Re: FilaWinder Documentation

Why not get a relay that will run on the voltage the motor is running on?

They go as low as 3 volts? Or use a MOSFET/Transistor to in place of the relay and use the signal from the motor to run the gate of the transistor?

You also need to make sure you have a snubbing diode across the relays coil. If not you can damage things. When the coil of a relay is de-energized is generates a back EMF that can be several hundred to several thousand volts depending on the operating voltage.

You could also try a DC solid state relay.

Just to make sure, you are also using the buttons and knob correctly I sassume?

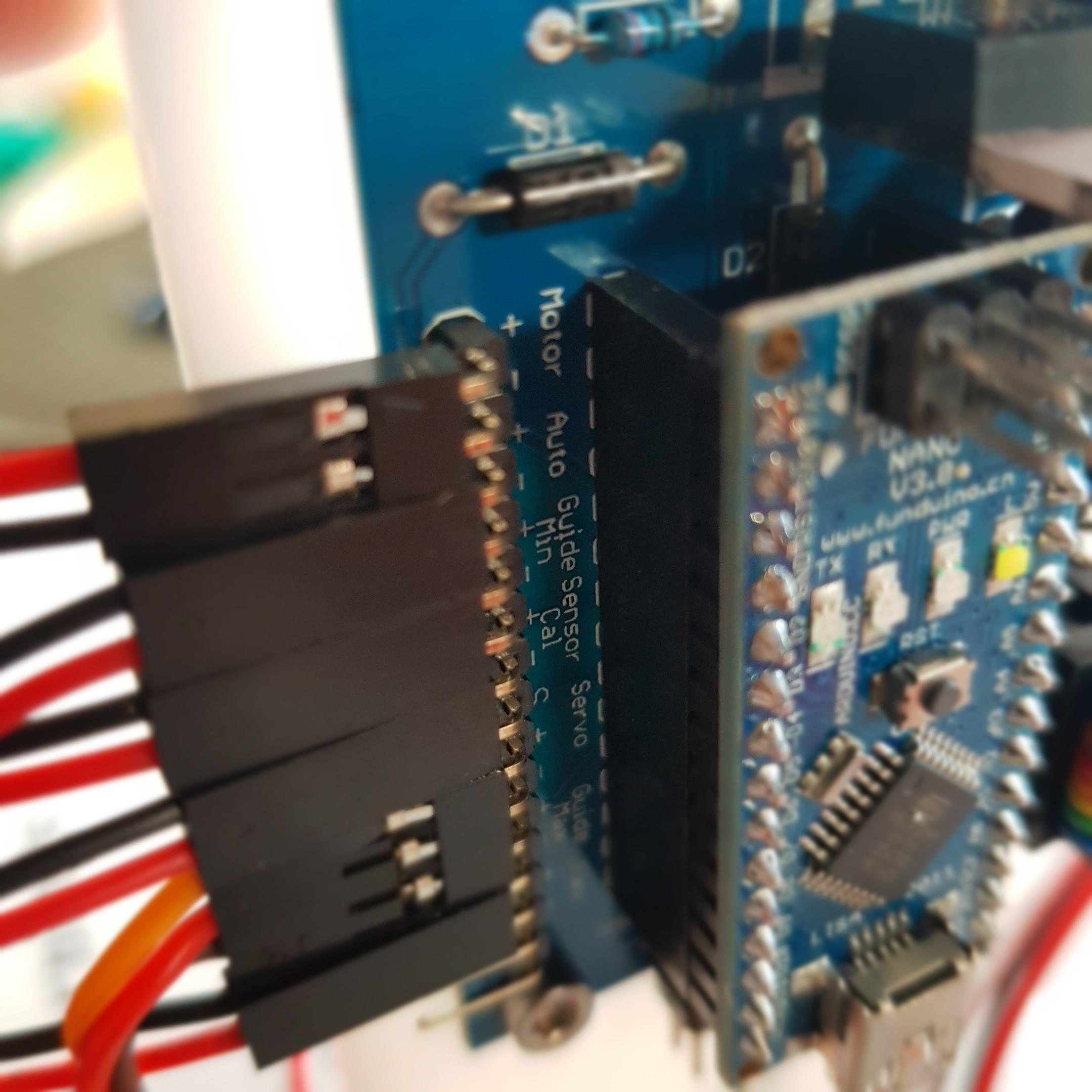

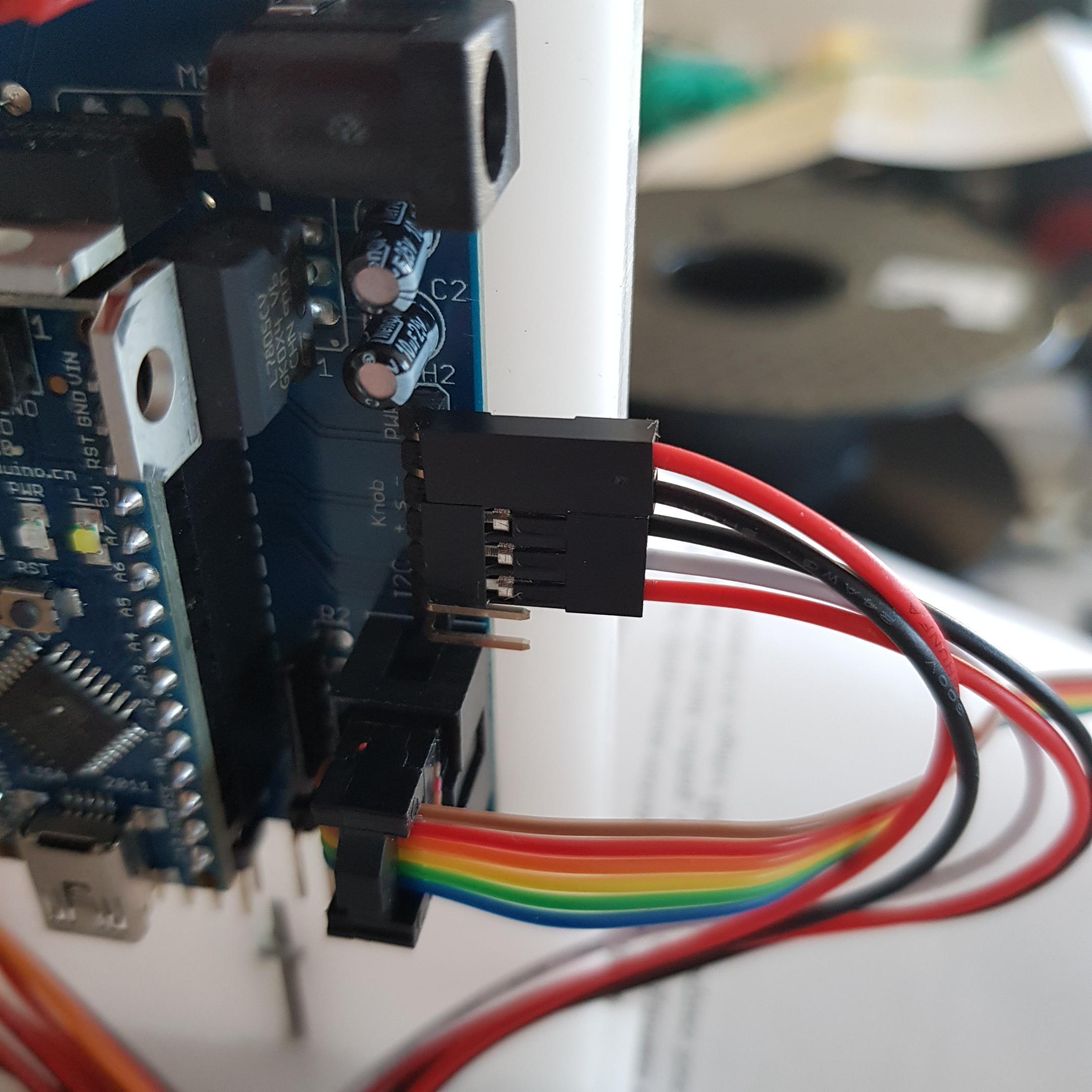

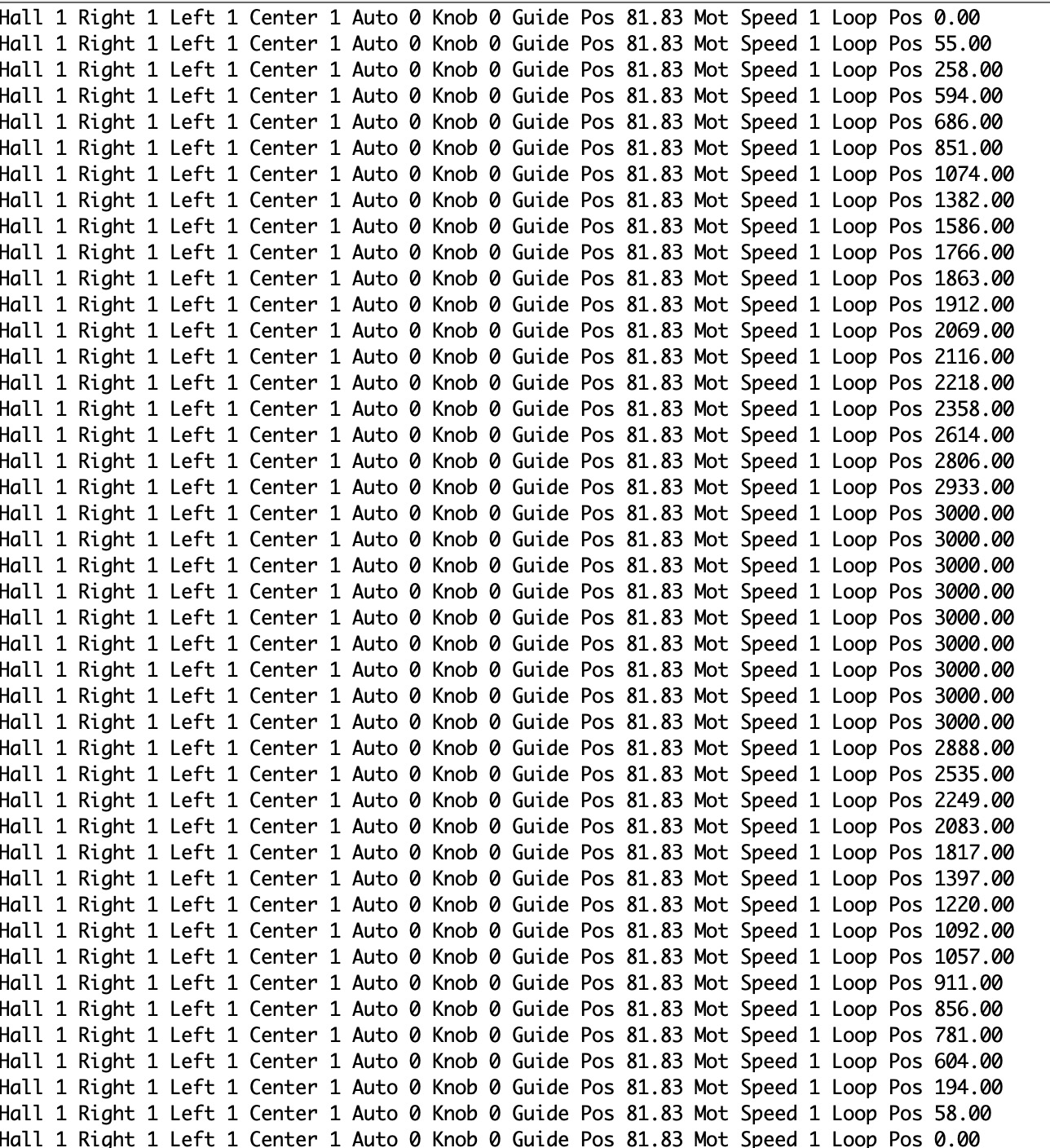

There is a switch to change between auto mode, (speed controlled by the sensors), and manual mode (speed controlled by the knob). When holding down the left button, the knob will move the guide to position it at its left limit, and the right button will do the same for the right limit.

While in manual mode the middle button puts the sensors in a calibration routine for 5 seconds. During calibration pass a piece of filament back and forth across the sensor, and it will record the values that let it detect when the shadow is present.

While the winder is running in Auto mode, holding the middle button will let you use the knob to set the current position of the guide, and whichever direction it traveled to get to that point is the direction it will continue as the spool turns.

Anycubic 4MAX best $225 ever invested.

Voxelabs Proxima SLA. 6 inch 2k Mono LCD.

Anycubic Predator, massive Delta machine. 450 x 370 print envelope.