Sorry for Necro, but this describes my precise problem except with a new twist. It seems to happen only when the printer is "cold". When i do a new print after sitting for a day or so homing almost always binds and i get humming/grinding and Y doesn't move.

When i disable the motor, i can move it back and forth without any problems. after jogging it back and forth using manual controls a few times, it seems to work. (mostly? I was getting some x/y skew in one print i was assuming was because of overextrusion snags.. maybe it was this) I was hoping the motor was dying ..or maybe the driver. Something i could drop in and forget about for a little while.

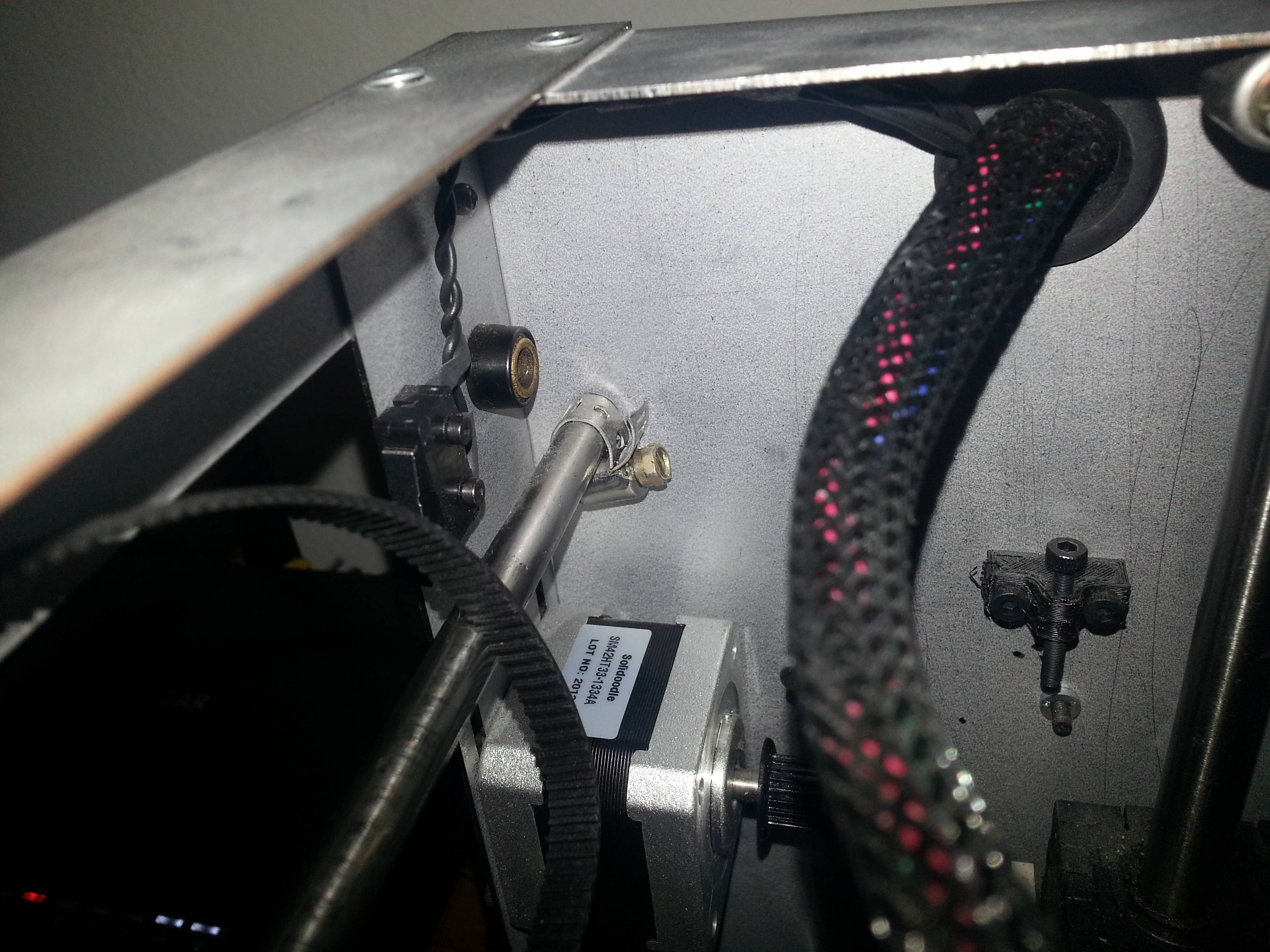

All my brackets seem fine. the belts have same tension they always have.

I finally got confident enough with my calibration etc to attempt a real project (3dpburner) and this shows up ..sigh. Anything you guys can suggest before i buckle down and rebuild my Y-axis?

I assume 3 in 1 oil will work to lube the bushings (forward and back). I don't think i saw anyone mention what i should lube with in the thread. Sorry if i missed it. Also i assume i would need to remove one of the X rods and the y carriage to do anything about the linear bearings?

Edit:. I now hate solidoodle. I went and disassembled my y axis and re greased everything. Still have y shifts. Went to take out the front pullys to see if there was hidden damage and noticed they were attached with red threadlocker. Unfortunately this was after I stripped the head. Looks like I have to destroy the brackets.to get it off. Why use threadlocker on such a delicate part... I know from experience that threadlocker turns abs into dust. I can't even print rep!acement brackets.

So.. now my choice seems to be give up and buy another printer or buy some more brackets from someone and break out the blowtorch with no guarantee it will fix anything.

So much for my laser engraver project...