well... that was interesting.. had a reply all typed up, hit the submit button, and poof! it was gone..

Lets try this again....

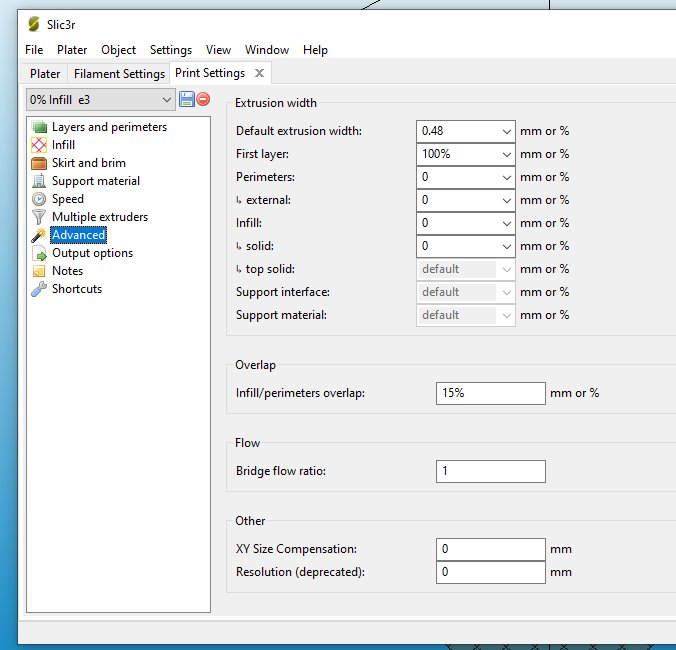

Ya'all seem to forget, I have used only RH for ~7 years. I am somewhat familiar with it. The SD settings I refer to are mostly the filament diameter/multiplier/0.4 nozzle. An ideal 1.75/1.0/0.4 nozzle @200C should produce 0.48 on any printer. I have 18 rolls of filament in 2 air tight containers with desiccant packages in with the filament. All were measured and calibrated to produce viable prints. I should be able to give you a roll of my filament along with the calibration numbers and you should be able to use it by just inputting my numbers.

and this is why I am so confused on why you are having so many problems.. yo do have some experience

As far as the filament settings go, yes, you 'should' be able to reuse them... but not temps - temp will vary depending on the hotend - you should know this as well.. think about the difference in temps between the stock SD hotend and the E3D.. for me at least, that difference was HUGE.

(just as an aside - have over 45 spools, in 4 containers, and 5 printers.. three SD4s, an FT-5 and the Horizon beta tester - All require different print settings.. layer height is just that, the desired layer height.. everything else is different - even among the three SD4s)

I overdid the 100mm calibration. I nicked the filament with a razor blade at 100mm, rubbed a marker over the nick, then wiped it off, leaving me with a black line at 100mm. I could just see it at the end.

Excellent! Now try the test that wardjr suggested and add some resistance to the mix...

I have 2 new 0.4 nozzles. 1 from the new printer and 1 from the E3D. I'm gonna use the E3D (I trust more) which will require a major z height adjustment and re-leveling as E3D's is noticeably shorter. Not something I look forward to on this machine. I'll change nozzle and start at the beginning of the cali doc and have at it again!

When you change that nozzle, take the time to make sure the path thru the hotend is clear and unobstructed before putting the new nozzle on.

SD4 #1 & #2 - Lawsy carriages, E3D v6, Rumba controller board, mirror bed plate, X motor fan, upgraded PSU & Mica bed heater

SD4 #3 - in the works ~ Folgertech FT-5, rev 1

Printit Industries Beta Tester - Horizon H1