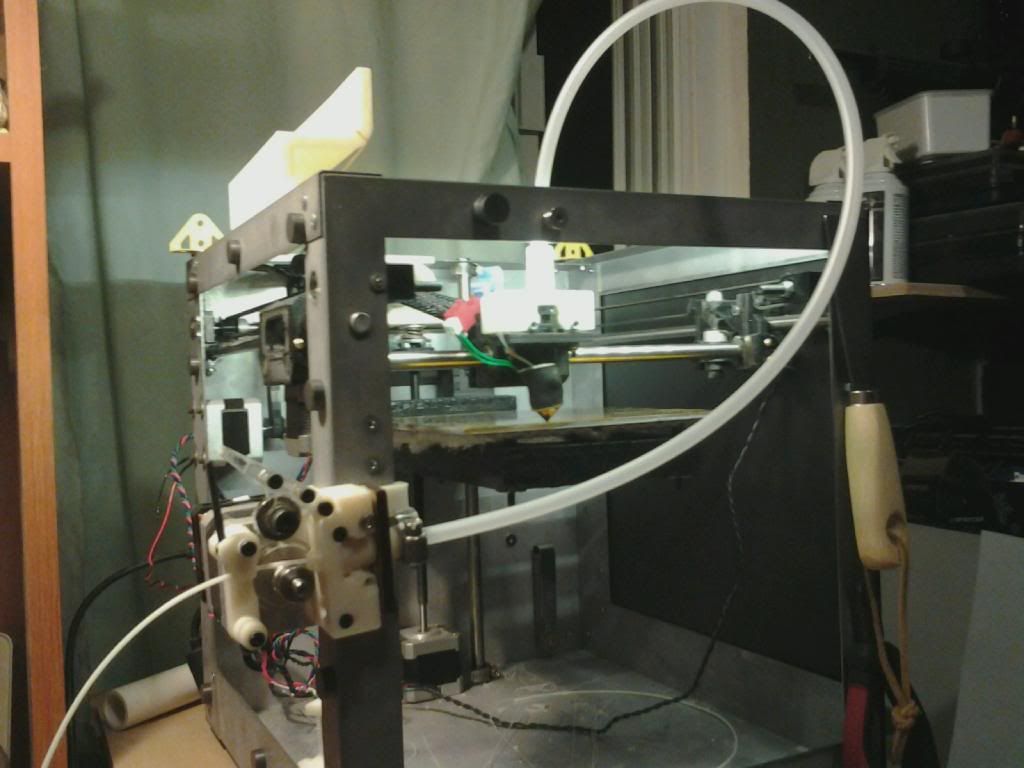

Topic: Bowden attempt

Had some down time to muck around with the printer, and figured on the next clog I would try to cobble something up using much of the supplied parts from other solidoodlers. I don't know much about these setups, but figured any decrease in weight on the printer head would be good to decrease the over-shoot and flex as mentioned by IanJohnson in the speed improvement thread here http://www.soliforum.com/topic/495/speed-improvement/ .

