Topic: Crazy Z Suspension Carriage Concept (To Reduce Banding)

This banding issue has been bothering me. I know that Solidoodle are working on a fix, but I love trying to solve problems. I am a programmer by trade, so problem solving is all I do ![]()

My banding is very subtle, the Z-Nut fix has helped, but it still has some wobble. You can see my post talking about it here

So, I keep thinking to myself, there is quite a bit of play in the bed. The bushes against the Z rear rails have quite loose tolerances. So I setup a simple third rail guide rail, using the threads for the door hinges to hold some brackets. And designed an arm to screw to the bed:

It has taken some of the slack out, but with my laser pointer wall test, was still getting about the same amount of wobble. As it can still wobble at the rear due to the lead screw. This third rail has not restricted the extruder movement, and with a modified bottom bracket design, will not limit the bed movement either.

So my next thought has been, how can I decouple the X/Y plane from the lead screw. Some people have been using a universal joint between the stepper motor and the lead screw, but that doesn't fix a lead screw with a slight bow/bend.

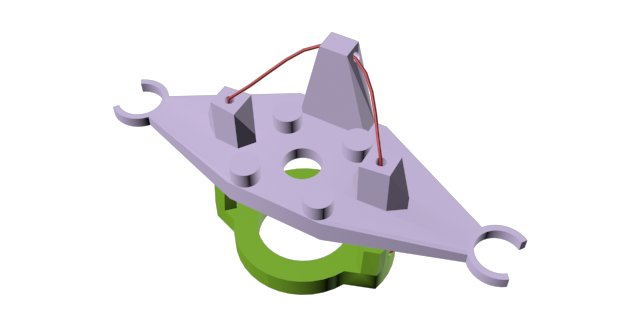

So I started to design myself this crazy contraption. It is designed to hang the bed off a couple of cables. So the lead screw can wobble the carriage, and the length of suspension wire should reduce the wobble seen by the bed. Here are some pictures of my concept:

The 4 pegs on top, are to make use of the 2 part Z Axis fix print.

The bottom eyelet piece, I am going to redesign to print on its side or at a 45 degree angle, to make better use of the grain of the print. To make it stronger along the points of stress.

Thoughts, opinions? Should I give it a go, am I being an idiot? It is all designed to allow me to go back to the standard setup of it doesn't work or help.