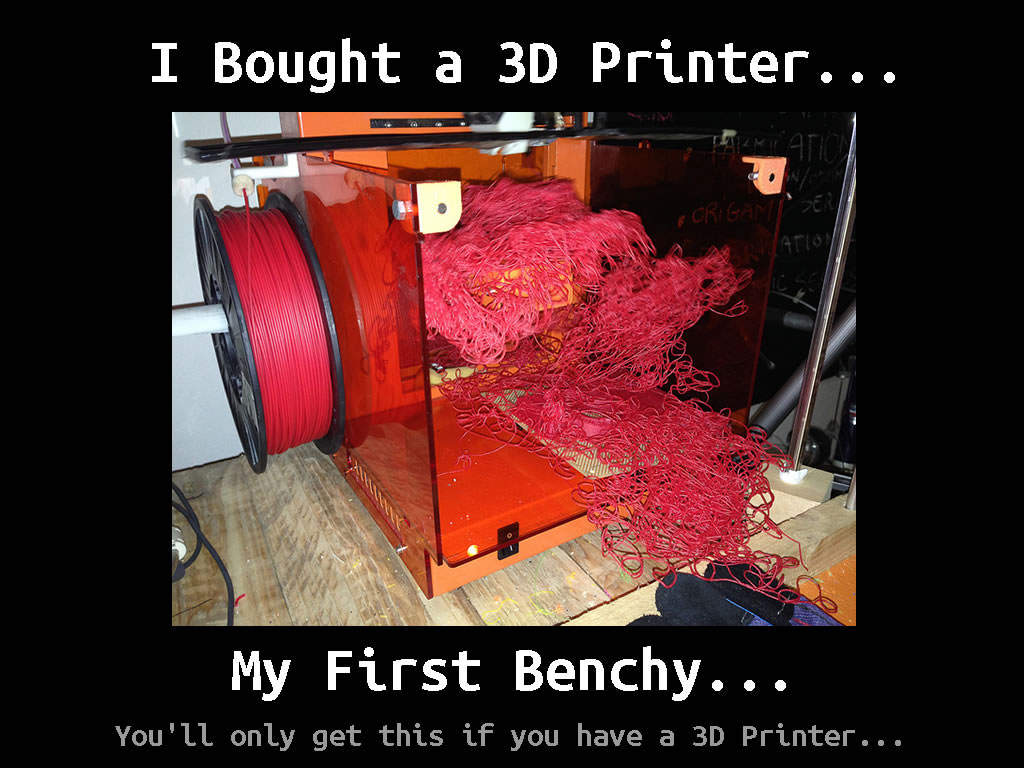

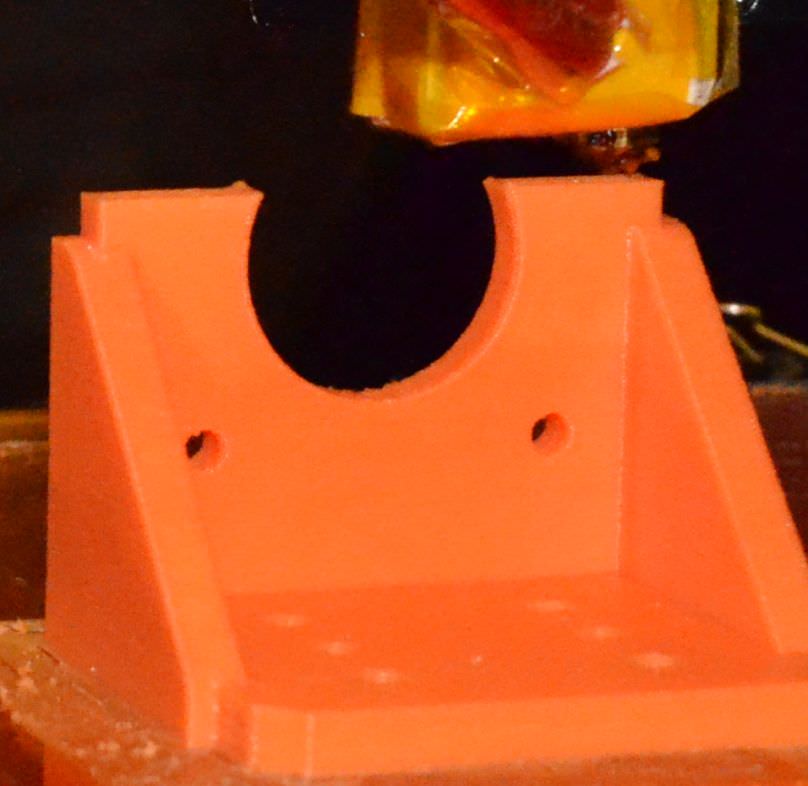

mark.giblin wrote:The results of my very first print, no fiddling before hand, I wanted to get an idea of just how good my building is because you may agree, build has something to do with the amount of fine tuning that you need to do.

