Thanks elmoret, that doesn't sound too bad as far as changing the steps. I suppose those are all avenues to check out if this doesn't work out. I'll have to order the PTFE tube at some point; just waiting till I have other items that need ordering. I'll try shortening the tube next now since I moved the motor up higher and don't need as long of a tube now.

(Edit Update)

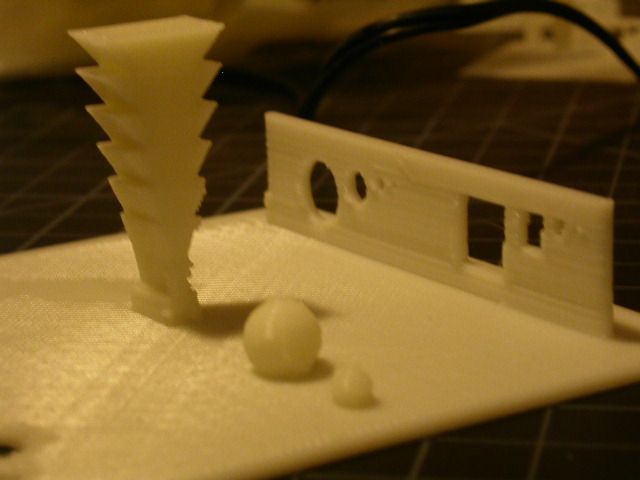

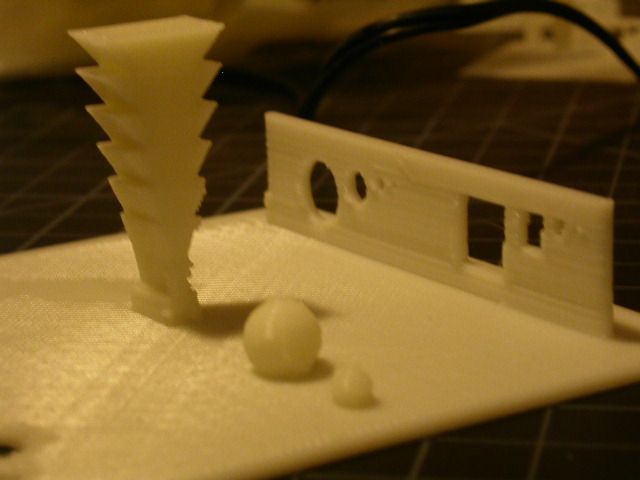

Well I was hoping to figure out what settings needed to be set so that I could just reuse the same settings for most prints, but it seems like whenever I get one print to work well those settings won't work for a different print, (I think I'm getting closer though to finding a good general set of settings for my setup though). I figured I would just go ahead a post some pics though even though I don't have it totally refined yet. I did manage to get the extruder to stop skipping so much on me. Seems that maybe with the metal tube I'm using that the 180 degree bend was too much. I moved the extruder so that the bend is more at 90 degrees now which seems to have helped quite a bit. I imagine once I get around to switching to a Teflon tube everything should work without any problems.

I did have to set the trimpot for the extruder up to .5. I had it up to .9 at one point but then the motor was getting really hot and then the printer would stop for a second or so then start again. I have also upped my temps to run the nozzle a little hotter than normal. Using the retraction has helped a lot as well with relieving some pressure in the nozzle which I think was also causing the motor skipping. I think I may have had the z-offset set too close to the nozzle as well which I have also changed to be more closer to the proper .3 distance. I had always had it set closer as the bed had low points and I would have issues with parts not sticking, but I also put a glass sheet on there now so the .3 distance is working good. I also mounted a secondary heat sink and fan to the extruder motor as precaution and has been keeping it nice and cool.

All in all, I see no reason to not add a bowden tube as everything seems to be mechanically tweakable to make it work with out needing to change anything in software/firmware stuff which was my intention with this project. (Not sure if changing skeinforge settings counts as software changes as I am not entirely sure what entails as software change, but I figure skeinforge settings are a normal thing to mess with even for novices like me).

Can't wait to see some of the more purpose designed parts some of you will come up with for your own setups. Mine was mostly cobbled together using parts you guys posted and things I had around the house as evident by the clamp I used to mount my extruder onto a mast for better positioning.

The filament holder in the below pic was also done using this bowden setup.