Topic: Abandoned 3D trying to get working

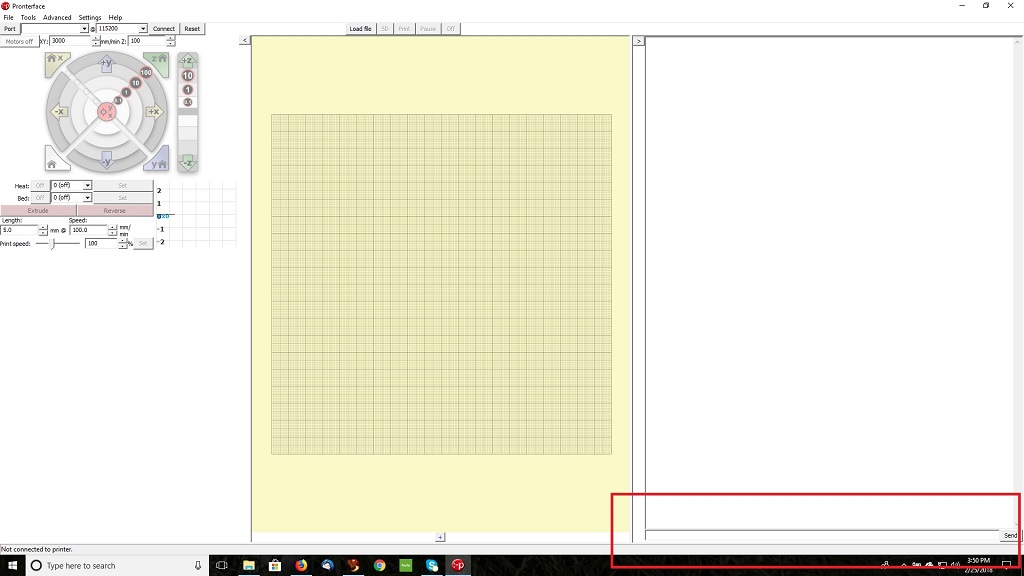

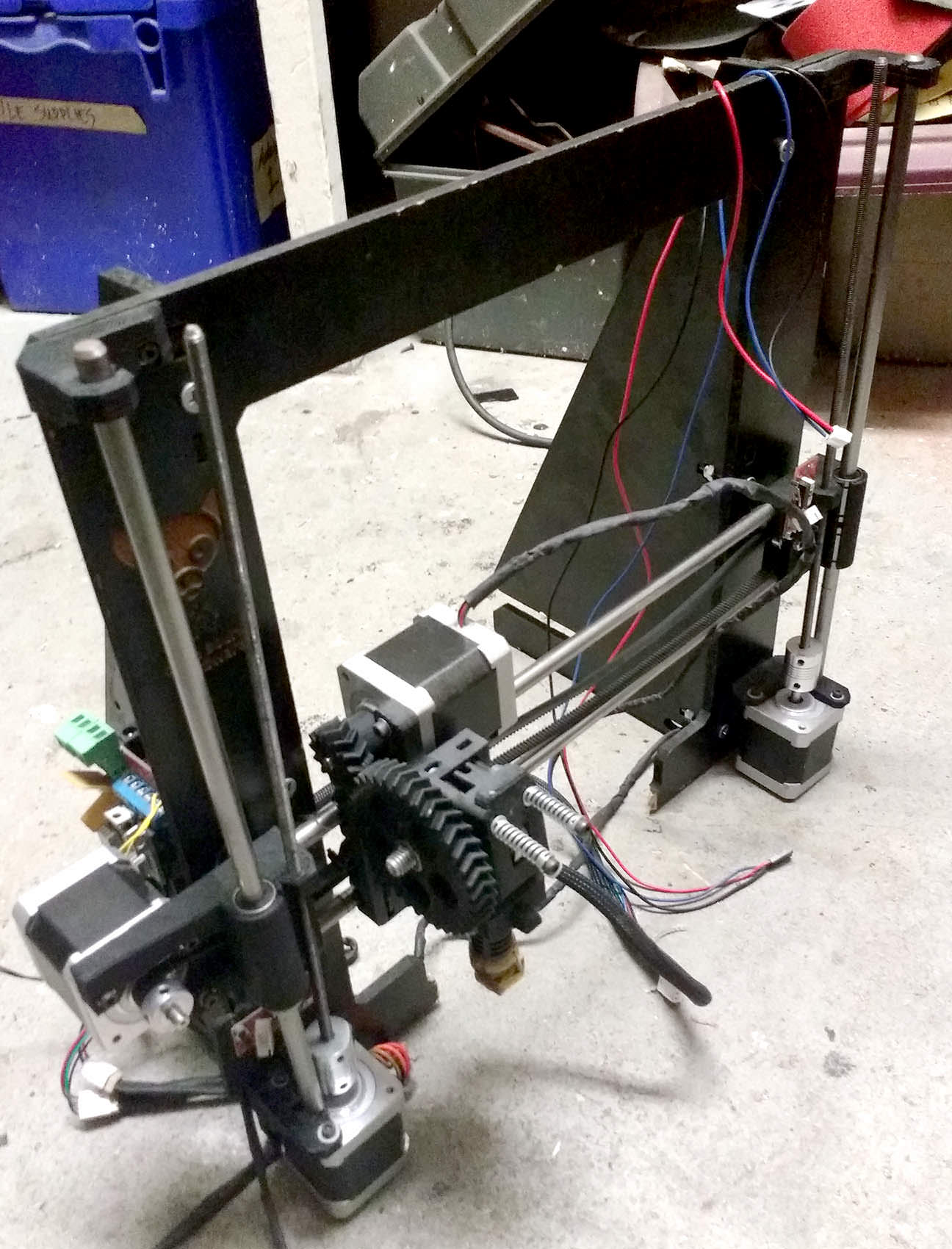

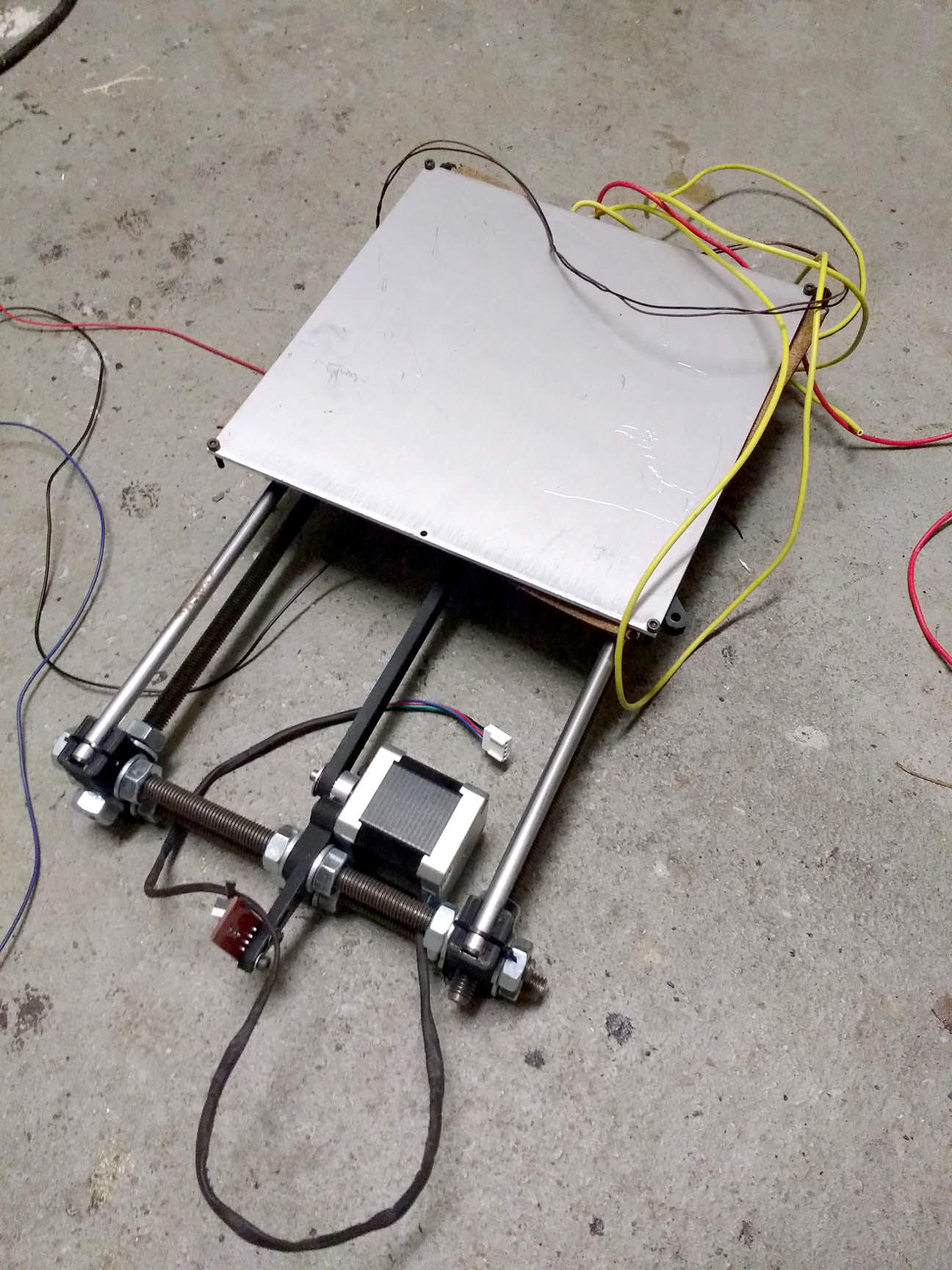

I picked up a Prusa i3 from the second hand shop. Seems like the guy who started building it gave up and or broke the frame before finishing it and gave up. That said i figured i'd try to get it to work. I fixed the frame and bought a bunch of parts and have it hooked to the computer.

I've been following miscellaneous guides on YouTube but feel I've reached a spot where I could use a little help. I came upon your forum when searching about the motors going in one direction. I have 3 mechanical end stops.

Oh I downloaded all the software so far from nwreprap and have used to talk to the printer and arduino.

Using Pronterface the motors will move in one direction which happens to be the opposite direction of the endstops. In my search a site asked. "If you issue an M119 command" Where how do you do this? Note I do not have an LED on this printer. I should add that when I plug in the 3D there is no auto home going on. The X, Y, Z positions stay there until I use Pronterface. Manually pushing the endstop does nothing (besides the red LED light coming on).

If anyone can give me a few things to try or look at I would appreciate the insight.