Topic: Extruder gouging solidoodle filament

I've read through some other threads and if I've overlooked a fix for this, please just send me there and delete this thread. I've thoroughly cleaned the gear out and made sure that the end is not clogged (can pan filament through) but when I load up the filament I get about 50mm worth or printing and the flow stops. The gear continues to move smoothly and the end is still hot. When I stop it and take the filament out, there is a gouge which makes me believe that the gouge won't allow the filament to continue down into the hot end stopping the flow of filament and pressure. The gear will also be filthy with filament dust again.

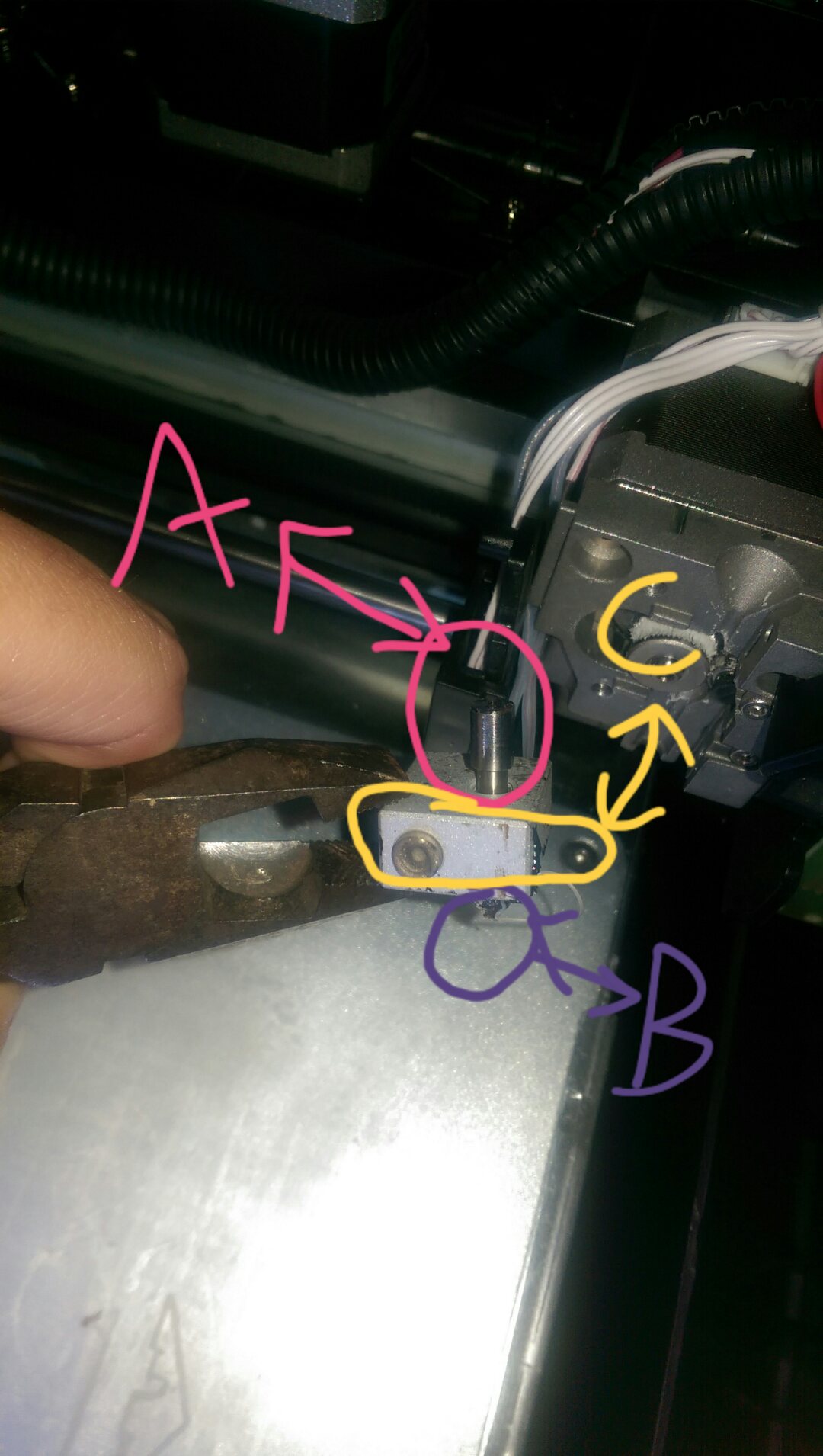

Here is a pic of slightly gouged filament though I've had much worse.