Topic: Re-using rafts?

Is it possible to print a part on a raft you have already use for another piece? Has anyone done this?

My Blog http://ggalisky.weebly.com/

My Youtube https://www.youtube.com/channel/UCXShYo … aDUpebDAOw

You are not logged in. Please login or register.

SoliForum - 3D Printing Community → Solidoodle Discussion → Re-using rafts?

Is it possible to print a part on a raft you have already use for another piece? Has anyone done this?

Probably not since the raft comes off the bed with the part often before the part is removed from the raft. Additionally, a raft uses so little plastic that it really won't save you much time or money. I personally prefer to print without a raft. I feel that it actually makes my prints stick to the bed worse.

I have been thinking about reusing rafts. I have some jobs where I do 1000 of the same thing over and over again. The bottom surface finish is critical to the customer. (The part actually gets sealed in a metal container with the bottom side down, screwed to the bottom of the metal container and then never looked at again ever, ever.). I tried to convince customer that the bottom will never be seen but they needed perfect parts for quality control. I have had to get creative with build surfaces because absolutely any imperfection shows up. I use Buildtak as a surface on a Taz 4 Lulzbot now, but I am always looking for one more tweak. I have a (functional, running) Makerbot 5th gen, that makes the best rafts you've ever seen. I think that under the right circumstances a 3d printed raft could be used more than once.

The big advantage for a printed raft is the surface finish on the bottom of the finished part, followed by the leveling effect, its like grinding (resurfacing) a grinding table in the machine trades.

In theory, you could just print it once with the once with the raft, remove the part only, then reslice it without the raft in the exact same space. You would have to add something to the G code to raise the head/ lower the bed for it to initially clear the raft, but it works in theory.

In practice, there is so little to be gained from this you and so much that could go wrong, it will probably always be easier to just print another raft.

Personally, I HATE using a raft for anything. If my printer required it to get good adhesion, I would junk the machine and get another. I had one customer who wanted a figurine that required a large raft due to a small footprint. I jacked the price and refused to remove the raft myself for fear of breaking the part, which had very thin sections.

I have a Makerbot Gen 5 and I am finding I cannot print without rafts. In one case I have a very short part with a very large footprint. As a result with the default raft settings I end up with about 40% raft so between time and wasted plastic it would really help to be able to reuse it since I have at least 8 of these parts to make.

As for the comment about throwing away the printer, anyone with that recommendation please send me the perfect printer and the money to buy it! ![]()

It would seem you either need a slicer that can handle it or a program that could much with the resulting file to raise the print a little.

I do wonder if the advantage you get from the first print would transfer to subsequent prints. If so why doesn't somone come up with a new build plate made from PLA? Or something you could tape to the build plate?

Just use hairspray on a glass plate and all adhesion problems will go away. It's the new standard.

Just use hairspray on a glass plate and all adhesion problems will go away. It's the new standard.

+1

I have a Makerbot Gen 5 and I am finding I cannot print without rafts. In one case I have a very short part with a very large footprint. As a result with the default raft settings I end up with about 40% raft so between time and wasted plastic it would really help to be able to reuse it since I have at least 8 of these parts to make.

Have you tried printing without the raft? Why are you forced to use a raft?

The school I work at has a 5th gen Makerbot Mini and the one of the first things we did was turn those ridiculous raft settings off. Make sure your bed is level though, on our Mini there is no way to adjust the bed other than the z offset, so we had to print a support plate the helps keep the bed in place.

carl_m1968 wrote:Just use hairspray on a glass plate and all adhesion problems will go away. It's the new standard.

+1

I looked up a UTube video and it seems like you need a heated build platform for it to work. My unit does not have a heated platform.

The guy also used a ton of hairspray. Here is the link see what you think:

He is using too much.. They sell a conversion kit to put a heated bed on that machine.. Otherwise you will only be limited to PLA as nothing else will print on a non heated bed..

