Re: SD3 w/ new e3d upgrade, issues with prints collapsing in

delorean175 wrote:So I really tried my absolute best so square up everything in terms of the rods. I measured, I used a right angle, it looks perfectly square. It made the circles worse. Something isn't right at all. Is it possible to calibrate the steps needed for the X and Y axis? It should be sorta like calibrating the extruder feed rate right? could you post your EEPROM settings?

No, I will not post EEPROM settings, because you should never use settings from someone else's printer. Each printer is unique in what it needs.

carriages need to be squared up and in a neutral position on the Y rods (no binding)

belts need to be tight and running true - there should be no deviation in the path

Don't forget to adjust the X belt as well - it should be running level and tight.there should not be "slop" anywhere

now, all of that aside.. how much wiggle does the front of your bed have?? if you put your finger on the center front, and wiggle side to side.. how much does it move? That can also be a source of out of round circles and other anomalies

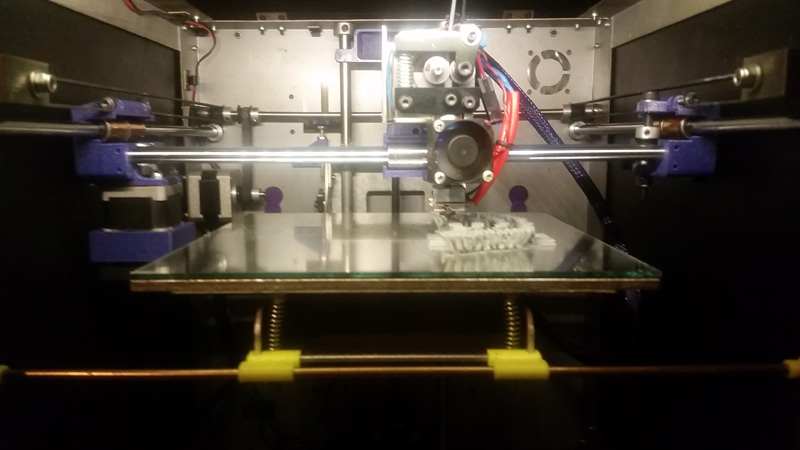

The belts seam to be tight and even. I get a low tone when I pluck them. Both make the same note. Same for the X belt. I'm really starting to look at the carriages them selves. The bearings sit loosely in them. I rolled the tape around them to help tighten it up but they still have a little wiggle. When the belts are tight and everything is tightened down they don't have any slop in them. I'll try to run through everything again.

I didn't finish going through all of your spool calibration write up last night. But I did the 7 measurements part, averaged that up and inputted the number into slic3r, re-calibrated the feed rate. I had just enough time to print off one calibration box. The extrusion was way better. The edges of the box sit flat now. The walls measured out to .35mm thick. So I'm going in the right direction. The box its self measured 10mm wide 8.3mm deep. So its still not perfectly square but the extrusion looks really nice. :-)

I drew up a 100mm by 100mm box with a single wall thickness. Front to back is measures 99mm and side to side it measures 100mm. The walls look 90 degrees. I'll check that to be sure in a little bit here. The box is short 1mm on the Y axis. Could belt length effect this? Like stretched out belts? My belts are 5 years old. They are tight though.

The front of my print bed has a stabilizer bar on it. So it doesn't move a whole lot. It has a tiny bit of wiggle though. But it looks like its wiggling at the bed leveling screws not the aluminum platform thing. I don't see any flexing at the rivets.