Topic: Confirm Solidoodle Model??

I have a Solidoodle, but am not sure anymore which model it is. I am thinking it is 2, but not with the larger frame. Does anyone know how I can measure it and determine which one it is?

You are not logged in. Please login or register.

SoliForum - 3D Printing Community → Solidoodle Discussion → Confirm Solidoodle Model??

I have a Solidoodle, but am not sure anymore which model it is. I am thinking it is 2, but not with the larger frame. Does anyone know how I can measure it and determine which one it is?

How big is the print bed?

If it's around 150mm or 6in it's a SD2, if it's around 200mm or 8in it's a SD3.

Print bed is 6" by 6", but some models have larger frame/cube?

Print bed is 6" by 6", but some models have larger frame/cube?

yes the model 3/4 has a bit larger frame to accommodate the larger bed . the 3 is a basic open frame design the 4 has an enclosure.

Has anyone written down the specs of the Solidoodles to compare to machines that are currently made? I want to make sure my next machine is a complete improvement.

Not sure what you define as complete improvement.

If you are considering every feature improved not likely to happen.

My first machine is a SD4 I found it needed a lot of tweaking out of the box.

My latest machine is a monoprice Ultimate maker.

In most ways I would say the MP is a superior machine but not in every way . the MP was made in china the sd made in USA.

the adjustable z stop the mp a single screw you need a hex key to adjust. the sd an easily accessible knob.

the mp has the features for an enclosure the sd came with one standard.

Know of any machines with with internal ventilation? Like a separate container where the air gets blown into and a filter so you can print without much worry about breathing it in?

Know of any machines with with internal ventilation? Like a separate container where the air gets blown into and a filter so you can print without much worry about breathing it in?

As long as you are not burning the material the components released are relatively harmless. The only ones that might be of real concern are when you get into nylons.

If you want a fully enclosed 3d printer they are available but IMHO a bit pricey .

the Up mini and the up mini 2 are available from tier time or other internet vendors

Here is a link to the latest mini model

https://store.tiertime.com/collections/ … -mini-2-es

Current msrp $699 this is for a 4.75 x 4.75 build volume machine

This comes with a HEPA filter and a carbon filter a door safety switch and a filament can that protect from moisture.

https://www.tiertime.com/up-box-plus/

This one has a 205 mm square print bed aprox 8 x 8 inch a built in spool hold and all the bells and whistles of the mini model.

Current MSRP $1899

These printer have a good reputation

If you want one on these please do your research. prices and features vary depending on exact model. watch several reviews on you tube. This is information not a recommendation for or against this product.

That being said I know of no one on this forum that has a printer of this type ((Fully enclosed filtered system). Most of us here have several printers may are in common living spaces a shop off the kitchen , dinning room , living room or bedroom.

And there are no know health issues from these printers. I stick pretty much to pla. I have printed a little in PET.

Know of any machines with with internal ventilation? Like a separate container where the air gets blown into and a filter so you can print without much worry about breathing it in?

Yes these are availble as well but cost as much as a 3d printer.

https://www.printedsolid.com/collection … 8337090572

Again this is your choice there are commercially available enclosures and filtration systems and plenty of the right kind of filter to build your own. Again do your homework.

I want to consider all variables. Quality of heat bed, speed of print, accuracy, enclosure, potential water soluable support material, multicolor prints, layer height minimums, line thickness minimums, and of course build volume maximum. Price is less of a concern next time around. Machines have improved quite a bit since SD? Like 3 times faster for example?

They have. I paid about the same for my last printer vs the sd 4

the mp ultimate maker has a ball screw so layer thickness can be controlled.

as far as line thickness min that is nozzle dependent just make sure you can purchase aftermarket nozzles that meet your needs.

Print volume bigger is not necessarily better. I would consider 8" cube to be normal size. 12" is nice if you need the volume but take a long time to print something that large.For long tall prints the delta are an option.

As far as multiple material printers I would look at the mosaic palette . it can be used with almost any printer on the market.