If you can't heat the bed then the best you can do is blue painters tape and make sure the bed is adjusted so that you can just get a .15mm feeler gauge between the nozzle and bed surface. Not usre if there is a leveling function but you might want to see if you can do it manually as most built in functions are not accurate.

I just tried an experiment. I printed a part with a raft and removed it and left the raft although part of the raft did lift during removal so I taped it to the plate. I raised the part by the thickness of the raft (1.75 mm). I then tried to print without a raft. The first problem was when the printer tried to calibrate at the beginning by pushing the extruder down in the center of the build plate it melted the raft so that did not work. So I took a .001 feeler gauge and put that in the center. that is like .11 mm so I raised the z axis by .1 mm. I then printed. After the printer calibrated the extruder I removed the feeler gauge and let it print. It almost worked the problem was the filament did not stick to the raft in the middle of the part so it was causing "tents. Not bad for a first try almost worked. Might be worth some more attempts with adjusting things slightly. Also I was printing with .3 layer height which might have been to thick.

which might have been to thick.

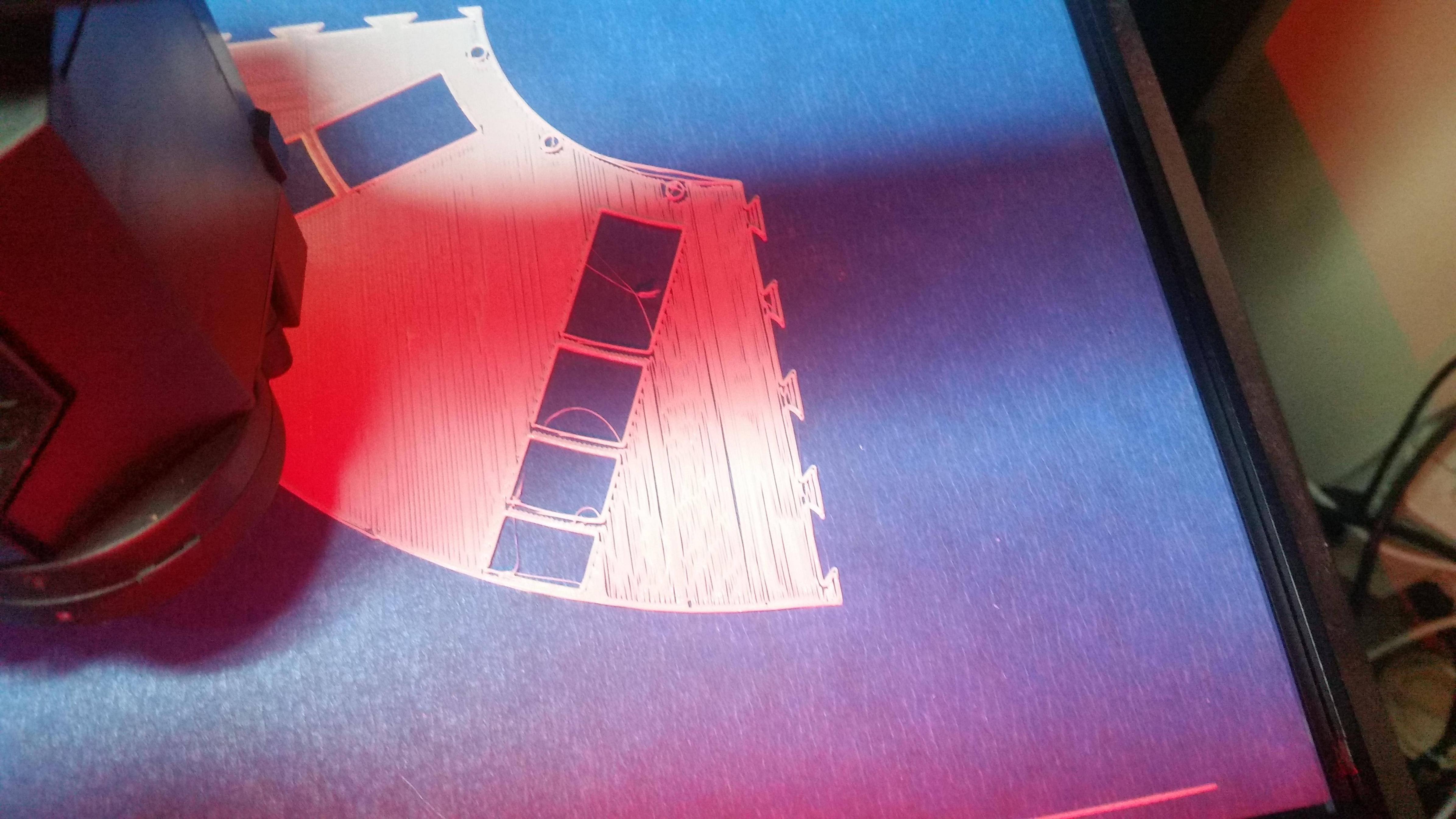

Here is a picture of the raft and the part. Most of the part was removed to see how easy it would separate. If you look at the removed piece you can see the problem. Also on the raft you can see the hole made by the extruder the first time i tried to print and failed on the calibrate.

Here is a picture of the raft and the part. Most of the part was removed to see how easy it would separate. If you look at the removed piece you can see the problem. Also on the raft you can see the hole made by the extruder the first time i tried to print and failed on the calibrate. Here is the underside of the part

