Okay, so I think I have to try to repair this before shelling out for a new printer.

This is the best link I've found so far on how to do it. http://tomhorsley.com/hardware/solidood … irect.html

What I want is a clear parts list. From the link, I see I need:

From Misumi.com

http://us.misumi-ec.com/

2 of parts number SFL686ZZ - the Flange Ball Bearings: http://us.misumi-ec.com/vona2/detail/11 … s2products

Question: Do I need 1, 2 or 4 of these? Am I mounting them in the frame, or do I mount them in the Y-Rod Support piece? If I mount them in the Y-Rod support piece, how do I ensure everything is aligned? Do I have to drill into the case to do this? Best way to do that? This is the most confusing part of the page for me.

1 of parts number MCOCG17-5-6 - the oldham clamp http://us.misumi-ec.com/vona2/detail/11 … s2products

Question: Do these clamps require extra screws, or are they built in? In one of the pictures on the tomhorsley site, he has these taped together. I'm guessing screws clamp down on the 5/6mm rods, then friction/pressure holds the clamp together?

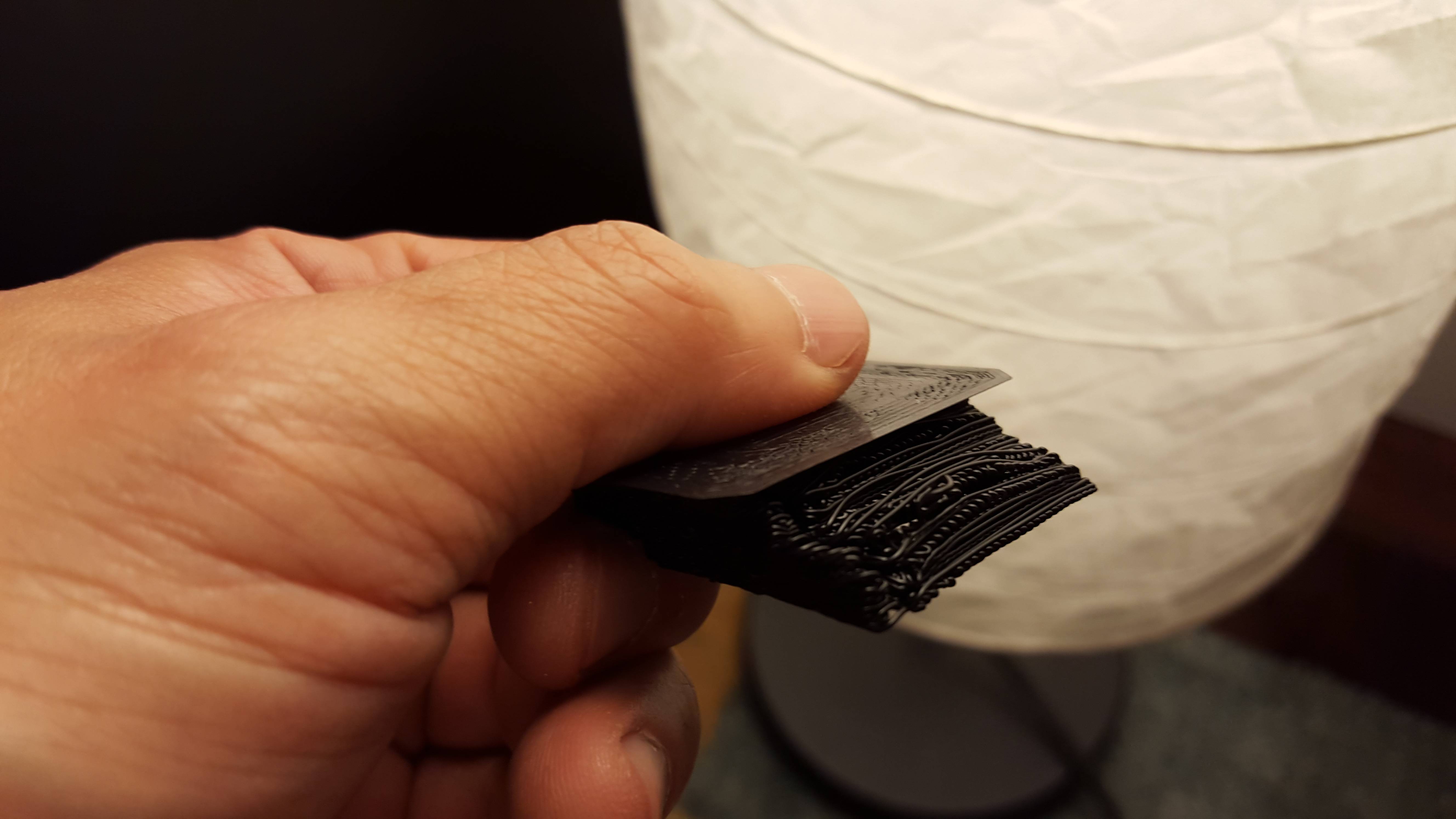

1 of parts number PSFJ6-340 - the drive shaft

http://us.misumi-ec.com/vona2/detail/11 … s2products

Question: On the tomhorsley site, he says that he got a 340mm length rod, but you can see from the pictures it sticks out by 3-4cm. I don't mind it sticking out a little, but less than that would be nice. Anyone have a better size estimate? 310mm?