I want to consider all variables. Quality of heat bed, speed of print, accuracy, enclosure, potential water soluable support material, multicolor prints, layer height minimums, line thickness minimums, and of course build volume maximum. Price is less of a concern next time around. Machines have improved quite a bit since SD? Like 3 times faster for example?

Speed is not the end all / be all of 3d printing. the faster you run, the more quality of print will suffer.

I run two Solidoodle 4s and get VERY good quality from them, but then again, I took the time to make a few modifications (that are readily available to any one that wants to do them) and took the time to learn how to properly calibrate them and use my chosen slicing software to its fullest ability.

In stock form, the 4 is basically the same as the 2 & 3, aside from the full enclosure. The 2 & 3 can easily be enclosed if that is what you desire.

I have also built 3 vastly different kit printers - a prusa style, a kossel/delta style, and a large format with a 300x300x~450mm build volume. All 3 were successfully built, calibrated and produce quality prints. The most expensive of the bunch was the large format, and even it was under $500 USD. So it is not about cost, either.

Pretty much any 3d printer on the market - regardless of price - is going to have its weak points. be it speed, build volume, being locked in to proprietary consumables, or something else.

Learning to make the most of what you have will get you a lot further than throwing money at another printer will.

As for the filtration thing.. not really necessary for most common filaments. I have COPD, and print with ABS with no problems, sitting an arms length away from the printers. The smell might bother some people, but particulates? No. Over-hyped nonissue.

going back to the speed thing.. i run my SD4s at 40mm/s print speeds - yes, they can go faster, but quality suffers.

the Kossel typically runs at about 60mm/s and the large format does well at about 100mm/s print speeds. I sold the Prusa style one long ago - did not like the motion setup.. but it typically ran at 40mm/s also.

I have one machine that is capable of much faster speeds - 120mm/s being on the slow end. But I don't use it that often because I am also not a fan of bowden feed.. my problem, I know, and I really need to get over it. My workhorses are the SD4s. They get the job done, and done nicely, with little fuss or need of constant tweaking to get things going. They just work.

My concern with speed has part to do with having projects done before bed time, but also get each layer complete before it fully cools as that the next layer hold to it well which which with more complex models becomes an issue. If more nozzles working at the same time is needed so be it.

My concern with speed has part to do with having projects done before bed time, but also get each layer complete before it fully cools as that the next layer hold to it well which which with more complex models becomes an issue. If more nozzles working at the same time is needed so be it.

You may be confused on how 3d printers and 3d printing in general works. You want the previous layer to cool some other wise the layers will squish from the next layer being pushed against it more than they should. There is no issue with the layers bonding as long as your machine is calibrated. Further more there is no printer that prints using multiple heads on the same model. The heads would get in the way of each other. There are printers that have multiple extruders on the same head and will switch from one color or material with in the same print. There are also multi head machines that will print copies or different models under each head at the same time but they are kept within their own area on the build platform.

All the printers on the market now work as they should. Some do it better and some do it worse. You get what you pay for or the amount of work you put into it a bad machine to make it better.

My point is you are making a mountain out of a mole hill and all your concerns are really of no concern as they are not an issue in current technology or in updated machines that are done correctly.

As for finishing before you go to bed, that is going to be hard even on fast machines. If you are concerned about fire the best option is putting the machine in a flame proof area or cabinet where it will just burn it's self down. Honestly though you are more likely to get hit by lightning than have your printer cause a fire as long as all the wiring is the correct size and all the joints are secure.

I have been printing for many years 10+ with the machine in my bed room and I have often run prints that take 12 to 24 hours and slept with it in the same room and leave it going when I am at work. My machine is all metal so there is very little that will burn even if it does have a problem. Not enough of a flame will be generated to ignite anything around it. But as I said if you are really concerned with fire then put it in a place where fire will be no issue. My buddy has his sitting in his fire place that he never uses.