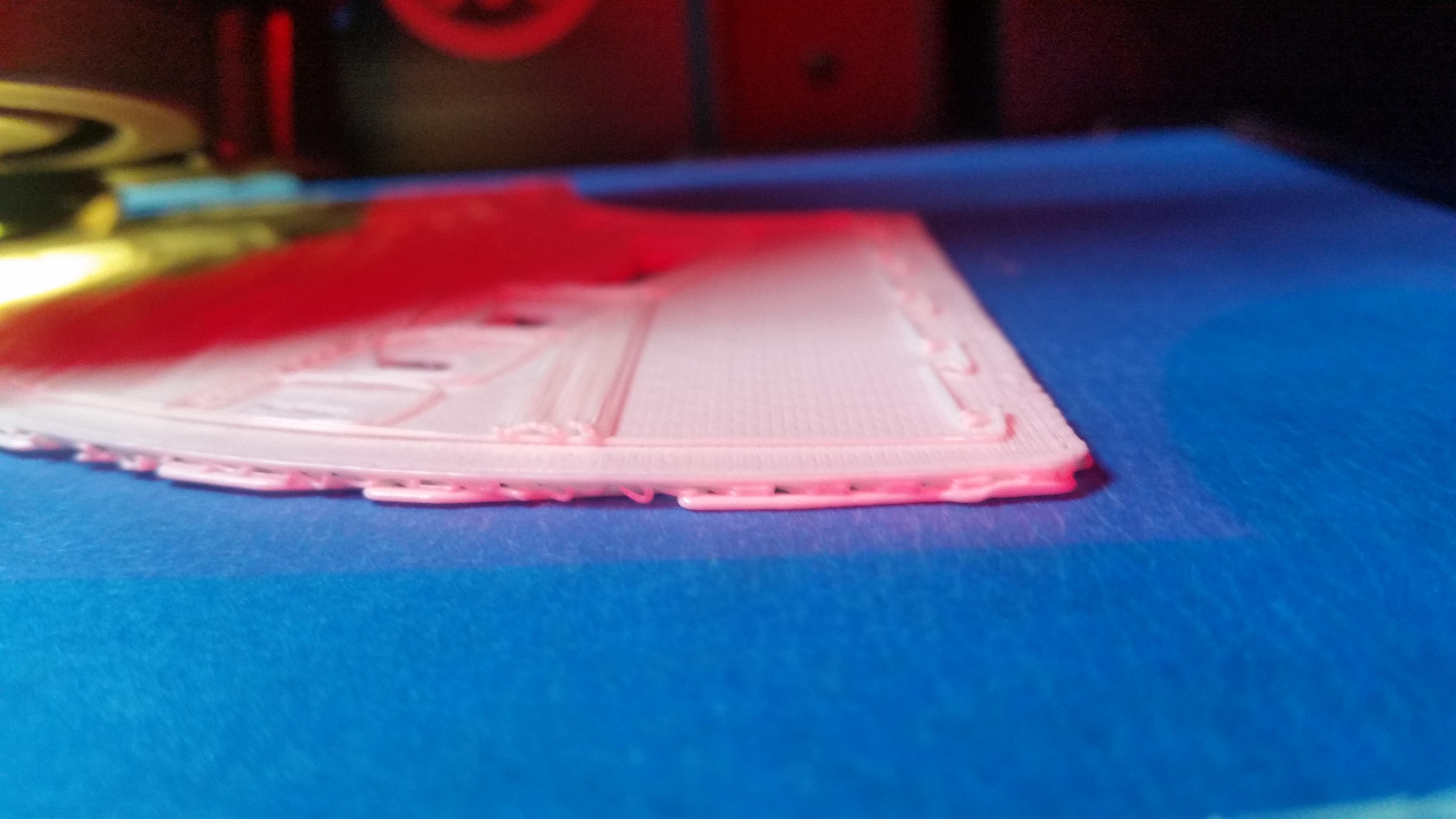

Here is the underside of the part

The issue is the raft has cooled too much to get a bond on the newly printed layer. Although your bed is not heated the raft when printed stays hot enough for the next layer to bond. You cant lay hot plastic on cold plastic. Another trick you could try to get away from rafts would be putting Elmers purple glue stick on the area to be printed in on the purple tape. As long as the object stay warm the tape and glue should hold it down.

I was concerned about the cooling but I thought because you can stop and restart a print you it might work. Obviously it did not. I actually did not want the plastic to stick too good because then the raft would be come part of the part. ![]()

