Topic: How to forget about circle problems for ever....

So I know people occasionally seem to get bogged down about circles, and getting them right. There is often some jiggling and fidgeting around with everything repeatedly and often a lot of concern about having belt tension even.

Belt tension is very important for the OEM carriages, as they have delrin/acetal blocks that need to slide pretty evenly with the bronzed bushings to ensure the whole arrangement.. well.. keeps sliding ![]()

There is one place on the Solidoodle Belt Tension *does* directly effect circles on a OEM machine.. Its the continous belt connecting the Y-motor to the link rod (vertical belt in the pic below). There is a tendency to want to crank this motor tight to eliminate backlash, however this has a counter effect - it causes the 6mm link-rod to deflect due to the tension on the loop belt and even a small deflection will result in uneven timing between the axis and elongated (or contracted) geometry in the print as a result.

But fear not! There is a simple "do this once and forget about circles and pretty much belt tension forever" fix!

I've been running this mod since April when Smitty505000 posted it into his thread about all-bearing conversion : http://www.soliforum.com/topic/2361/all … onversion/ . In there you will find this post which contains an STL. Download this and print it. While printing, go to ebay, and purchase a batch of 6x13x5 flanged bearings. Upon recieving the bearings, insert them into the pillow block, detach one end of the link rod after loosening the grub screws on the pulleys, remove a pulley and slide on the pillow block. Replace pulley, and then locate the pillow block and attach to case rear. Snick everything up time and your done. For good. Seriously.

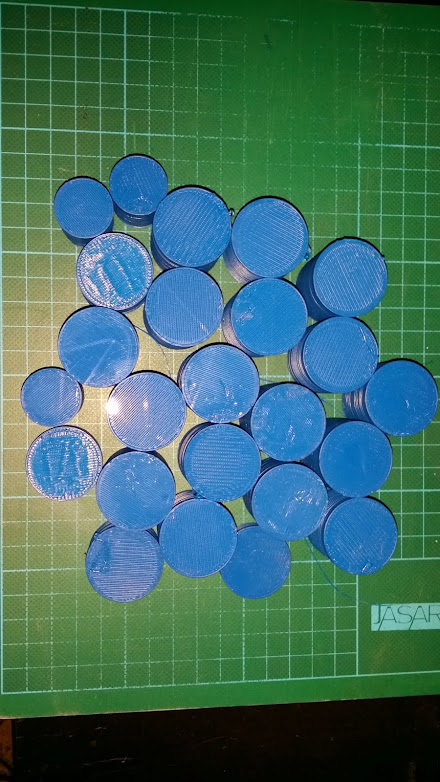

You can crank your Y-Motor as tight as you can get without distorting the frame, and can print with belt tension thats as uneven as this: (note the now long unused 'coin calibrator' compliments of IanJohnson):

Left

Right

And get perfect circles again and again - this is the weekends test prints of trying out some things elsewhere on the printer:

I havent adjusted belts since I installed my bearings for the lawsy carriages...

If you like this mod as much as I do - buy Smitty505000 a virtual beer for making the STL for us! ![]()