In theory it should help, but it didn't make much difference in practice to me if everything else was calibrated already.

Just wiggle the frame the Y motor is on and the frames the brackets are on while it prints circles or similar and you'll see you can't spot any difference.

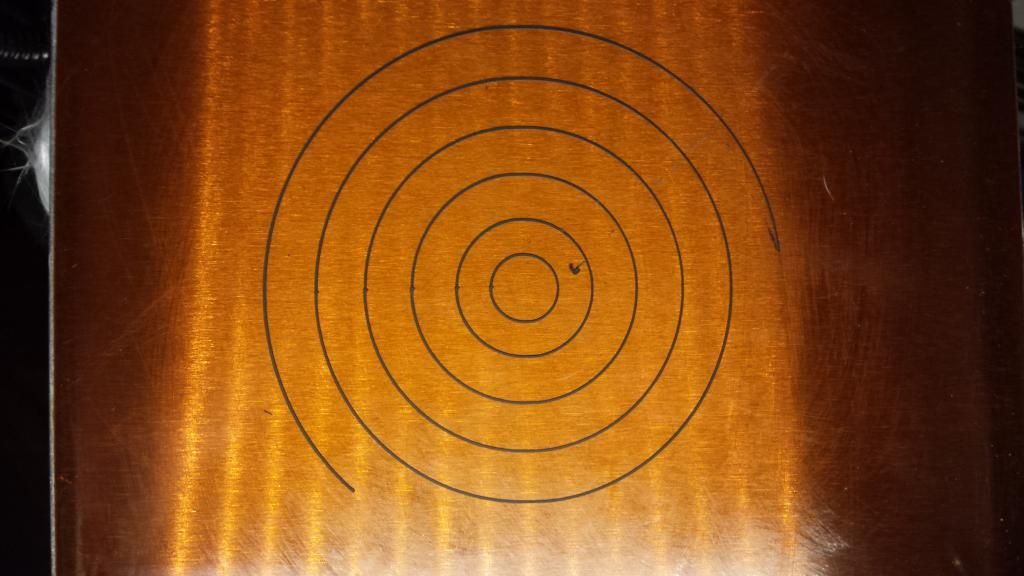

There's a backlash in the after photo. It's not much, maybe less for the OP than before, but its there.

What is it then? I don't know man, I'm fed up with this. I'll try out the direct drive mod when my couplers and heatbed arrive as I can't print anything at all at this point, maybe my heater is damaged or something.

If there's no backlash with direct drive, then side belts/pulleys and front brackets just can't be the issue and the only possibilities will remain the short motor belt, drive rod bending or back frame bending as possible issues. There's nothing left then.

Solidoodle 4