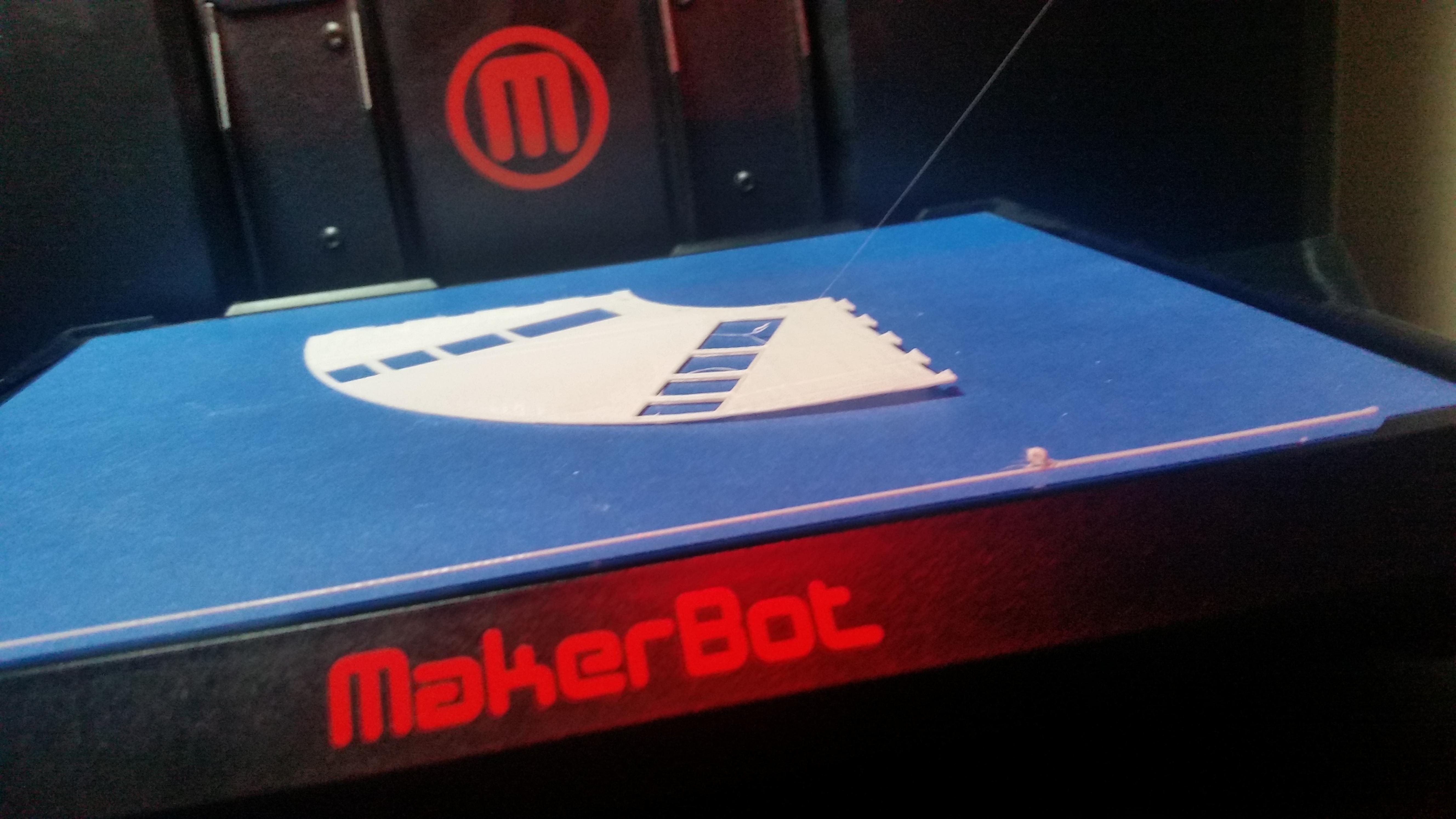

I just releveld again and now I am trying without a raft and with the z axis decreased by .1. Last time I tried this the extruder clogged and did not put any plastic down in one spot of the print. This time it seems to be working much better. The only negative is that when the extruder first started to print some of the square frames the first pass did not stick but the second one did. So for my purposes as long as the rest works, and it looks good so far, and as long as there is no curling I may be ok without the raft.

Here are two pictures with the first layer almost done (1st) and done (2nd). Notice how the layer is smoshed a little on the left and gets sloppy on the right. Not great but acceptable for a filament spool.

Just as I was uploading the last picture the part started to curl. As you can see in the following picture:

