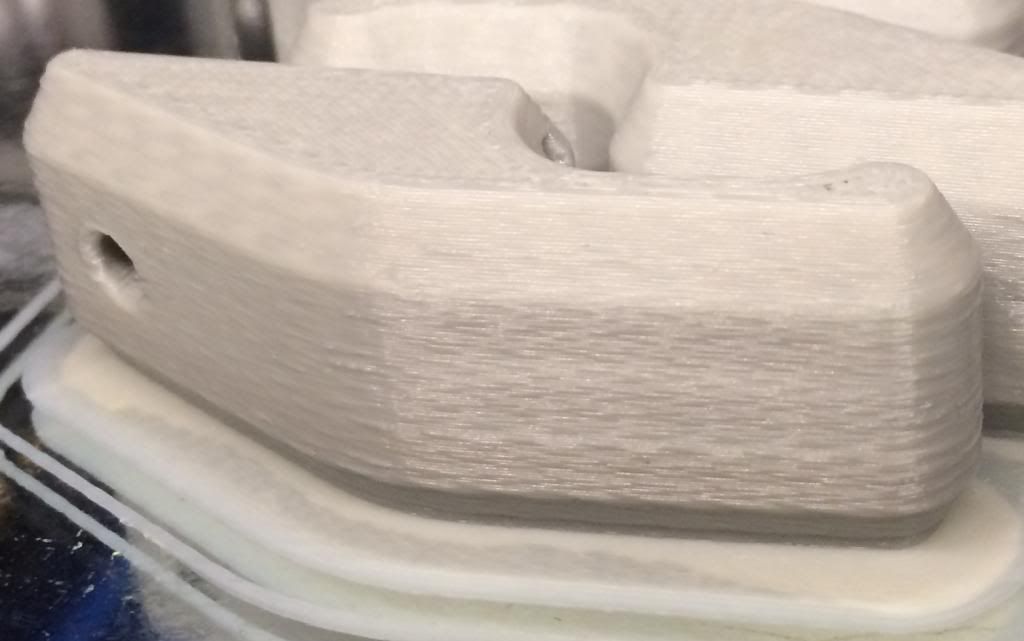

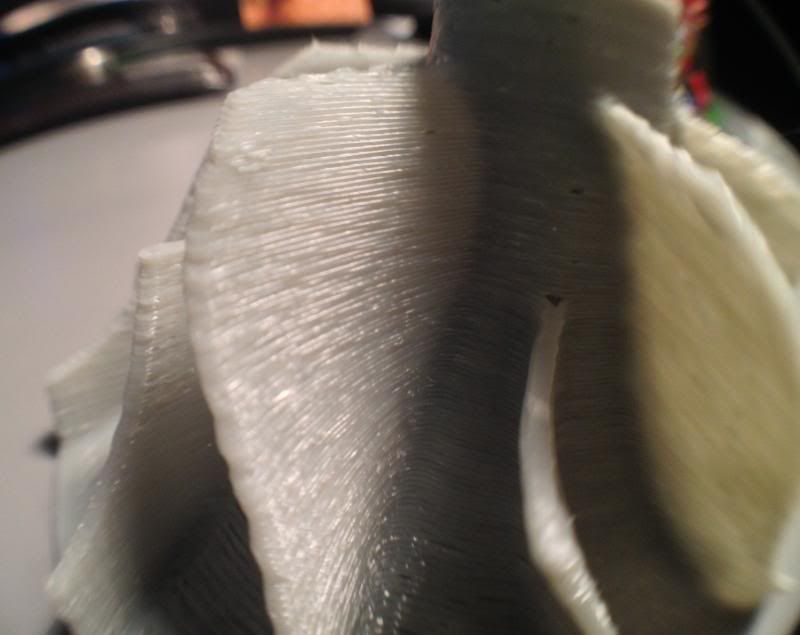

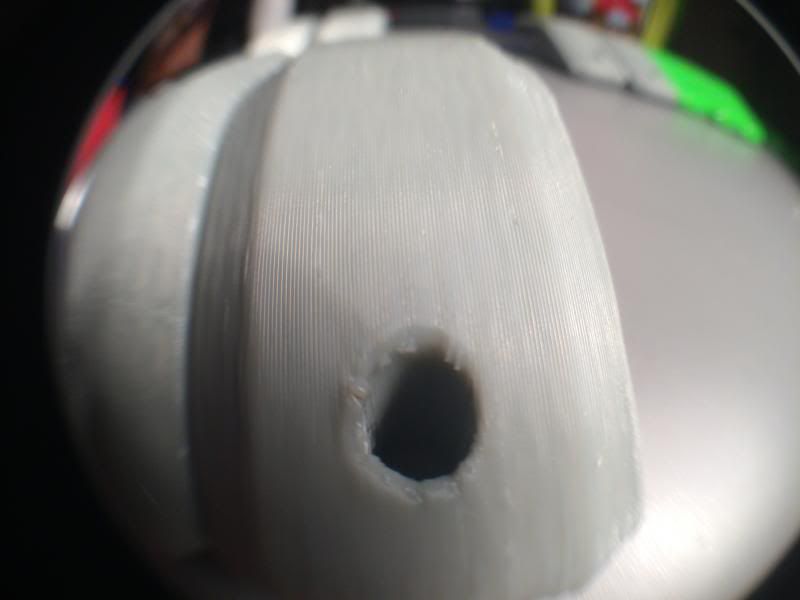

After installing an E3D hotend to my SD3, I started to experience a weird extrusion issue. Because of the nozzle size increase (from stock SD3 0.35mm to 0.4mm), I upped the extrusion width from 0.42mm to 0.48mm. I'm not sure if that is what caused this issue, or if it is something wrong with my extruder. It seems to have a pattern when printing a calibration piece with a flat wall, so I don't think that this is a random over extrusion issue (it has also been calibrated with a single wall print to be exactly 0.48mm wide). I have never adjusted my stepper drivers before, so I suppose it could be that. I honestly have no idea though. Has anyone experienced anything like this before? I'm getting tired of constantly fiddling with this thing to get it to simply print correctly. Any help would be greatly appreciated.

My printer has stock everything except for the E3D hotend.

I can take better pictures this afternoon if need be. Thank you all.