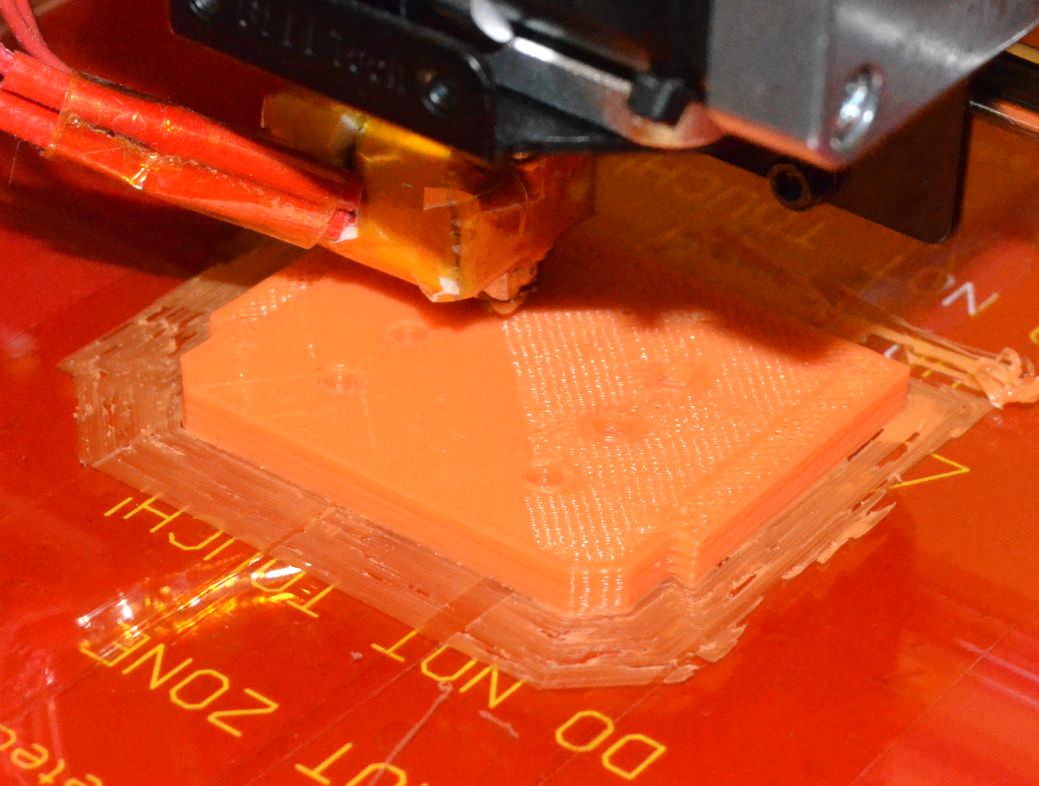

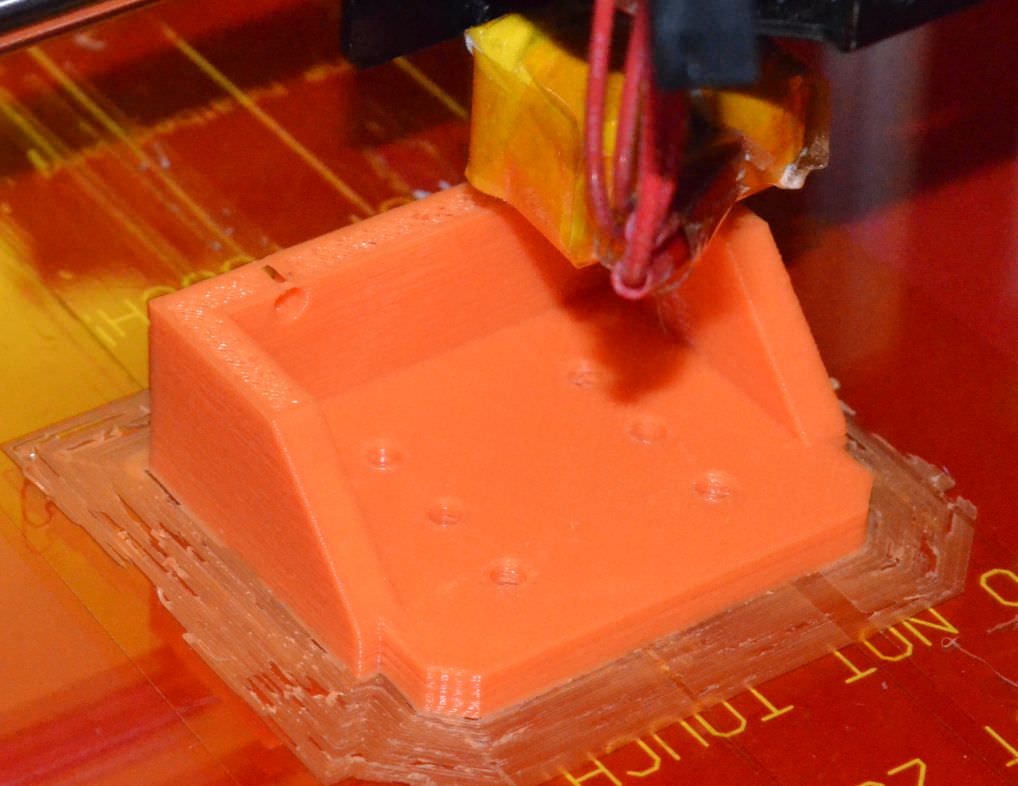

These were done with a 0.2mm layer height

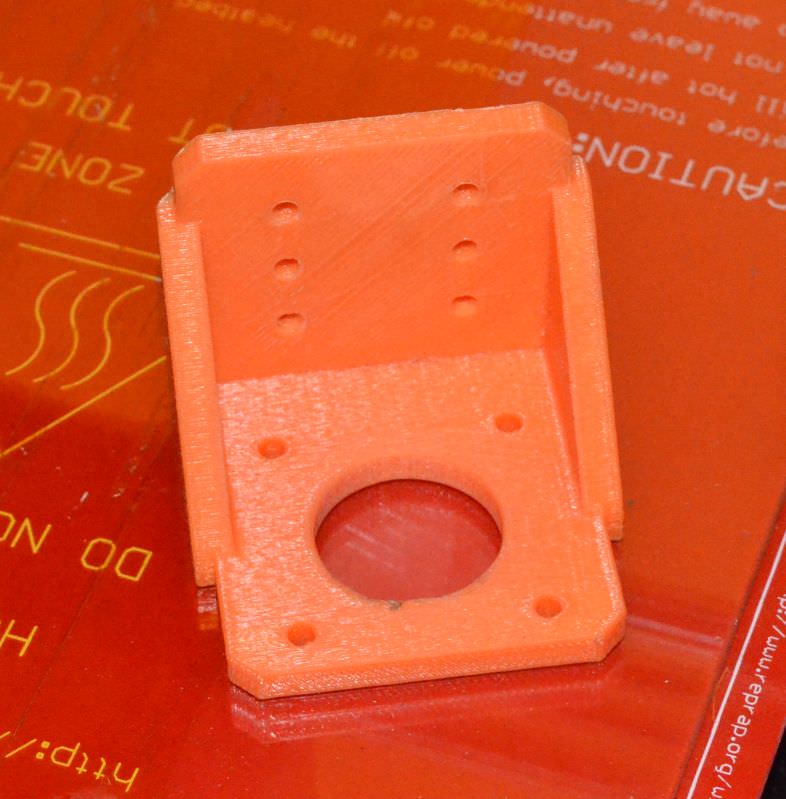

Only one minor defect but that is not going to take away from the rigidity or strength as I chose to go for a 40% infill with 1.2mm walls seeing as this is going to be a structural part... I wasn't going to wait 12 hours for a completely solid print.

Really appreciated all the input, very helpful and hope that this thread is helpful to others who are unfortunate enough to have bought one of these printers.