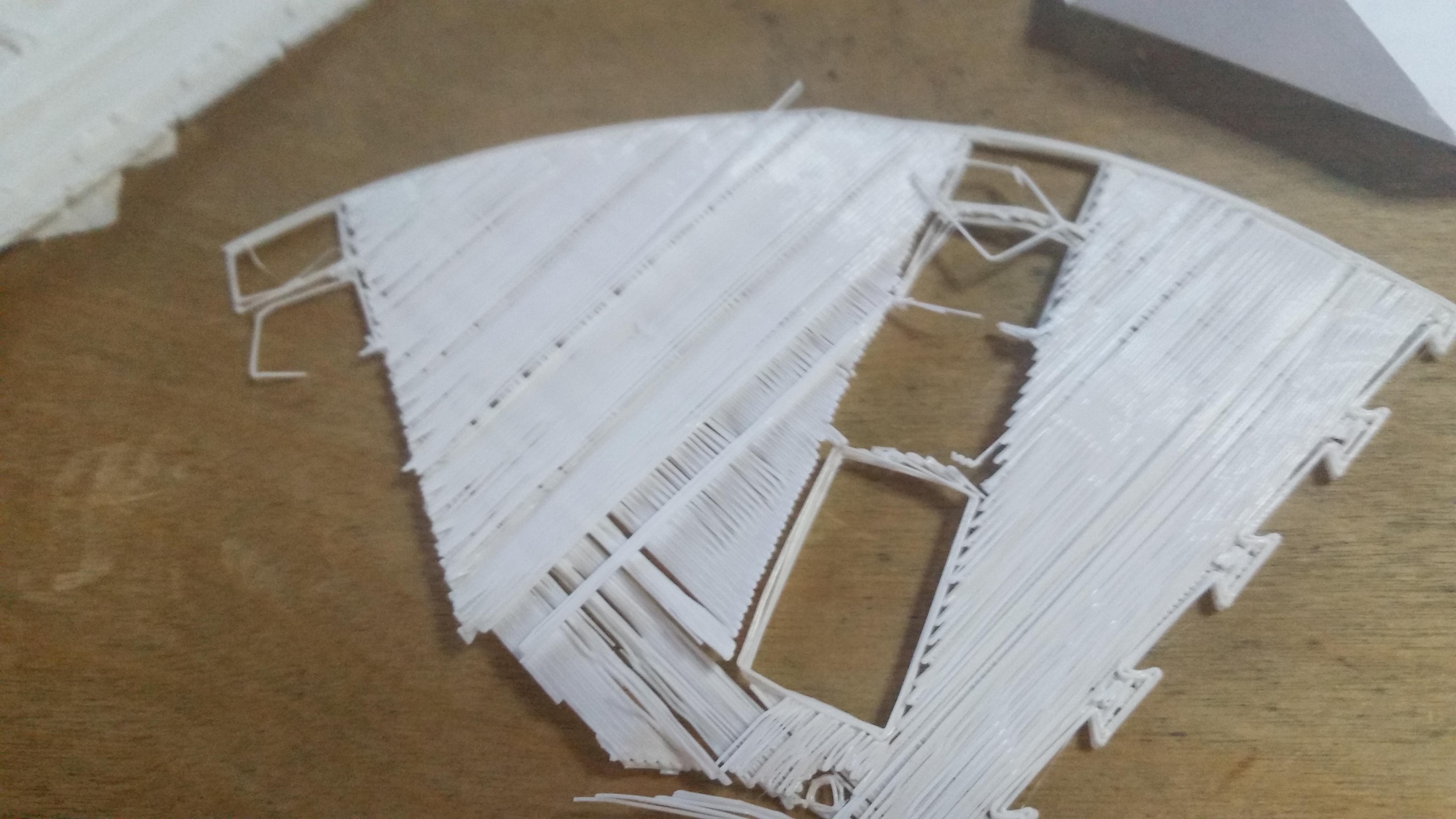

Lastly you can see in the following picture two parts, the top is the one just removed from the printer, the bottom was one printed with a raft. The top one is has a better quality surface so you not only loose time and plastic with rafts you also loose quality:

It is not surprising the Makerbot push you hard to use rafts.

The issue is the raft has cooled too much to get a bond on the newly printed layer. Although your bed is not heated the raft when printed stays hot enough for the next layer to bond. You cant lay hot plastic on cold plastic. Another trick you could try to get away from rafts would be putting Elmers purple glue stick on the area to be printed in on the purple tape. As long as the object stay warm the tape and glue should hold it down.

I assume by purple tape you are referring to blue painters tape?

BTW I had BuildTak on the printer before and so far the blue tape seems to be performing better.

I meant blue tape with Elmers purple glue stick on top of the tape.

SoliForum - 3D Printing Community → Solidoodle Discussion → Re-using rafts?

Powered by PunBB, supported by Informer Technologies, Inc.