Speed is not the end all / be all of 3d printing. the faster you run, the more quality of print will suffer

I have to agree with this statement my mp mini is rated for 55mm /sec . the MP ultimate is rated for 150 mm/sec .

there are two reasons i can not get that speed .

if i really ran at top speed the printer would rely shake and i tend to do smal prints .

for example a 2018 Lamborghini Huracán has a top speed of 201 mph and a 0-60 time of 2.9 sec. this is great for the track or an open highway but try driving this car on city streets and turning every few blocks. and see how fast you can go. If you are lucky you might get to 50-60 mph before you have to hit the brakes to decelerate .

The point here is on small parts you can only go so far before the print head has to slow down then speed up then slow down.....

And folks please do not try this in your neighborhood . As most residential neighborhoods the speed limit is 25 mph

I am not suggesting anyone attempt to break the speed limit. This is a hypothetical illustration

So if you really plan on printing on the entire bed you may be able to get upt to max speed. but you also better prepare to let the printer run overnight.

Yes I did mean multiple extruders on the same print head. I definitely want a water soluble support material to avoid destroying the model while removing support so overhangs of all kinds are not an issue at all.

Yes I did mean multiple extruders on the same print head. I definitely want a water soluble support material to avoid destroying the model while removing support so overhangs of all kinds are not an issue at all.

Not really necessary if things are properly calibrated. None of my printers have more than one head, and I can print things, with supports, and not "destroy" them when removing supports.

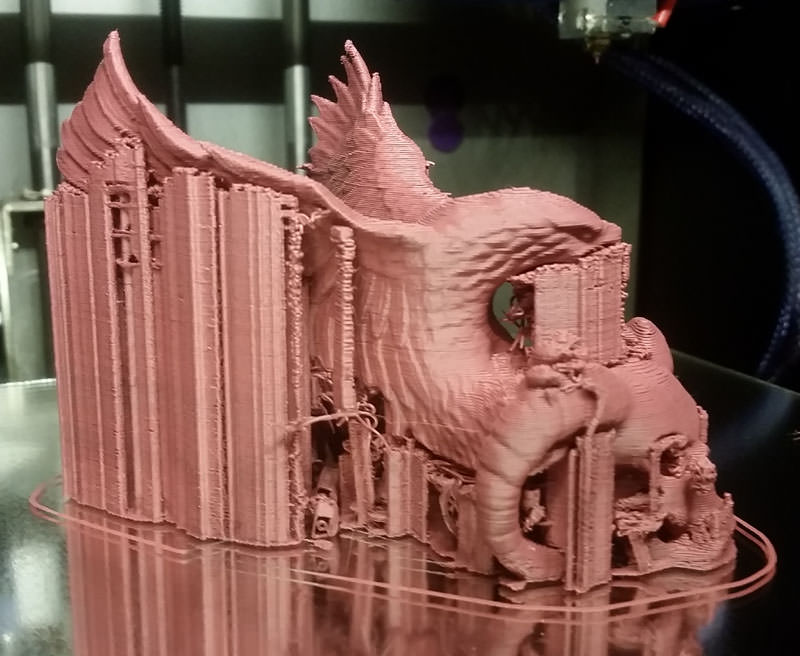

Case in point, this little item...

after removing supports...notice the quarter next to it for scale...

and this was done on my favorite SD4 with a new filament I had never used before - only thing other than this that I had printed with it were 2 very shallow 25x25mm calibration boxes to get it in the ball park.

you need to decide what material you want to use and what you want to print as each printer is made for a limited type material and out put. and like an old tech used to tell his customers "you can have cost, Quality, Speed but only pick any 2 but not all" features are dependent on things like this. maybe for your needs a different type 3D printer is needed like liquid resin or powder type which both can do great detail but not strong product for stress use more display models maybe working type for demonstration. stronger materials require lots higher price versions also each style has needed pre/post prep work and maybe lab room etc. people that offer all types of 3D printing services have many different printers to suit each need. there is no all in one or one size fits all. each material has its own hazards or limits cost being one also. so time & material jobs can very greatly depending on all the above. for e.g. a printer designed to produce a working 1911 45cal ACP hand gun can cost near a million dollars and to cover time & material etc plus small profit the hand gun must sell for like $5,000 when you can buy a hand full of Colt 45 auto 1911 handguns like 5 for same price and have them home from local gun shop b4 the 3D printed one is even 1% finished. so... this is why most 3D printer users make R&D models or scale model items like for model railroading etc.