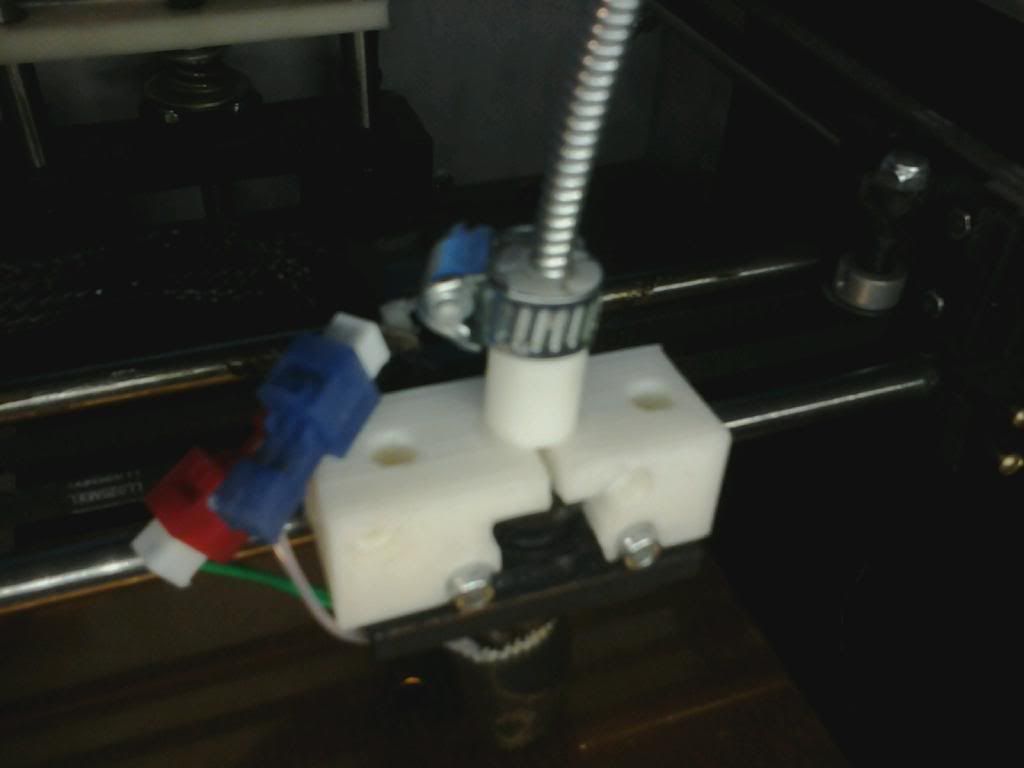

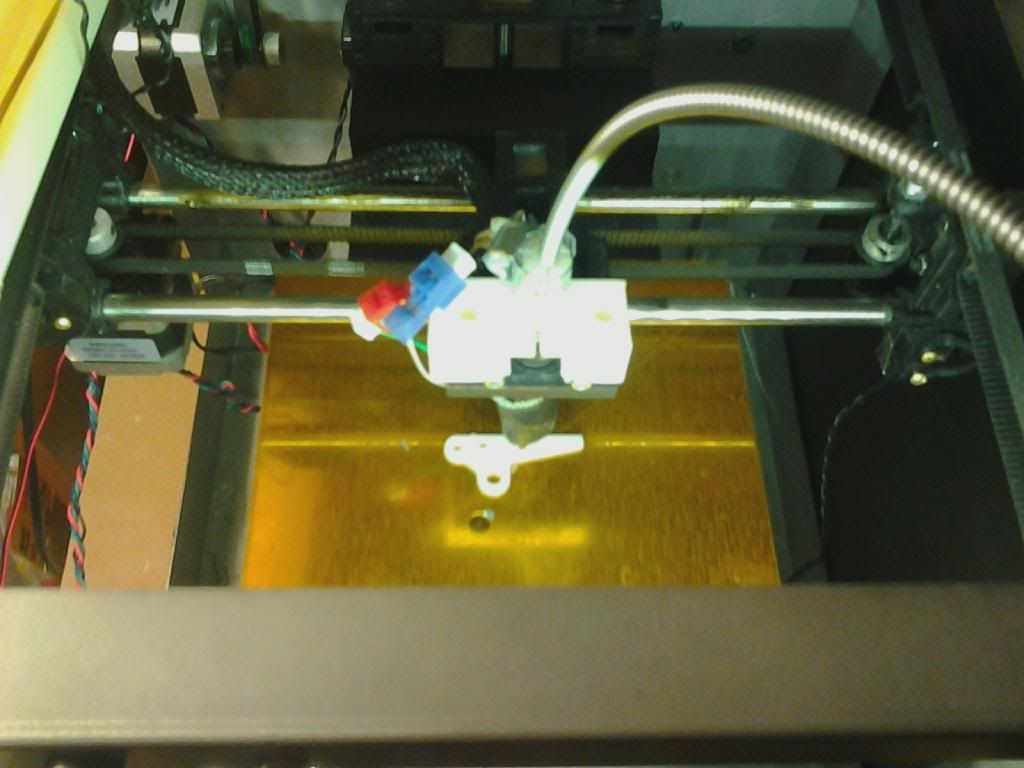

I was surprised to find that the extruder motor is only secured to the platform through the use of the extruder parts and 2 long bolts. So I wouldn't be surprised if the nozzle is being tilted forward and back during quick movements.

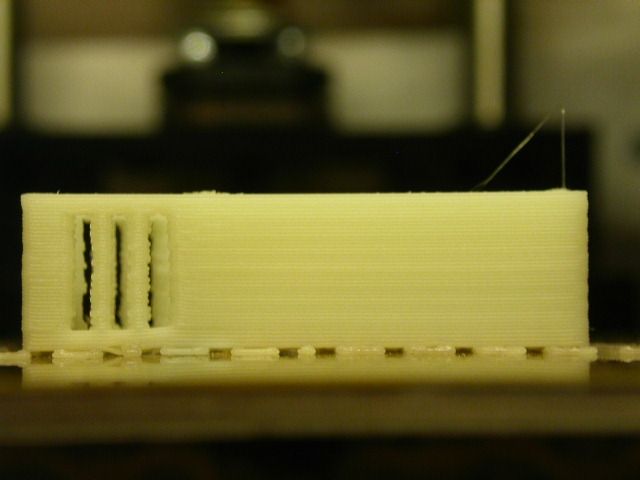

The tube I'm using is 1/4" as it was the only size I had handy, but it seems like I will need to get something smaller as the filament tends to compress and bind up in the tube. The extruder motor didn't seem to have any problem though pushing the filament a longer way to the extruder nozzle.

Figured I would post now even though it's not done just to get some talk going. Would be interesting to hear or see other peoples attempts, and maybe just get a thread going to increase the knowledge for myself and others.

Do you think there's value to the mod, or would it be better to just secure the extruder motor more fully to the rest of the printer head assembly?