Topic: New printer - need help...

Some of you have watched my fiasco with a 7 y.o. SD2 and a new 32bit board - more on that later. I went ahead and bought a Creatily Ender 3D pro. Contrary to most beliefs, it's a well constructed machine, at least in comparison with the SD. All metal construction, no plastic, all 13 drive wheels are rubber riding on sealed roller bearings, etc. Comes with all the tools needed for construction, although they are a little archaic - 5 Allen wrenches, wrench, screwdriver, small wire cutter, etc.. All small parts were bagged with an extra screw of each type enclosed. Shipping said 10 - 14 days, I got it in 6. Very well packaged too. Assembly instructions are typical and could be expanded on.

My problems are with calibration. I used to set the SD nozzle height with a specific calling card - about 0.011" thick. Ender specifies a sheet of paper. They also use a soft magnetic piece of something that covers the build surface. I will replace mine tomorrow with some 230mm sq glass. Set at paper thickness, I managed to heat score a trail of everywhere the extruder went. The factory preset temps - 200C ext and 60C bed heat up in 3 min or less. Got the height set using the calling card as a start.

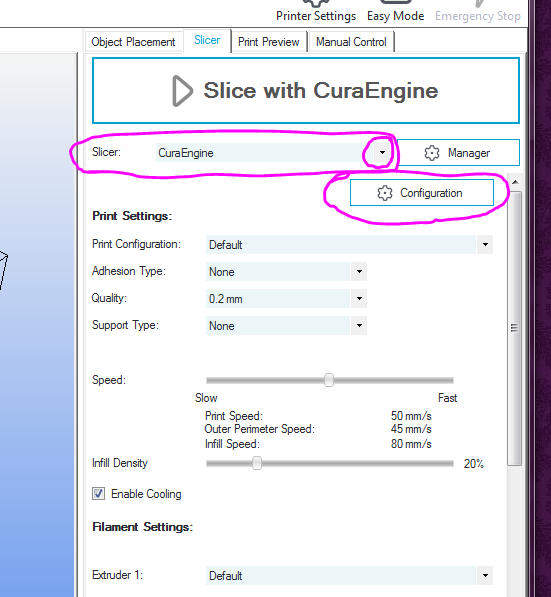

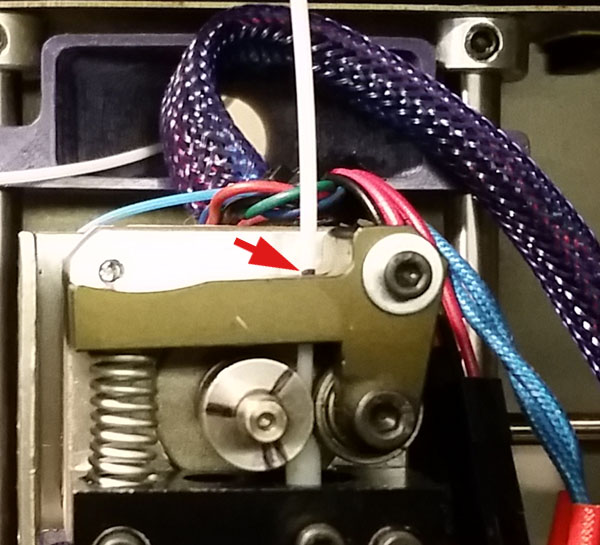

I left all the SD settings in RH untouched. Note the pic below...

