Re: RepRapDiscount "Bulldog XL" Geared Metal Extruder on a Solidoodle 3!

I tried bringing the existing mount into tinkercard, but their STL importer seems to bastardize it in spots. However, I think based on other examples I've seen online, I may be able to use the front lip to mount a servo and arm too. Ordered a few parts and hope to try something out over the next couple of weeks.

Just a tip I found the hard way. First print I did off the mount I had a lot of problems with the belt nut holders and the print having a gap due to the thin wall (so it broke when tensioning the belt). I printed out a second mount this weekend, and turned off "Detect thin walls" in Slic3r and printed that section perfectly. Live and learn.

I've not had that problem with the "Detect thin Walls" turned on. If you get me a picture of exactly where it broke I'd be happy to try and beef that section up.

3-SD3's & a Workbench all fully enclosed, RH-Slic3r Win7pro, E3D V6, Volcano & Cyclops Hot End

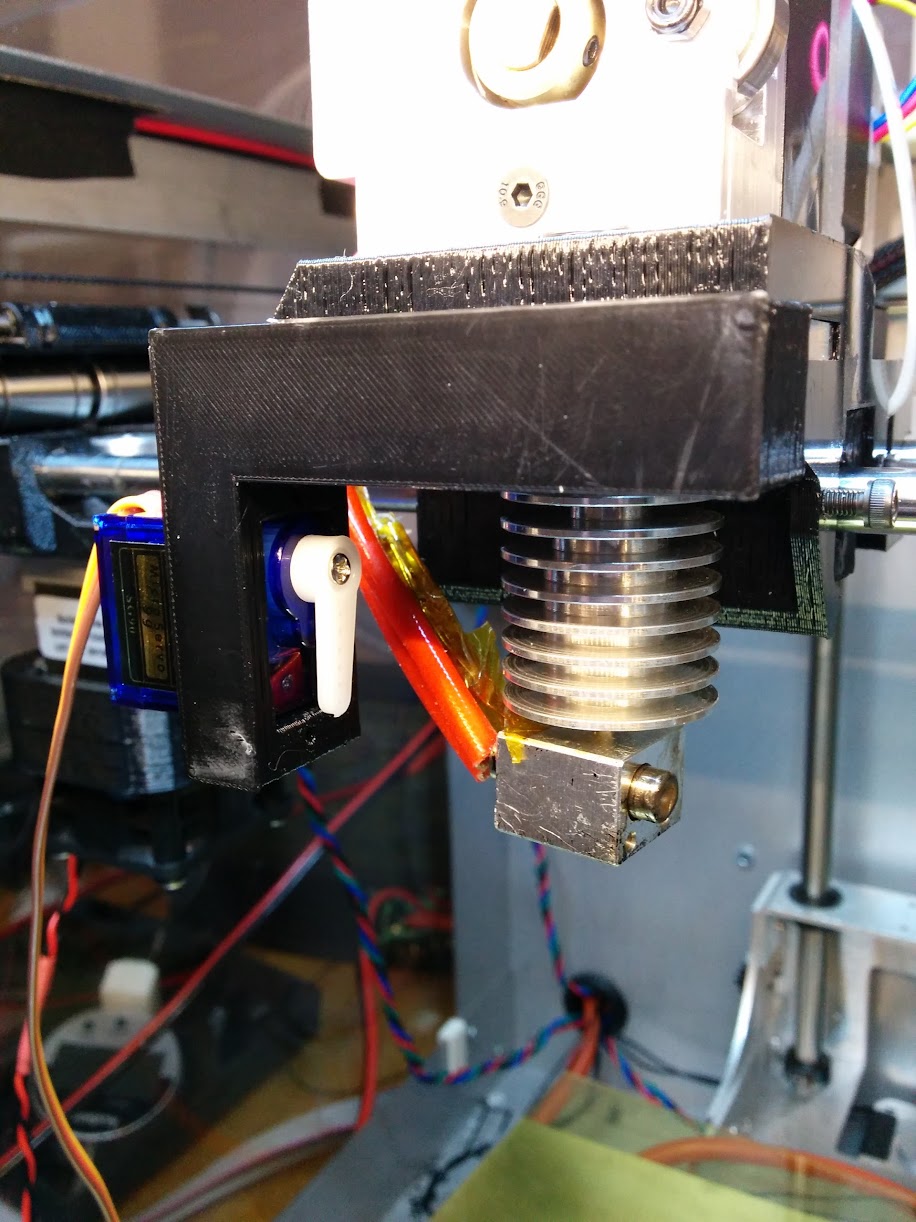

SSR/500W AC Heated Glass Bed, Linear bearings on SS rods. Direct Drive Y-axis, BulldogXL

Thanks to all for your contributions