Okies, I'll try to cover everything

Re the tiles thermal mass - this is relevant even during printing. If you drop something hot onto glass, all the surrounds will suddenly increase in temperature whilst simultaneously the extremities of the plate will be rapidly loosing temperature. Its these delta's in temperature that cause print stability issues. Ceramic tile, being just, bigger, will not experience these deltas to as greater degree.

Using tile is a greater mass/surface area than glass, consequently, yes, there is a *slight* increase in warm up time. In practice, the only place I saw it add a notable amount of time was the standard SD bed, which takes an eternity to heat up and soak anyway. I was able to print without problems waiting 15minutes with a covered bed vs 20minutes with the tile.. despite this, I still printed 'more', because I had far more successful prints. If you have a standard bed, dropping a dish-towel on the bed during heatup accelerates matters and the same remains true with a Tile. Using PCB or Qu-Bd beds, they have such an aggressive temp curve anyway, I saw next to no difference in practical application.

Also, you can remove objects much easier - the tiles not fragile  So I have found I can lift pieces right off once the bed <80°C... or knock them off with a sharp grabbing motion when the tile was still at temperature. Overall, less need to cool beds.

So I have found I can lift pieces right off once the bed <80°C... or knock them off with a sharp grabbing motion when the tile was still at temperature. Overall, less need to cool beds.

Glass used in those tests was 'regular' glass... Pyrex (meh, I'll use a trade name, less letters to type than Borosillicate  ) wont dramatically improve the thermal resistance et al, but it will make the glass surface stronger and less impervious to thermal failure.

) wont dramatically improve the thermal resistance et al, but it will make the glass surface stronger and less impervious to thermal failure.

You also, regardless of the bed, always want to provide time for thermal soaking... this means allowing the item to achieve equalibrium (to the extent it can) across its surface. Even without a ceramic tile, this is often forgotten. There is a BIG difference between printing the instant your bed says 90°C, and letting it 'soak' for 5 minutes...

Re the tile flatness, lets split it into two categories; 'top' and 'bottom'.

Top flatness - You will find most flat high-gloss glazes are pretty flat. I of course suggest spending some time to examine the tile stock on offer, as some will have raised ridges at one corner from where the glaze was laid down, but I have two that are flat across the top, however one of them has a tiny 'dollop' in the very corner, which gets buried beneath a clip anyway.

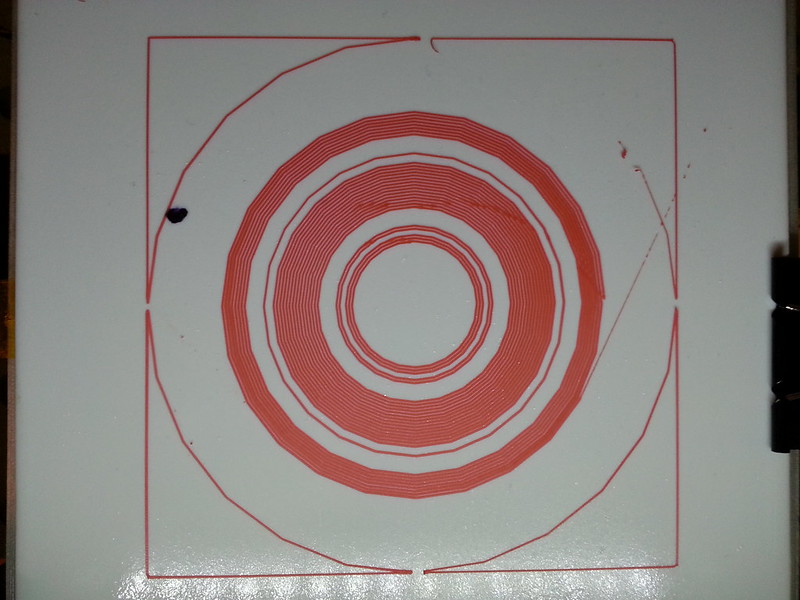

I'll take a pic of some single layer loops to demonstrate. Hand painted tiles of course are usually right out, because you'll have brush strokes and other texture detail. But commercial white high-gloss clear-glazed tiles will be pretty darn flat. And even if there is a slope across the face, it will be uniform, and thus, easily compensated for in bed levelling...

Bottom flatness - Yes, they do come in some different varieties.

If this was a Heatsink, where we were trying to measure things in terms of its Thermal Transmission and get some sexy high figure like 300°C/W, then yes, the bottom would become an issue as it would be degraded compared to what *could* be achieved. This is of course what the point of heatsink compound is when constructing a heatsink assembly on say a MOSFET or CPU. Heat doesn't transfer across air 'well', but it DOES transfer... which is more than enough given the clearances on the tiles I've been dealing with that have a 2-3mm recess . Even back on the 'stock' bed, it took still less 'additional' time versus the overall time in the first place... Anyway, remember the key to stable prints isn't a magical arbitrary value, but it is the *rate of change* and the *uniformity*... a Uniform bed at 80°C will print 'better' than one with hotspots and sharp fall off but reads 95°C right there at the thermistor location...

This is why one of the common suggestions on a standard bed is 'increase the temperature'.. as the ratio between the hotspots and the edges decreases... it still exists, but putting more power into the aluminum means it needs to either increase dissipation, or, it heats up and becomes more stable. If we ran the bed at 350°C, besides being half the melting point of aluminium, it would also be almost even across the whole plate as the power would overwhelm the Alu's ability to dissipate, and thus, will heat up and achieve equilibrium..

If in your particularly tiles instance it has big holes, or odd shapes.. then you could:

A) Live with it - I haven't found an issue in practice. Remember, you aren't chasing a specific °C here or super low thermal resistance (in fact, quite the opposite!  ) like you'd want on something designed to wick away and transfer heat out and away - like a heatsink

) like you'd want on something designed to wick away and transfer heat out and away - like a heatsink  ... you are chasing evenness and a slow-curve.

... you are chasing evenness and a slow-curve.

B) Lap it.. the underside is just hardened clay  Keep the tile wet, and file/sand it back.. just dont focus on one area too long..

Keep the tile wet, and file/sand it back.. just dont focus on one area too long..

C) Fill it... same principles apply as to a heatsink. Use silicon that sets, and even say some of the high-temp copper-laced gasket goop, and fill the back of the tile and then screed it flat.

D) Spend more and get a flat granite paving tile thats sealed. But these can be expensive. And heavy. But theres a reason they make 'pizza stones' from this stuff, and its not that dissimiliar to what we are trying to achieve (slow rates, even temps).

Personally.. I'm pretty happy with A.. but feel free to experiment with B, C or D. It comes back to that 'we aren't building a heatsink here' which is where grooves and depressions would definitely lower the performance curve and the heatsinks ability to function as the most efficent heatsink it could. As its just a lump of uniform warm stuff around various temp ranges, then it seems to work just fine.

Having said all that waffle... I should add - I don't claim to be an expert..