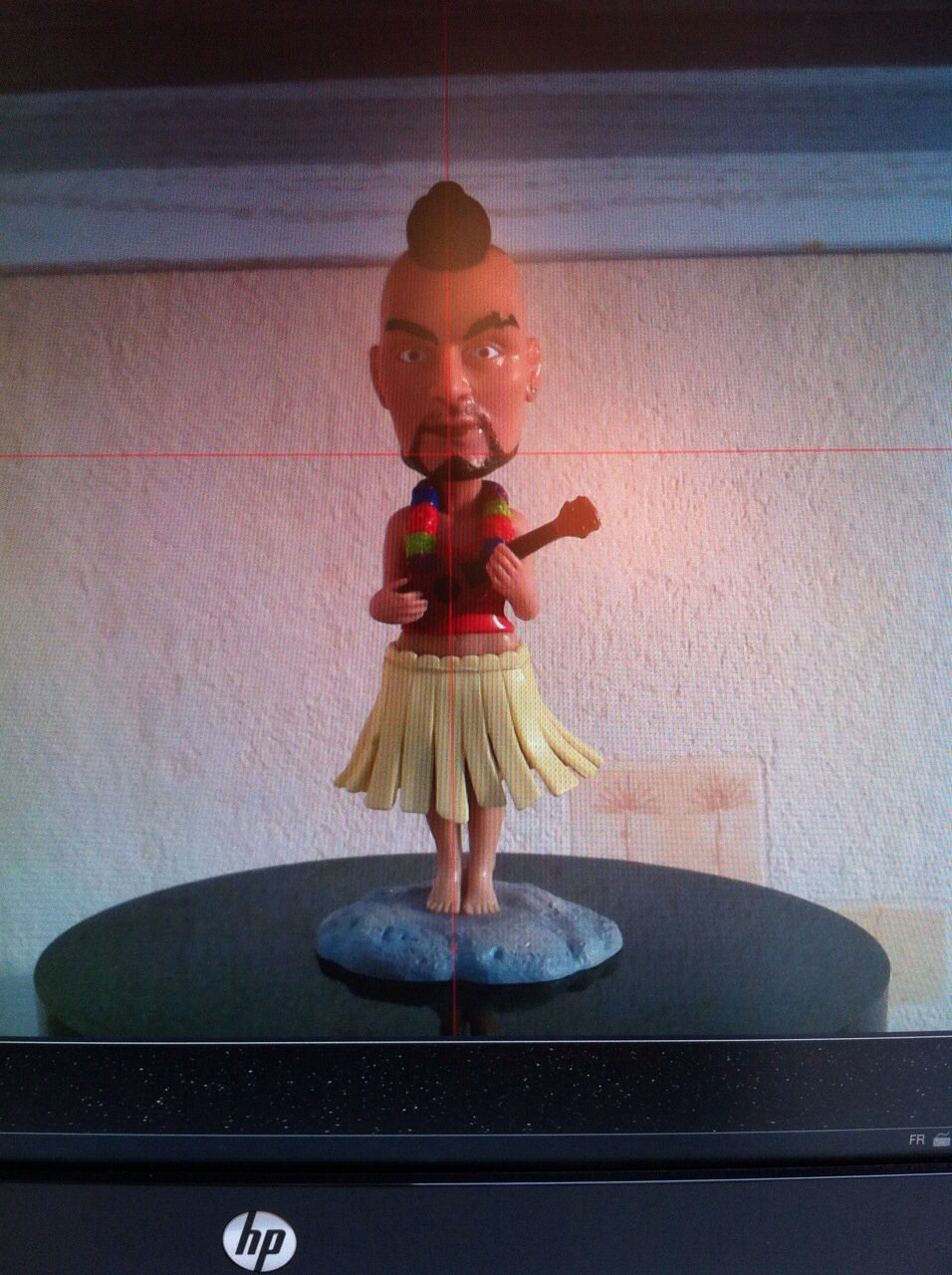

Hi! Thanks a lot for your feedback. Yes, my Vaas-vahiné has been used as a model for my Atlas 3D tests :-).

