Re: Sintron Delta Build - Buyer Beware!

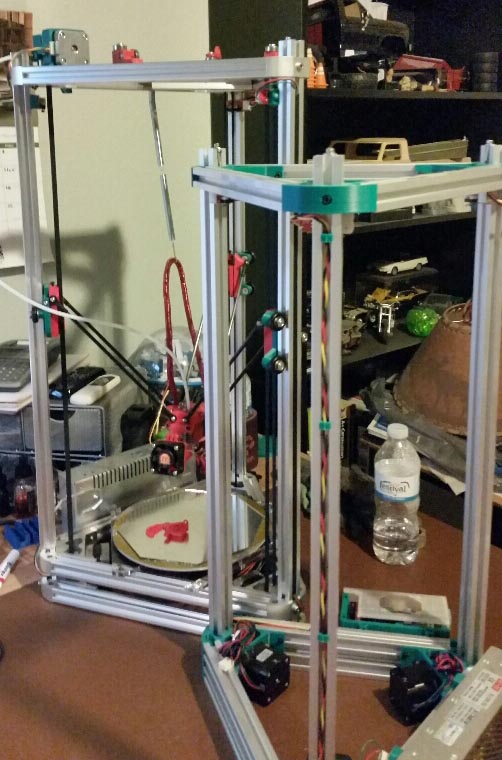

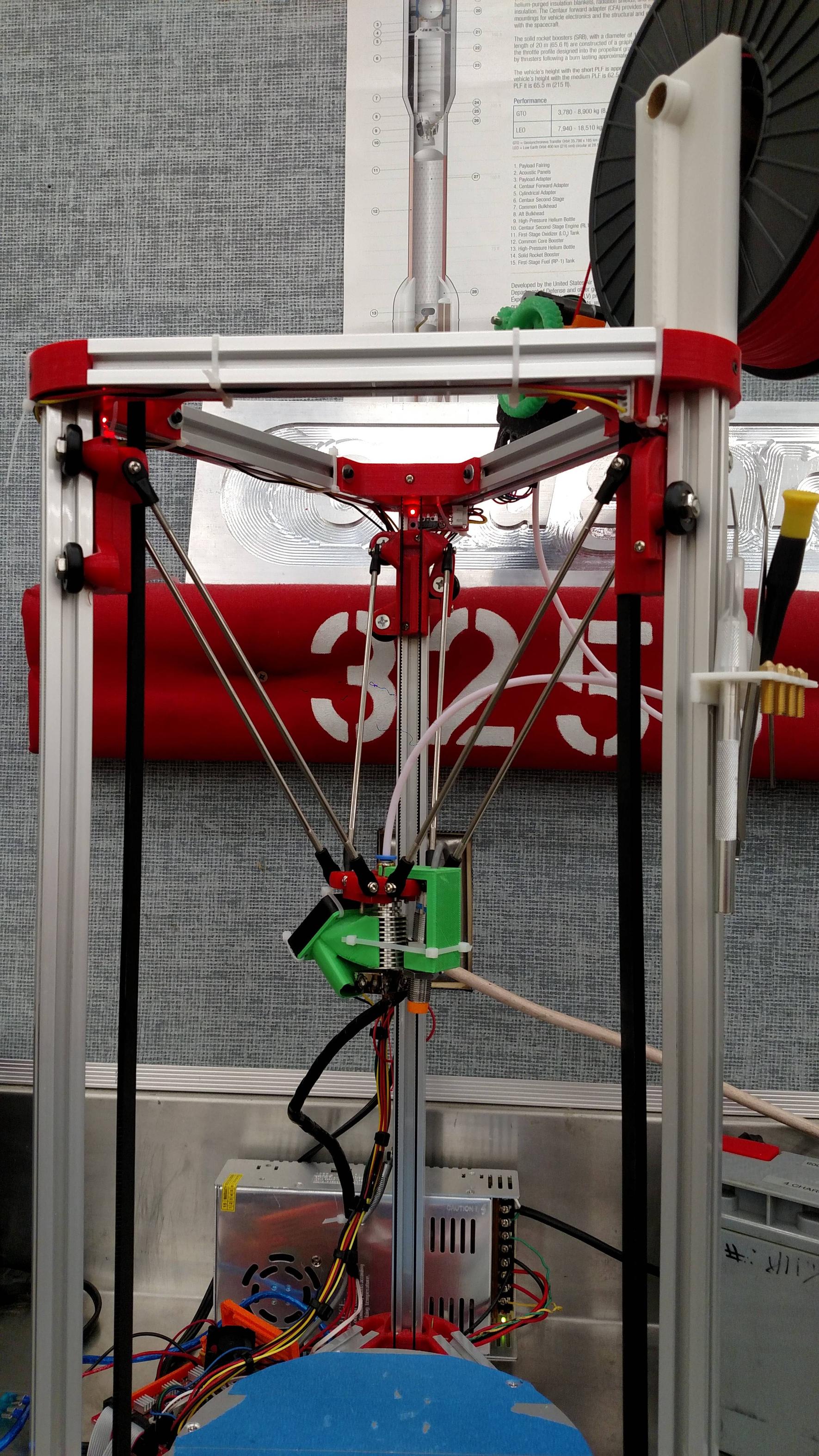

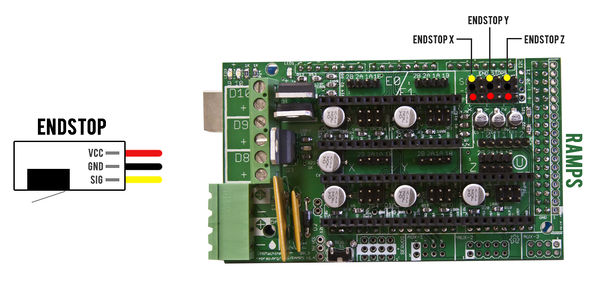

I bought this kit in November last year and still trying to get it to work. Had dodgy RAMPS board and defective thermistor on extruder. Managed to break one of the main printed junctions at the bottom while putting the frame together that's when I discovered all parts are made from PLA (what would it have cost them to make it in ABS, a few cents more?) was able to glue it back together with epoxy but one day might reprint the whole thing myself in ABS. Fan housing was missing from the kit. Could not find website that showed assembly instructions, mostly I just used pictures from their ebay shop. Asked Sintron about instructions for the fitting of the Z probe (so what do you do with 2 safety pins?) and they replied that the instructions were on page 72. Page 72 of what? They could not tell me and used the old "me no speak English" trick. For wiring the RAMPS they referred me to a website with diagram that was for totally different board. I downloaded the firmware and installed after many difficulties, one being that it instructs the user to replace the config.h file and config.adv with another version from a directory that downloads with it. NO! Sintron says not to do this, so why could they not just delete this information and save days of wasted time while following erroneous information?

So now I have semi functional printer, extruder and hot bed work, motors work, end stops have power but no functionality. Dived into the firmware again and on close inspection found command lines incomplete regarding max end stop inverting. So now end stops will stop motors but!!!!

I have a notion that all axis should rise, hit end stops to set the height above the bed, maybe wrong about this, as there are no instructions for the setup its hard to tell. Anyway only the Z axis works on the end stop and shut off other axis so I can't home the printer; anyone out there knows where I can find information on the homing and calibration of this printer?

Think I just answered my own question, check out the following website.

http://www.think3dprint3d.com/3D-Printer-Kits/ go to Kossel Mini and then Documentation tab. Very detailed description of Z probe setup and calibration of Delta printer, not specifically for the Sintron but close enough. Also used this site to put the thing together plenty of good images and useful information.