Topic: SD3 Y axis under printing?

Hi,

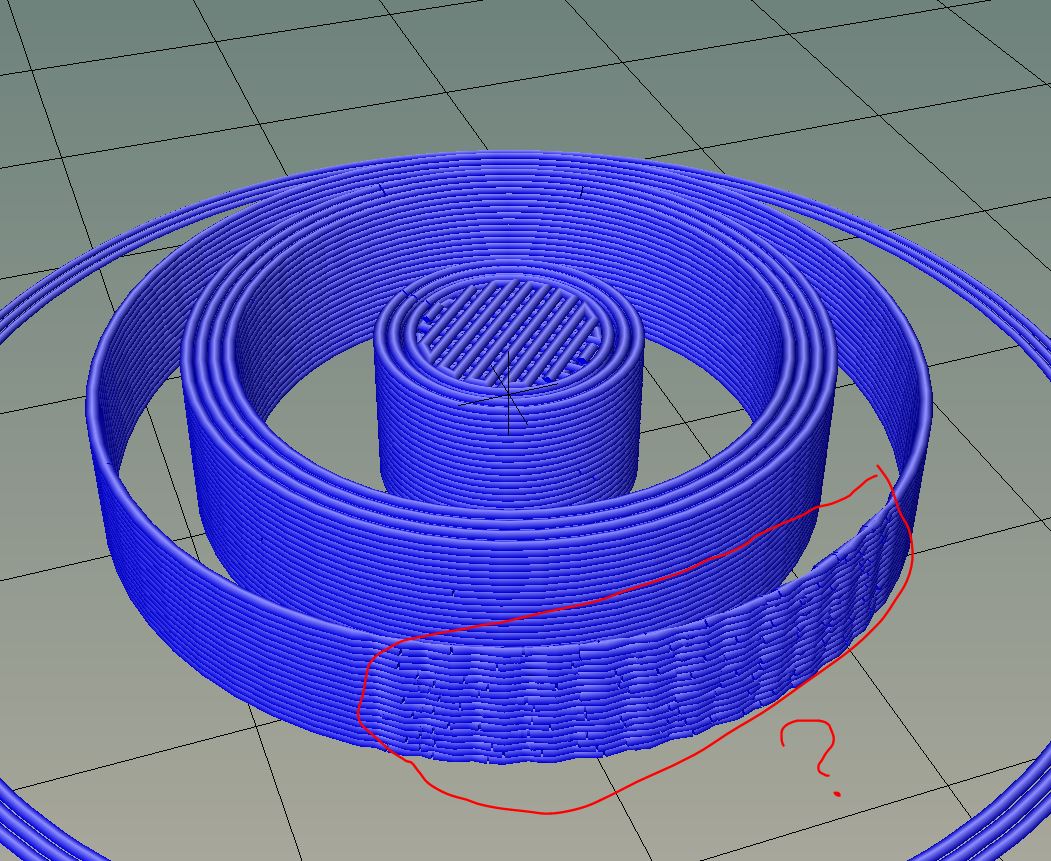

There's a problem with the Y axis. I printed a part with perpendicular slots (slots that run along the X axis and slots that run along the Y axis), and realized there's a gap between the infill and the parameter along the slot edges that are parallel to the X axis which means the Y axis did not travel enough to fill the infill all the way to the parameter.

I measure the overall size of the part and sure enough:

X dimension = 70.05mm (nominal = 70mm)

Y dimension = 69.50mm (nominal = 70mm)

This means the X travel is pretty spot on. But the Y axis travel is 0.5mm short over a 70mm travel distance.

How can I fix the Y axis travel distance? How can I compensate for the short travel distance of the Y axis?

Any tips are much needed and appreciated! ![]()

PS: Sorry for the many posts by me in the last couple of days...this is one of the last things I have to do to get my printer up and running decently!