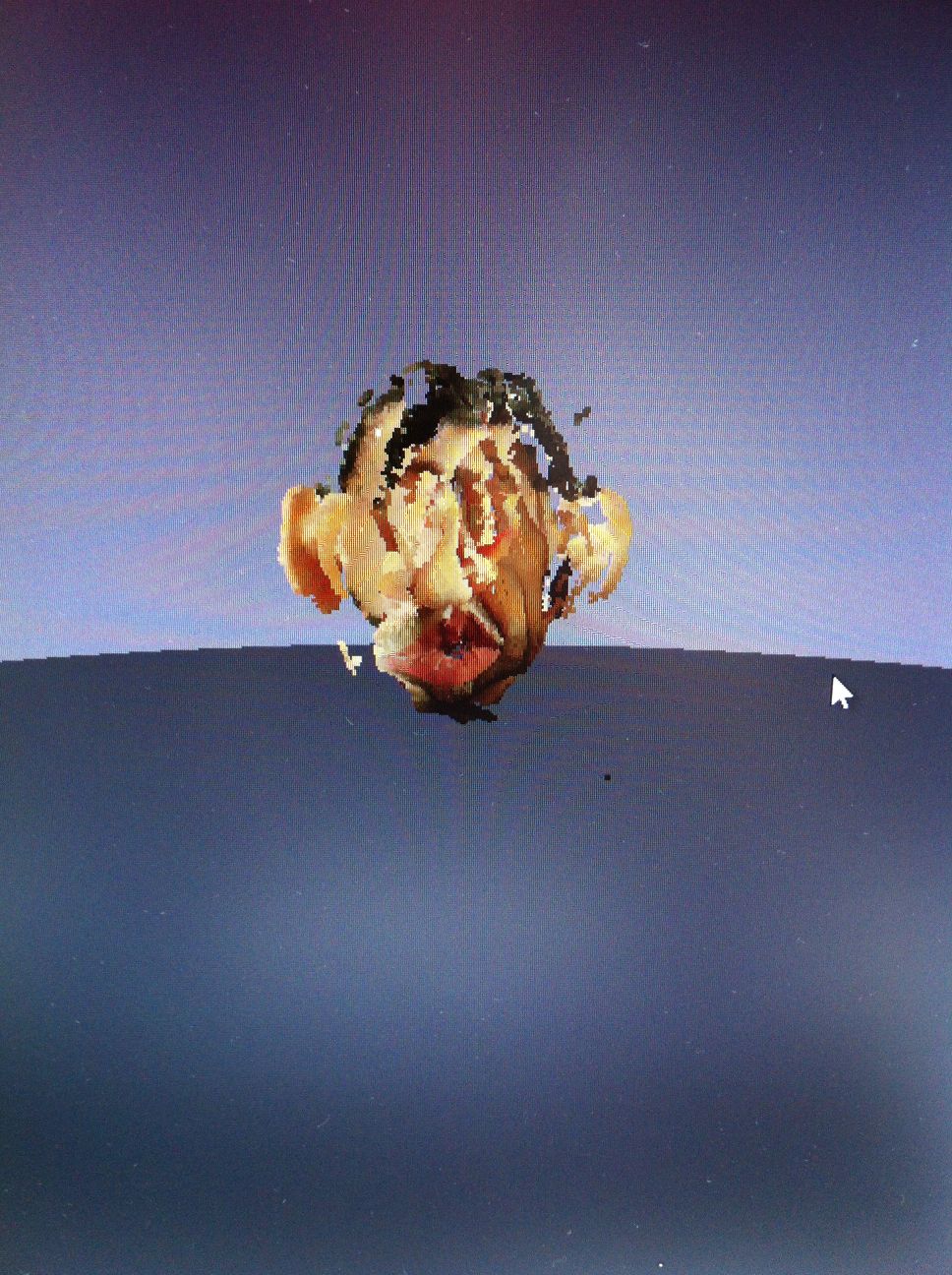

After your remarks and suggestions, I checked the global calibration, and after few tries, everything come to a correct scale again. Now I'm encountering other issues. Globally, the scan results are nice, but often too messy, and I don't understand why. I tried different situations (different light expositions, different backgrounds, only one laser, default resolution instead high, ...) and at the end, I'm not able to find a common mode.

For example, I tried to scan a Lego Omer:

With both lasers and with default resolution, I've got the folllowing result:

With only one laser, I got this:

When trying the high res and both lasers on those two models:

I respectively have the following results: blurry, unfinished and asymmetric:

The worst result is on the S. Gainsbourg head. I never succeeded to scan it properly. Never. Is it due to the fact that it is a bit too small? For the other models, sometimes it is correct, sometimes not. I also tried to push some more light on the model to scan, and I think it is worst than only natural daylight.

Just for info, and to give some context on my scans, I took some inspiration from this forum concerning the calibration and built this (used on top of the small printed device for camera calibration):

Also, for the correct superimposition of the two lasers, I'm checking it like this:

So, if I'm not wrong with the calibration (and I think I'm not), I'm then lost with the scanner parameterization and environment (mainly regarding the model exposition).

Does someone have some clues for me?