Re: Is it worth trying to keep my Solidoodle 2 going?

@n2ri

You can try filatruder.com for the hobgoblin. That's where I got mine. The owner is elmoret who is a forum member here.

For a drop in replacement heated bed, you can try: https://www.geeetech.com/mini-square-pc … p-877.html

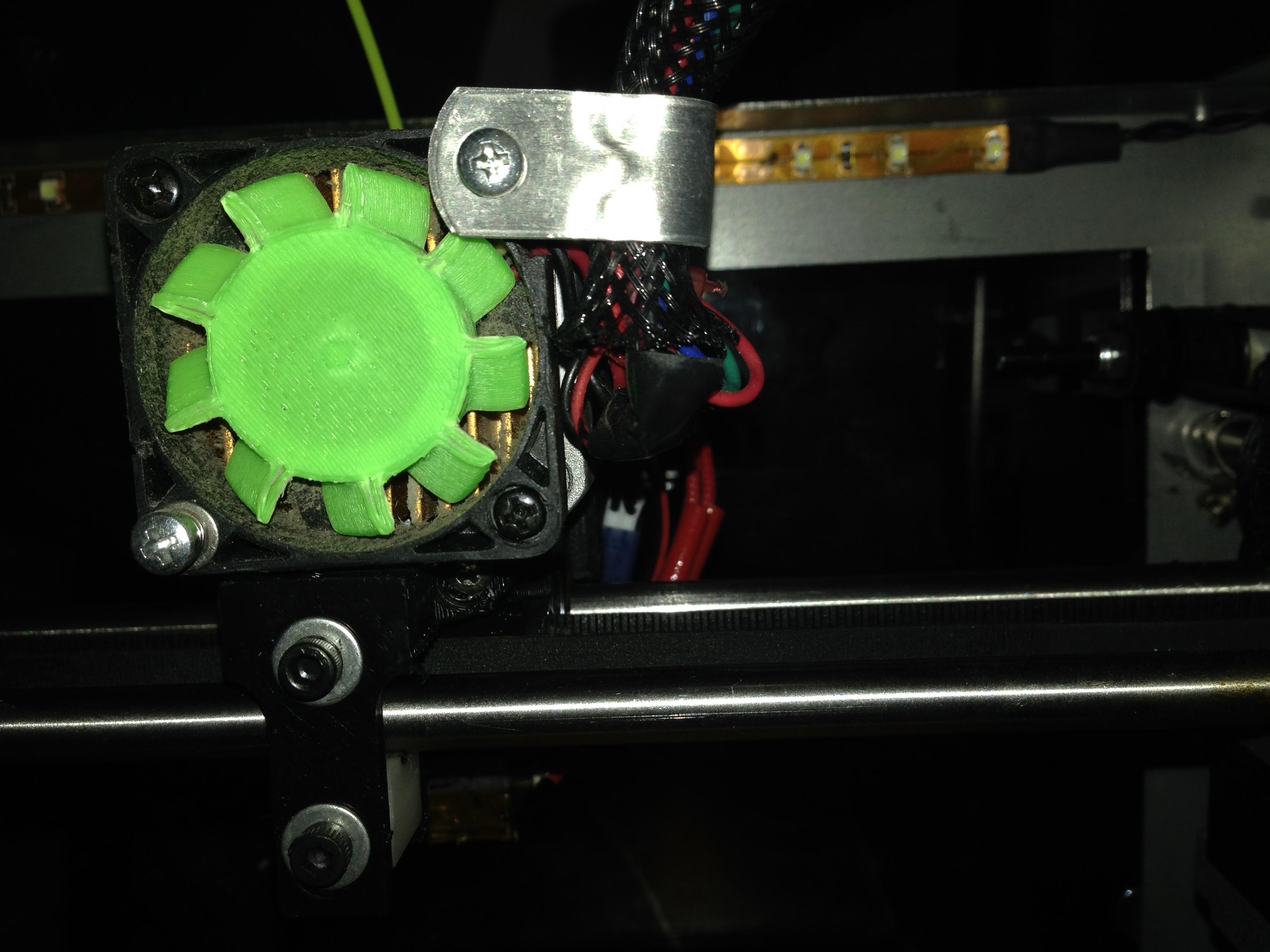