What are the basic specs of all extruder 3D printers (Abs and pla) materials? Makerbot does produce higher detail than SD? What determines that? The Z axis thread height and nozzle diameter primarily?

there are two extruders that i would put on my printers the titan aero is combination of a titan extruder and a built in heat sink with heater block etc. The other is a bond tech. these are the standard on the new Prussia machines. and these can be combined with an E3d hot end or the new high end mosquito hot end. Irrc thes are also compatible with the micro Swiss.

As far as z axis control that is the lead screw. My Mono price ultimate maker has a 10-12 mm ball screw and iirc 12 mm guide rods. is has a specified min layer height of 0.02 mm.

Nozzles are switchable and range from .2 mm to .8 for the standard e3d system .

if you want a new solid printer take a look here.

http://www.soliforum.com/topic/17534/mo … -for-sale/

What are the basic specs of all extruder 3D printers (Abs and pla) materials? Makerbot does produce higher detail than SD? What determines that? The Z axis thread height and nozzle diameter primarily?

Layer height & nozzle diameter are the biggest factors. Proper calibration also plays an important factor.

No, Makerbot is not necessarily any better, or worse, than a Solidoodle, or any other FDM type 3d printer. Pretty much any 3d printer that is built solidly enough can produce quality prints with proper set up and calibration.

If you want super high resolution in small items, then you want to go with a resin type that can get down into the 0.025 micron range, rather than an FDM that does around 0.1 micron - 0.05 if you are really lucky and have it really dialed in well.

As an added note to the above images.. that item was printed at 0.2963mm layer height (SD equivalent of 0.3mm), with a 0.4 nozzle. Yes, I could have gone with a lower layer height for better results, but that would also have seriously increased the print time (which was near 6hrs as it was) All things considered, it did not turn out that badly.

Know of any machines with with internal ventilation? Like a separate container where the air gets blown into and a filter so you can print without much worry about breathing it in?

even the SD 2 had an optional enclosure like the one I own. and a couple later models also had 8x8 beds after SD4 which had a cutout in rear for exhaust fan to be added after market if wanted. also cooling fans for extruder tip to keep down shift/separation of layers could be added of later models or any as a DIY mod.

all these things & more have been addressed in many old posts on this group which can be searched for and read in topics/threads since group started years ago and mods posted can still be done with proper parts. most of us started with a basic printer like your SD2 and learned what we wanted to do and how/which 3D printer, Mods, Materials to use to get there. give it a try and allow yourself at least 1-2 years learning curve b4 over spending on something you may not require. about the only 3D printing FDM material you wont need enclosed or maybe vented is PLA, but it too has limits for some items which you need to research or try it to see. this industry is very much a "to each his own" kind of thing. remember all tech gets upgraded often so in a couple years what ever you buy after many hours use/abuse will need replaced too, and likely more affordable then.

What other variables are there besides layer height and nozzle diameter?

Heated print bed

Enclosure

Print space

Possible print speed?

Compatibility with print heads.

Multiple colors

Water soluble support materials in conjunction with ABS/PLA.

What else is there other than the overall quality of parts?

Also when talking about microns that is 1/1000mm? So the max. resolution of a FDM machine is 1/10,000 of a mm? Is this layer height or XY detail?

auto calibrate. the wiki you need is here http://www.soliwiki.com/

SoliForum - 3D Printing Community → Solidoodle Discussion → Confirm Solidoodle Model??

Powered by PunBB, supported by Informer Technologies, Inc.