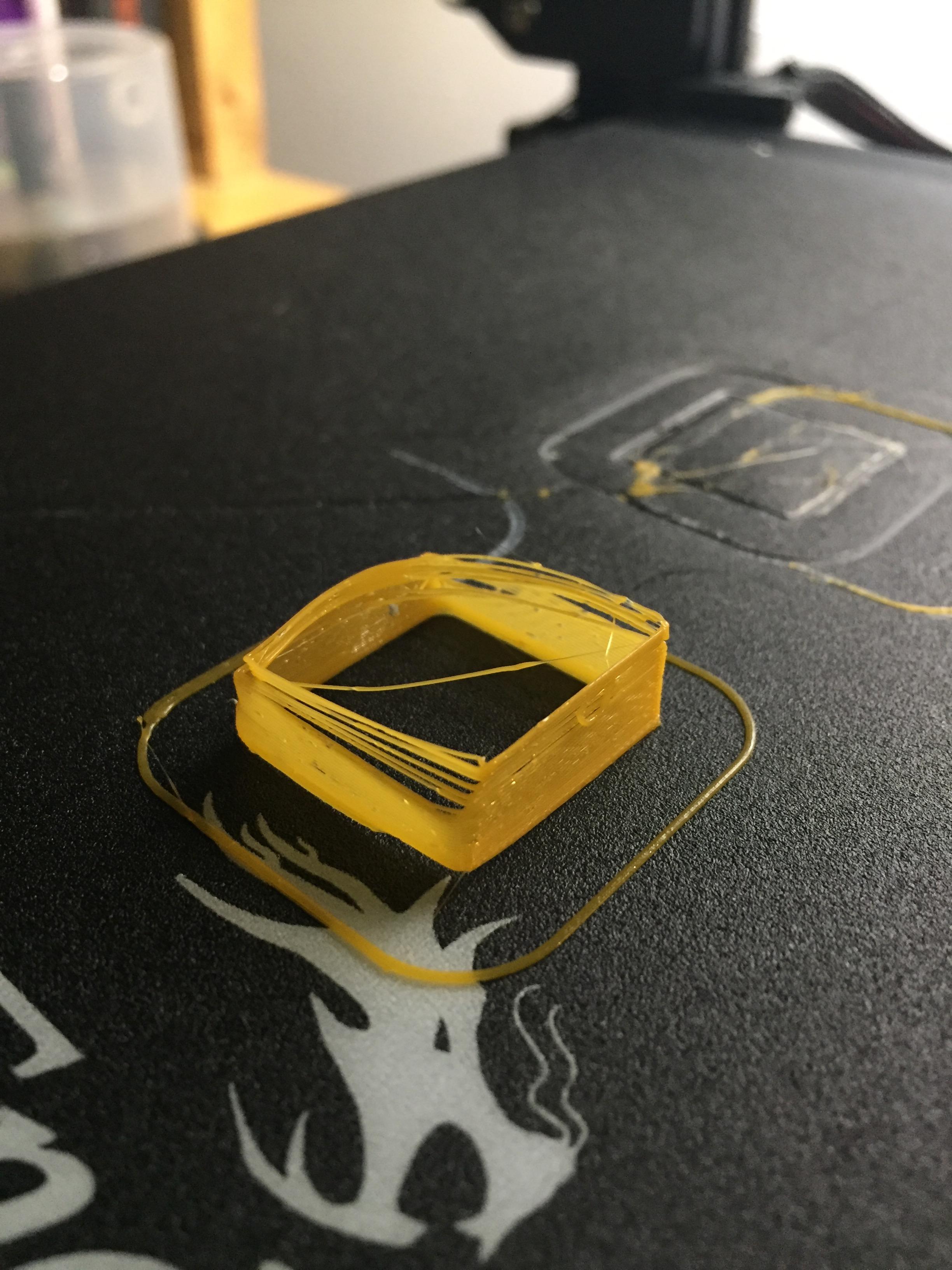

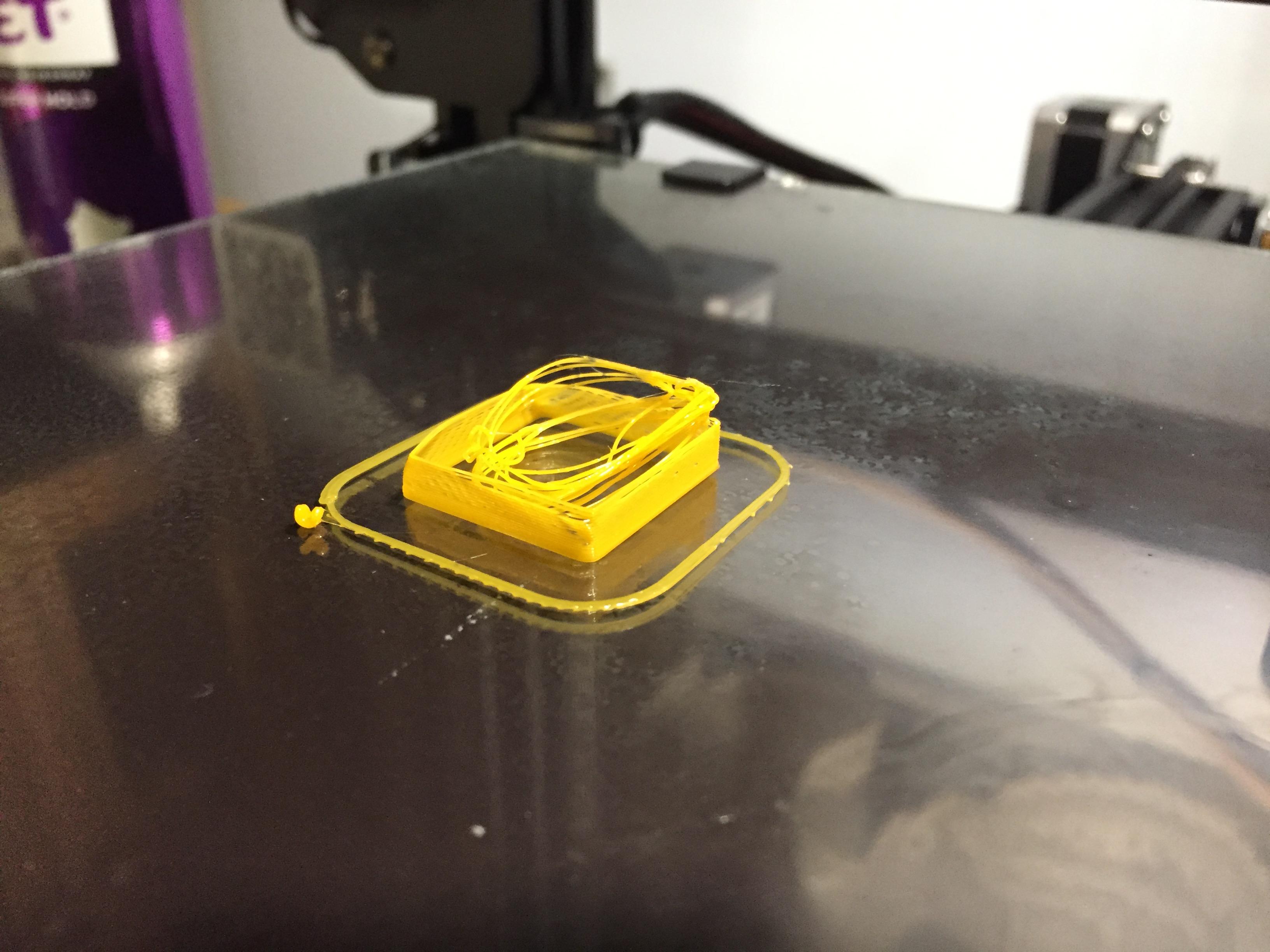

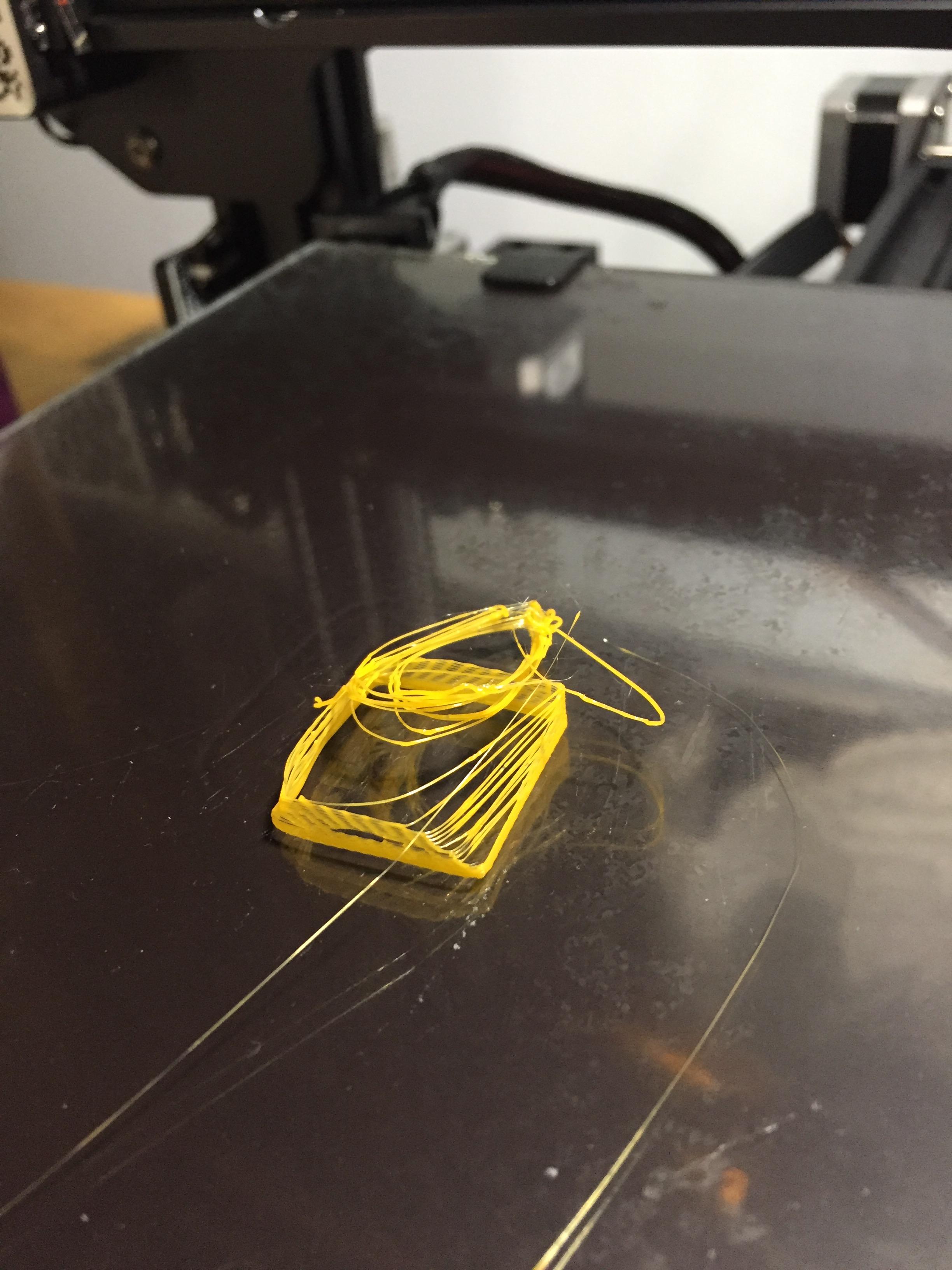

Got the adhesion going, at least til tomorrow when I change the print surface, But what is wrong with the filament feed? The 4 were printed on the Win box with RH (latest ver) and the single was printed on the Mac with RH again. I used all the original SD filament settings at first - ex: dia 1.72, multi .93, etc. each being different for each color, and each worked very well on the SD, then after fail went to default dia 1.75 - multi 1.0. Cannot figure out how to increase the wall thickness on RH, 2 versions of Cura and an old version of Simplify. No matter where I set the filament settings in all 3 of the slicers, it comes out ~0.38, 0.39 wall thickness. The black print I managed to get a little thicker by upping the flow rate to 115% in RH "Manual Control".

P.S. if Cura 4.7 is the best they got... stick with RH!

Help greatly appreciated - sorry for being so long...

About the SD and the BigTree-Tech SKR V1.3. I will gladly pay someone for a viable working copy of Marlin 2.0 that will make the SD work as it should.... Shoot, it's only 7 years old - just getting broke in rite... Contact me by email.