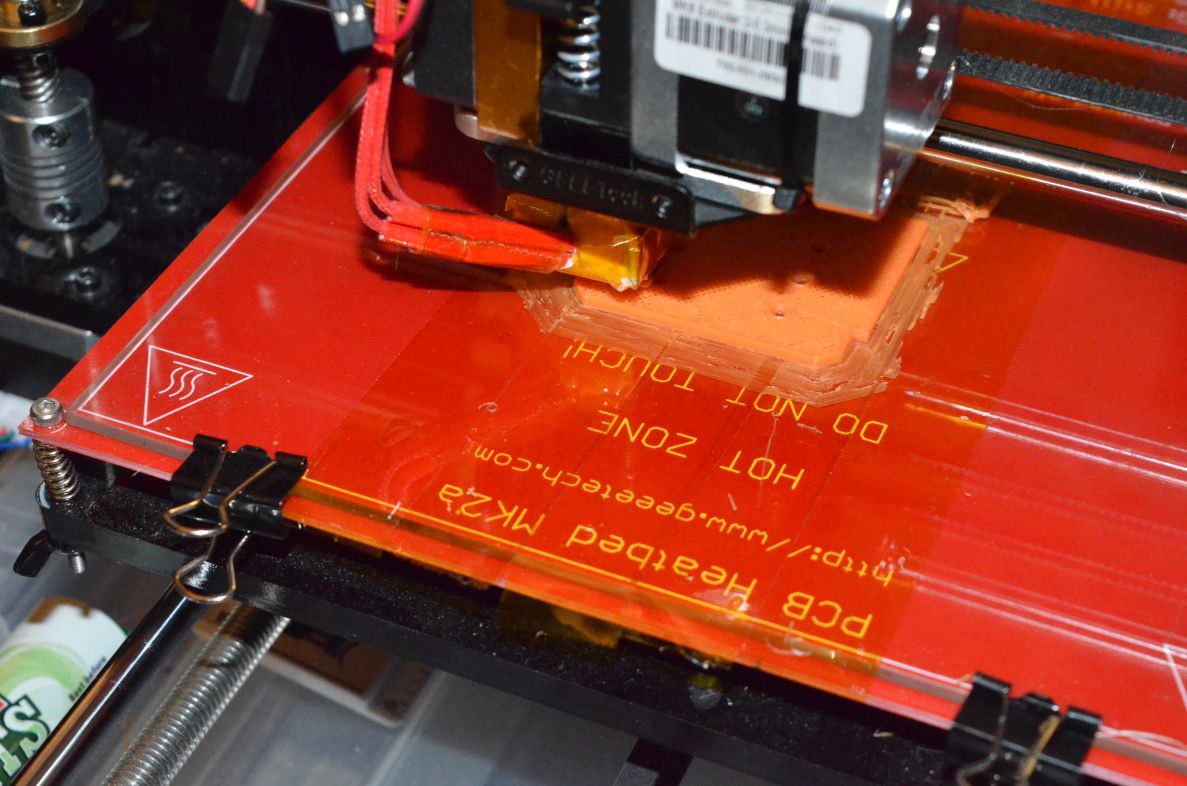

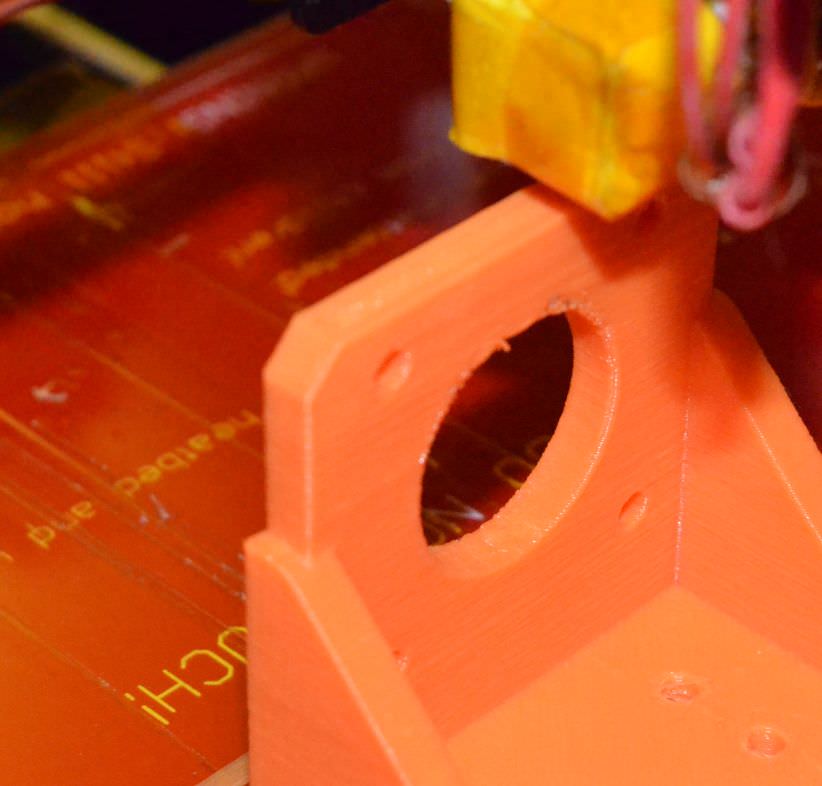

The brim have some bed adhesion issue, I can not tell if first layer have similar issue from the picture, you might want to try slow brim printing speed down. First layer and brim usually print at speed slower than 30mm/s, if you already printing slower than 30mm/s, try increase nozzle temperature or use more glue or hair spray.

Overall quality is not bad considering you just got everything working and have not include any mod yet. I definitely saw lots of worse print that people post on facebook happily came from their $500+ printer.

(Da Vinci 1.0, Jr. 1.0 RAMPS, miniMaker) X4, (Creality CR-10S, CR-10 mini, Ender-3) X4, Anycubic MEGA X4, Anycubic Chrion X1, ADMILAB Gantry X2 (MonoPrice Maker Select V2, Plus, Ultimate)X4--Select mini X1, Anycubic photon X4, Wanhao duplicate D7 X1.

iNSTONE Inventor Pro X2, CTC Dual X2, ANET-A8, Hictop 3DP-11, Solidoodle Press, FLSUN I3 2017X1