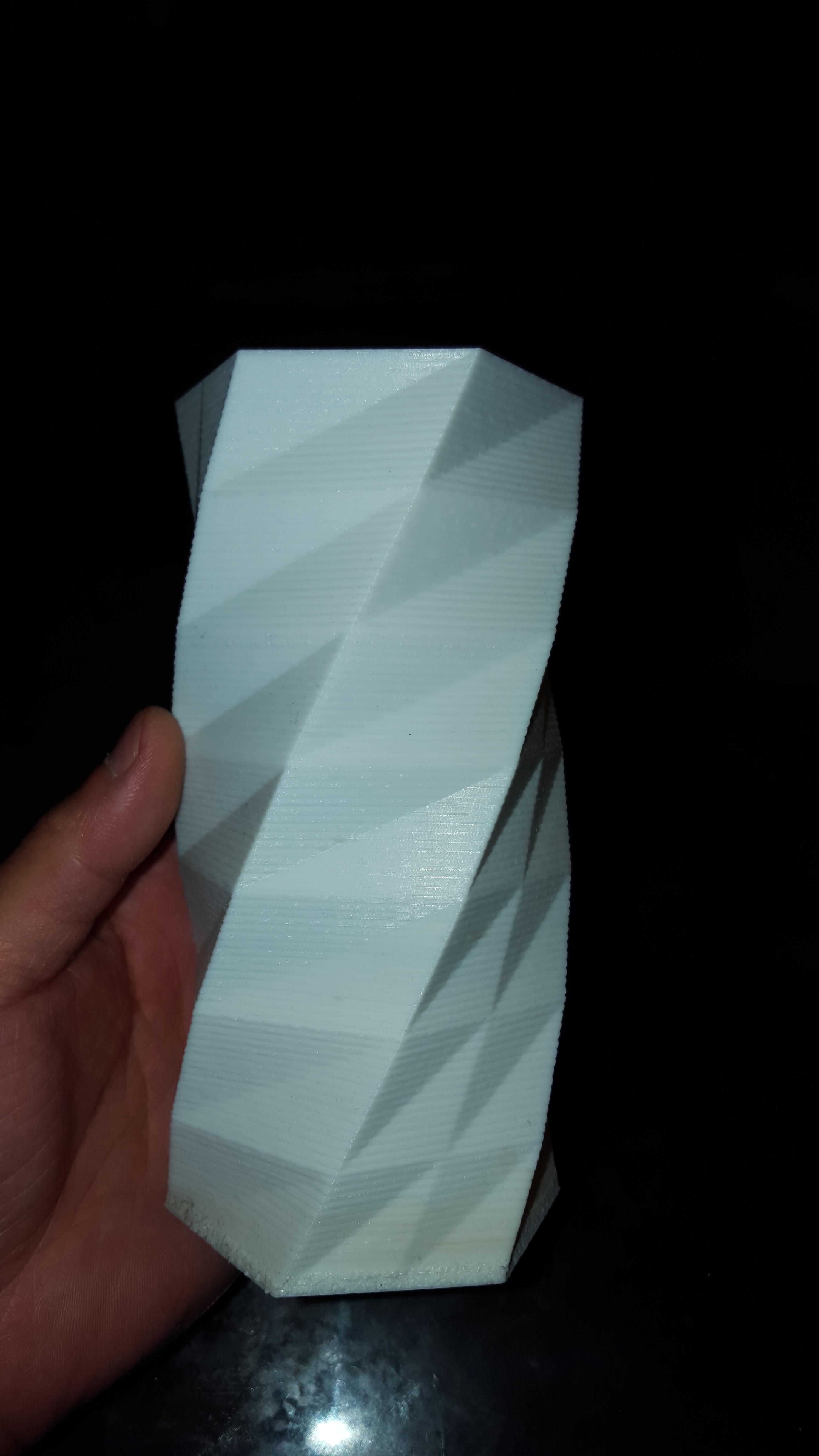

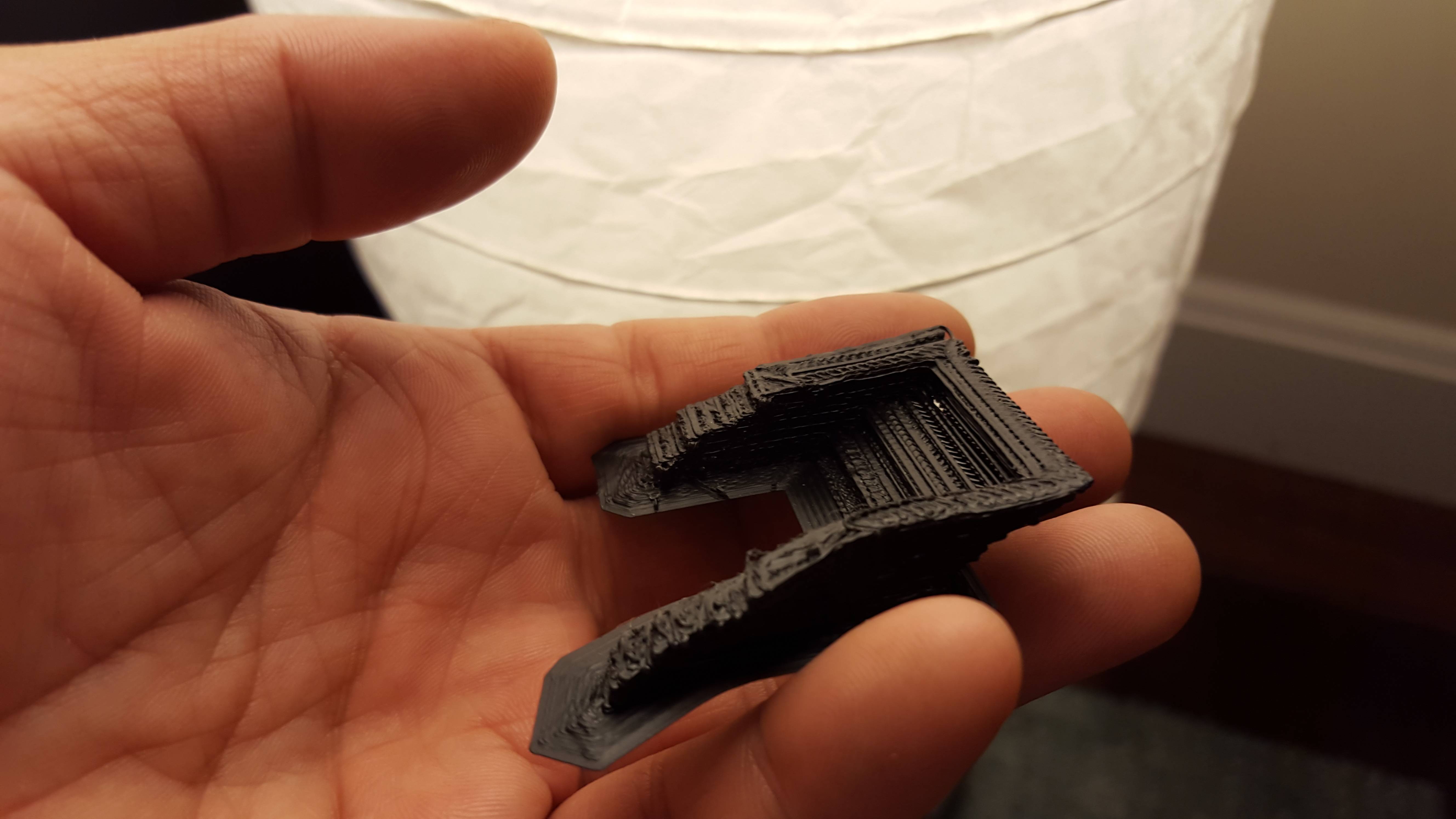

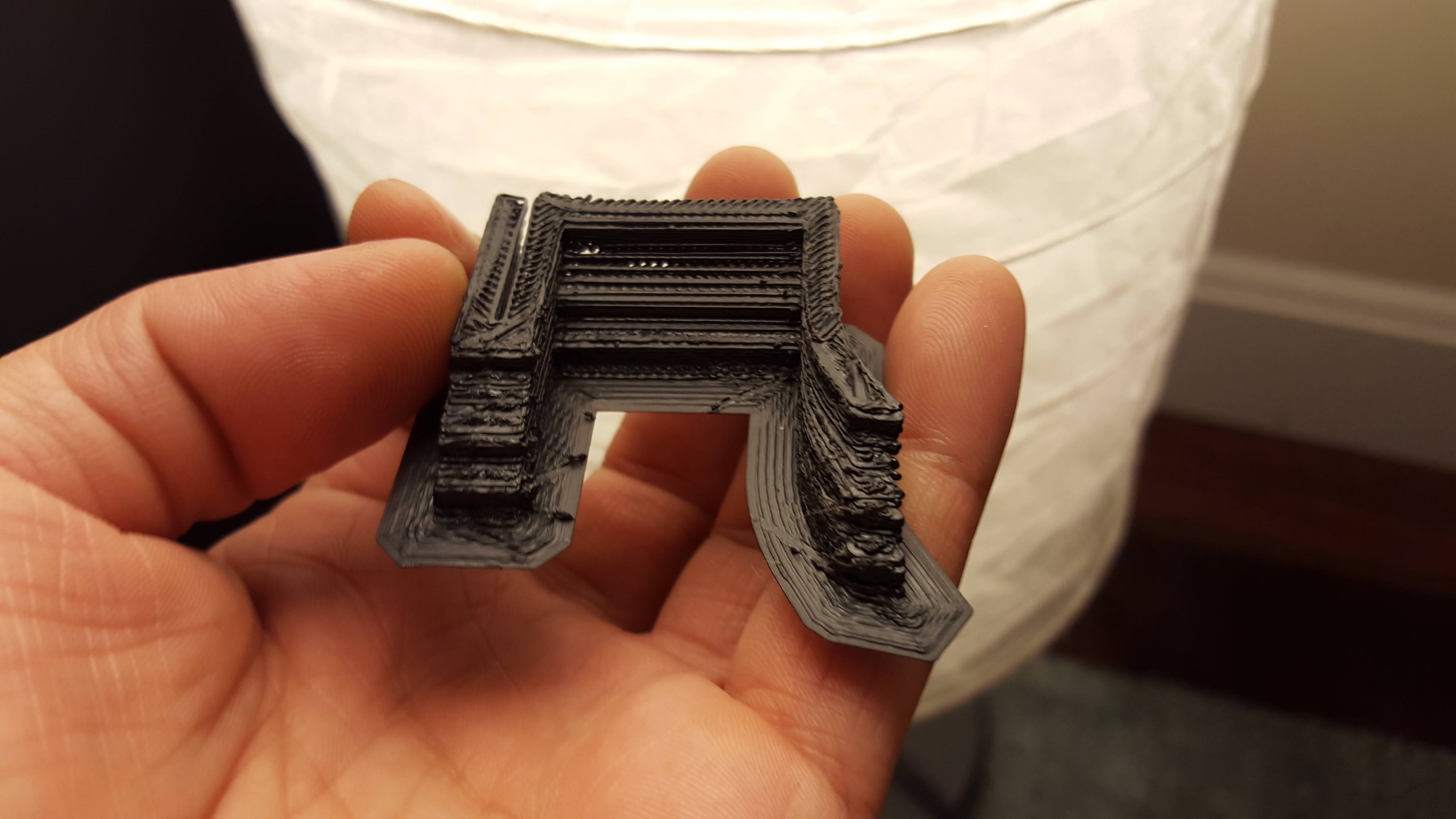

If someone is willing, I'll also need the mounts printed. I tried to print the one mount from last night, but the circles were not remotely close to circles. I don't mind paying a bit for someone's effort. PM me if you are interested in helping me.

I'm also not clear on all the screws/nuts/bolts I need. He mentions swapping out the 10mm with 20mm M3 bolts - would this work:

http://www.amazon.com/Yosoo-Button-Hexa … +m3+screws

I can see where you would screw the motor to the mount, and how you would screw the bottom half of the mount to the frame, but wouldn't the top half of the mount also need to be screwed to the frame? If so how?

As mentioned above, I'm not clear on whether I'm replacing the bushings completely or not. He mentiones sliding the new rod through the bushings being difficult, so I assume he didn't, but others in this thread have suggested replacing them with ball bearings. I'm guessing the ball bearing is just for the Y-Rod Support, which I don't know if I need or not.

I have a dremel and a old single speed drill. Are there any other tools or parts I'm missing for this project? Usually my work stops at the software side of things, so I'm a bit newish to doing hardware mods like this.

If I can do this project without drilling new holes in the case, that would be great, as that is what I'm least confident about. If that means doing part of the project (just mounting the Y-Direct, but not having a Y-Support), maybe that's the way to go? But if the ball bearings help that much, maybe it is worth doing?

Sorry for all the questions - just trying to make sure I have all the parts and know what I'm doing before firing the gun on this project.