Topic: SD3 w/ new e3d upgrade, issues with prints collapsing in

Hello all,

I have an DS3 with a new E3d V6 and a new print bed. I used a MOSFET setup for my Bed and Extruder instead of a solid state relay. I have good adhesion and I think the bed temp is good (90C) I ran the factory extruder for many years and I got it pretty dialed in. I actually made some really decent prints. It finally died on me. I tried a knock off E3D made by GulfCoast Robotics, it was terrible. I had nothing but jamming and skipping issues at all temps. I messed with it for a while and gave up. I never managed to get one whole print from it. So I bought the real E3D.

After issues with versions of Marlin and teensyduino I managed to get a .hex file from Knowback who is running the same extruder. I believe the temps readings are correct now.

I'm having issues with my prints, I believe I have a few issues actually. I've been tweaking settings off and on for days and can't manage to get a print to go over 10 layers without (what looks like) over extruding or something. A .3mm wall box will collapse in like a pyramid. A cylinder will look like a cooling tower at a nuclear power plant. lol After playing with the extrusion width settings I managed to get nothing coming out of the nozzle after about 5 layers, it wasn't skipping either. The stepper motor wasn't turning at all. I since went back to basic width settings and that stopped.

I'm a bit stumped. I feel like the temps are way too hot because of the melting. My temp readings are 225. At 190 I get the same problem only not as messy. When the temps are set below 187C the extruder skips. Also when I set the extrusion multiplier to .9 or higher it skips, I currently have it at .65 and it doesn't skip.

Things I've done so far:

Set VREF (I believe correctly) for the Z. I set the others and they run way smoother now, but not contributing to my current issue.

Set PID values

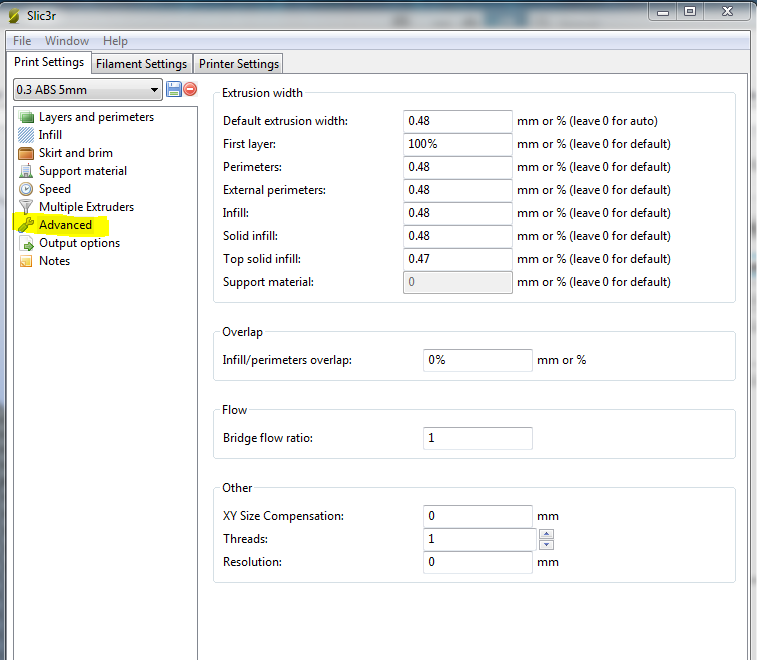

extrusion width set to .48 for .1mm layer height (was.42) I set the other values to 0 today.

played with extrusion multiplier

played with extrusion widths

played with temperatures or the bed and the extruder. Currently trying Extruder 225C Bed 90C

tried 225C for first layer 220, 115, 110 for other layers

Played with speed settings

rechecked filament diameter (1.74)

calibrated extruder filament going into the extruder.

I've always had issues with my inner layers, the width of the extrusion was always a little narrow. I adjusted that today and still have the same issue, as noted in the last pic. But it always made good looking prints and never did this, so I believe this issue could be separate.

Let me know what you guys think. I feel like I missed something somewhere.