Topic: Glass Bed

Something I would like to try sometime-

People have been looking for an alternative to Kapton, so I was thinking of trying out glass and glue similar to the Cube.

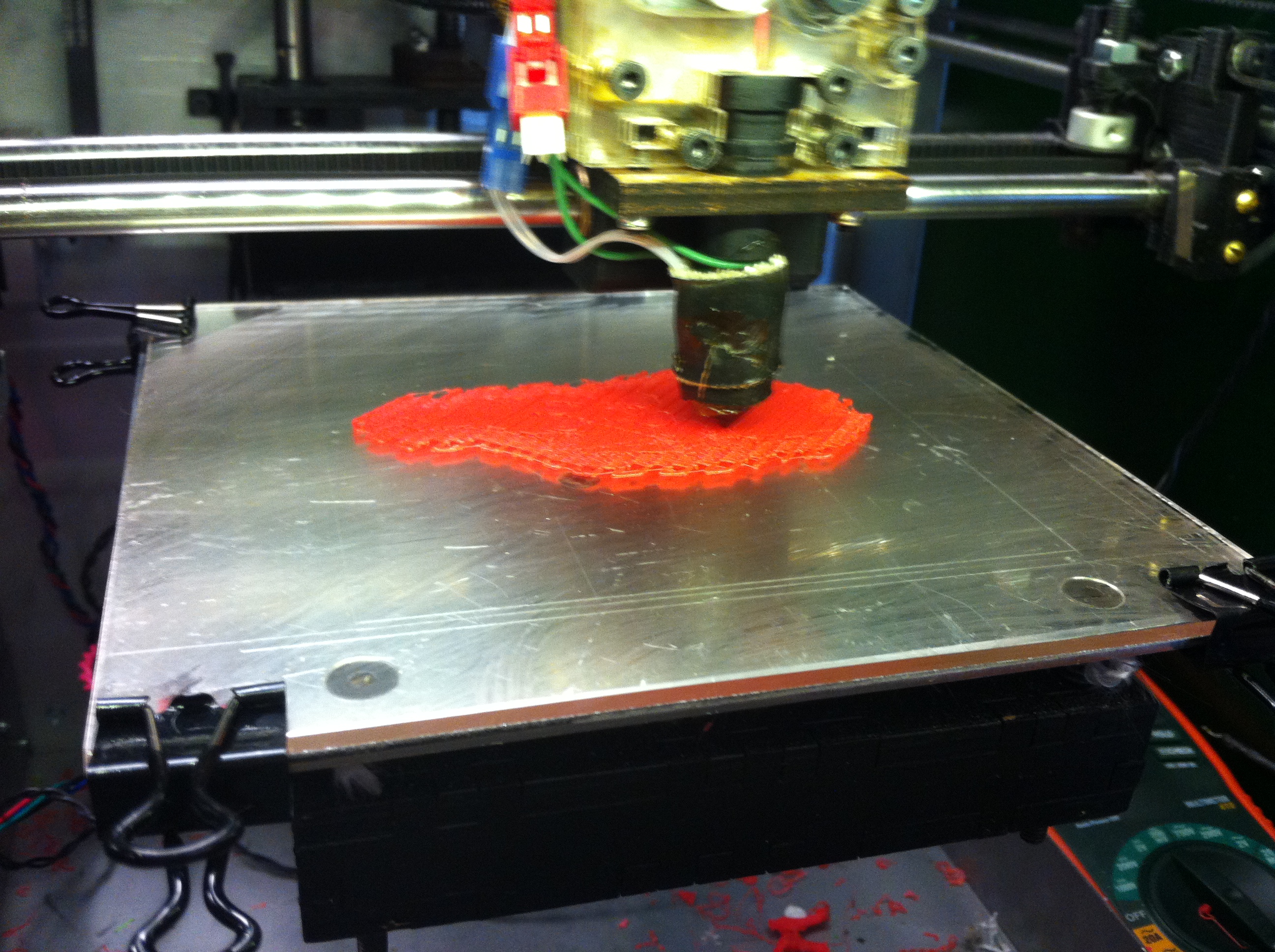

Get a few pieces of glass cut to 150x150. Make sure the bed is level (because you will cover the screws) and then clip the glass onto the aluminum with some binder clips. Spread a mixture of PVA glue, diluted 5:1 with water, over the glass and print.