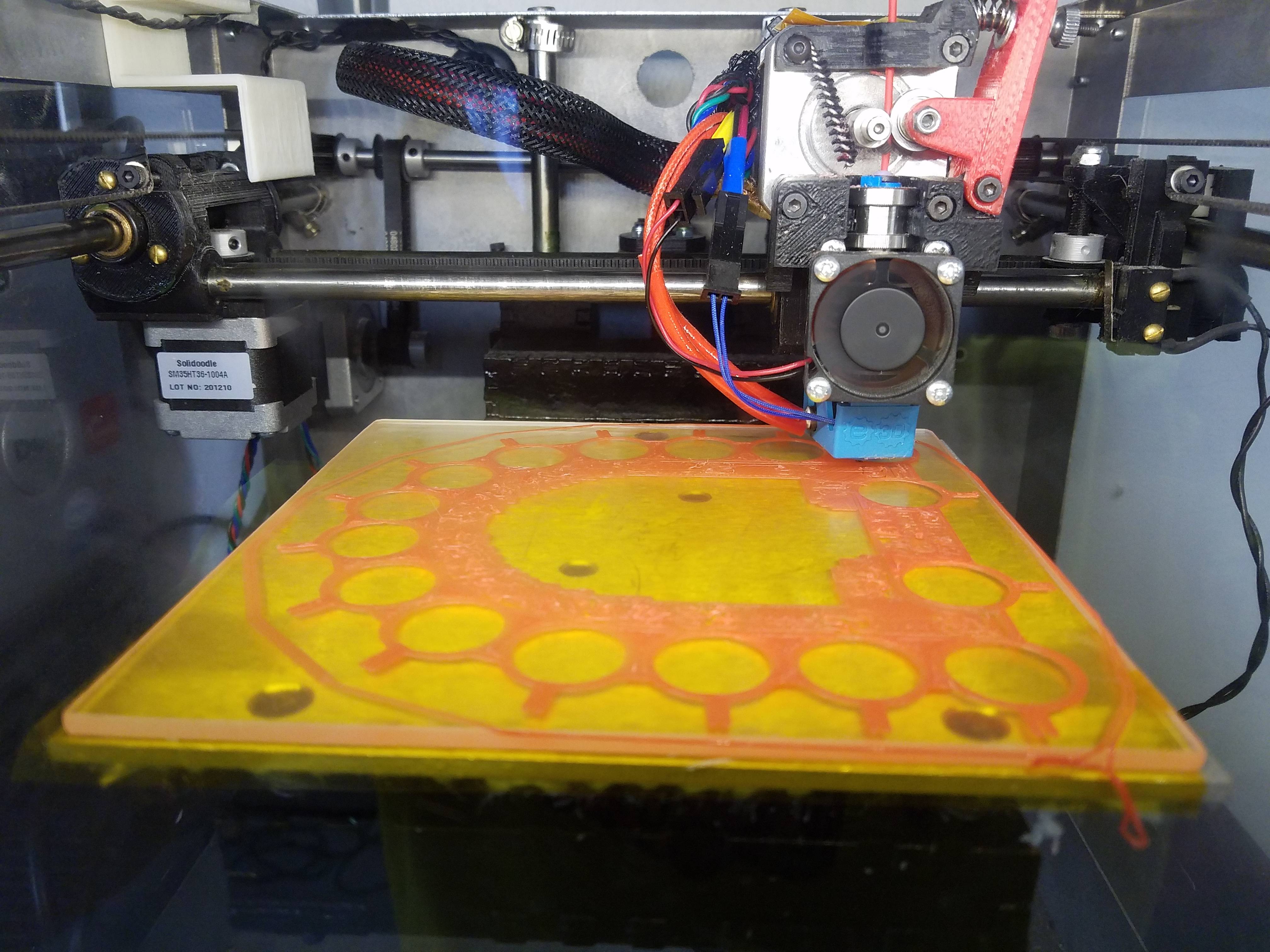

It is for the Geeetech MeCreator which is a SD2 knockoff. I've not actually tried it myself but I have the MeCreator and a rough measurment says it will fit. Also, some folks have reservations about the quality of Geeetech products so don't yell at me if you it doesn't work out. ![]()

Cheers.