Topic: Broken glass build plate. Has the OEM improved? Other suggestions?

I'm having ALL the famous problems with my new-old-stock Davinci 1.0.

I left a 7-8 hour print going last night and woke up to a perfectly formed print, with glass fused to the bottom and a shattered work plate. Pictures attached.

I've been reading around online for solutions, and all the conversations I'm seeing seem to be about 2 years old. I've looked at videos for removing the heater element and then replacing the glass with boro or tempered glass, but the element is already damaged due to the glass shards. It isn't coming off.

XYZ does appear to have replacement platforms available on their site for $60. (This was apparently a problem before, too, as they were always out of stock.) I don't mind spending $60, but I don't want to buy the same problem.

No idea why it even broke. I didn't try to remove the print early — it sat in the machine overnight, it was plenty cool. One of the contacts does look to be scorched, and had been that way for a couple of days.

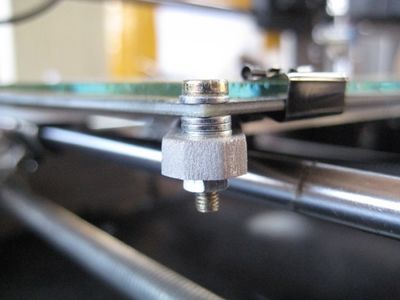

I have done no mods, other than replacing two of the (broken) bearing brackets, and yesterday I did replace the stock connector heating the extruder, which was sporadically not heating. I've used nothing but stock XYZ filament. Most of the time I haven't even used glue on the glass, as none of the prints I have managed to make have warped or failed to stick.

I'm starting to hate this entire thing, to be honest. I've had it, like, 3 weeks, and have spent more time repairing/researching repairs than using it.

SO! To the point(s).

1: Does anyone know if XYZ has improved the glass for the replacement bed? Is it going to be the same problem if I buy the OEM replacement?

2: Does anyone have any idea why it's breaking, or have suggestions for things I can do to the new one to avoid this in future? Tape? More religious application of glue? Avoidance of glue?

3: Does anyone know of any third-party solutions that may be an improvement, for the heater element plus the glass? I'm definitely going to need both.

Thanks again.

Hurrffff, this thing is exhausting. And I was so excited that this print is perfect, because it's my very first remix for a very specific purpose. It was exactly the right size and everything.