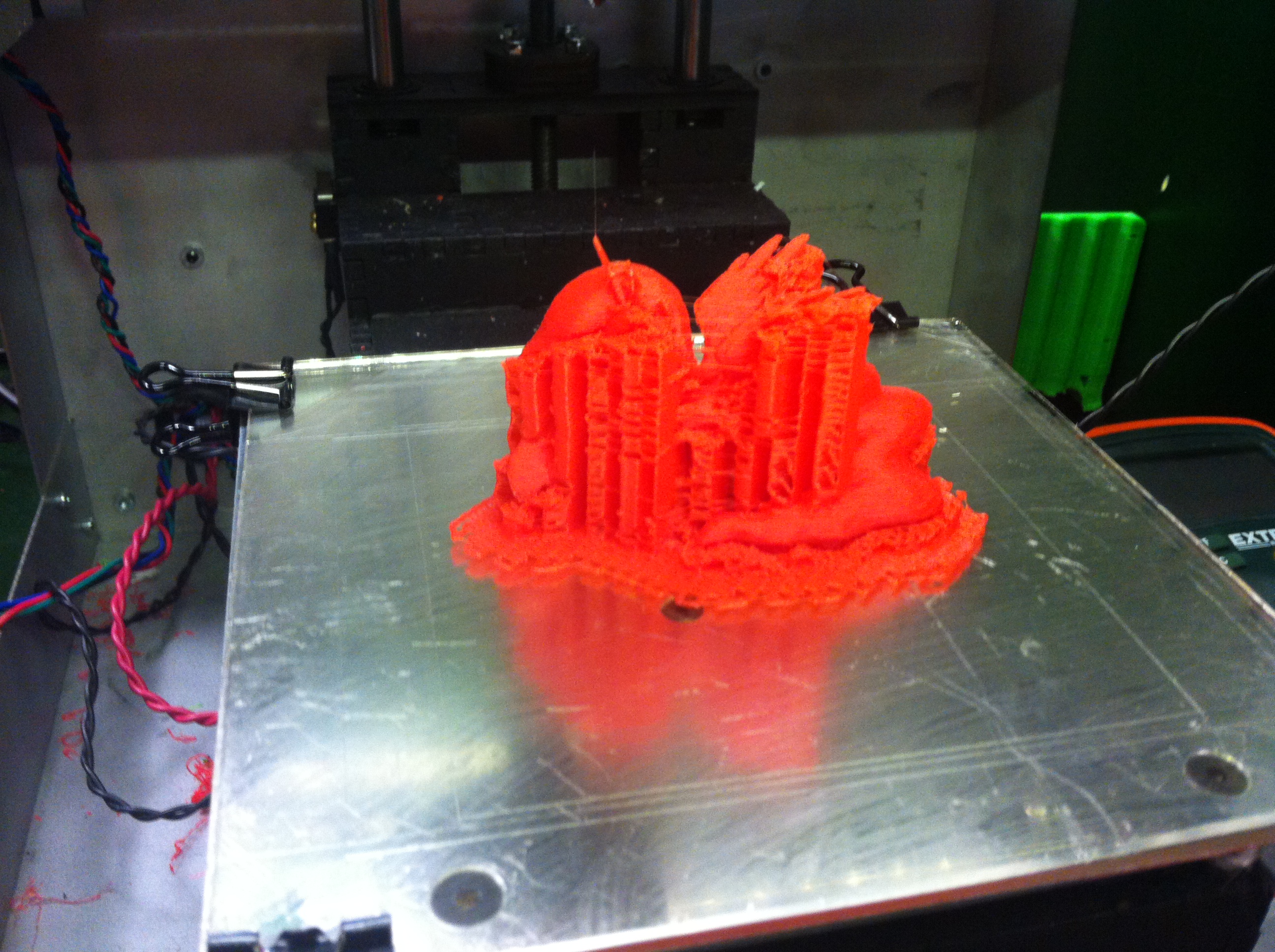

When the print is done, unclip the glass and set it aside, clip another sheet that you have already glued to the bed and start your next print while the first one cools.

Take your first print to the sink to remove the part and rinse it off.

Bare glass is generally better for PLA, but it could work for ABS with the glue. I don't know how much loss of heat there would be from the aluminum to glass, if any. It might be hard to get a good reading with an IR thermometer since the glass is clear and the aluminum is reflective. Using the backside of a mirror might help there, though I don't know if the coating would be prone to peeling with the removal of prints.

Another addition that would go well with this would be some method of attaching thumbwheels to the bottom of the leveling screws. Maybe if the screws were longer, there might be some way of jamming a thumbwheel between a couple of nuts, and using that to adjust the level.