Topic: Free PSU upgrade (for computer nerds)

So my setup has always been slow, never quite figured out what it was, but the power supply always struggled too.

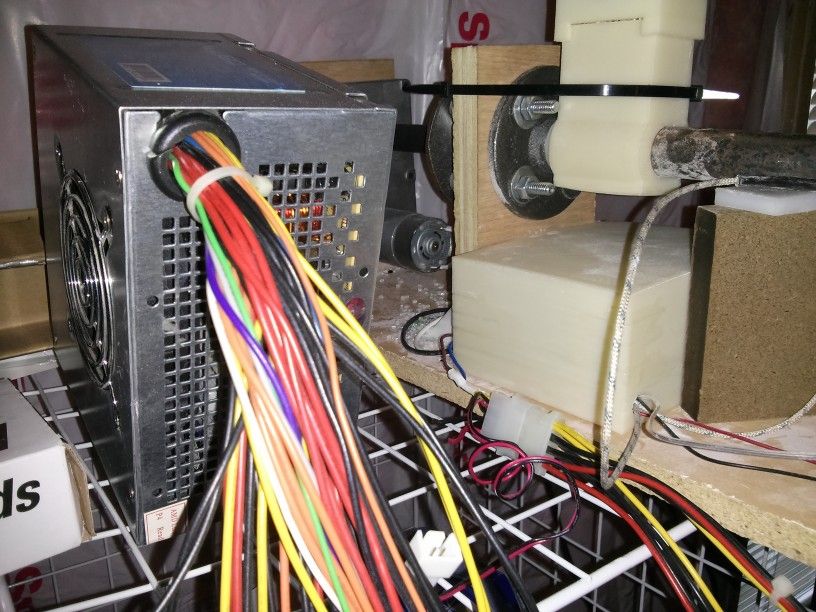

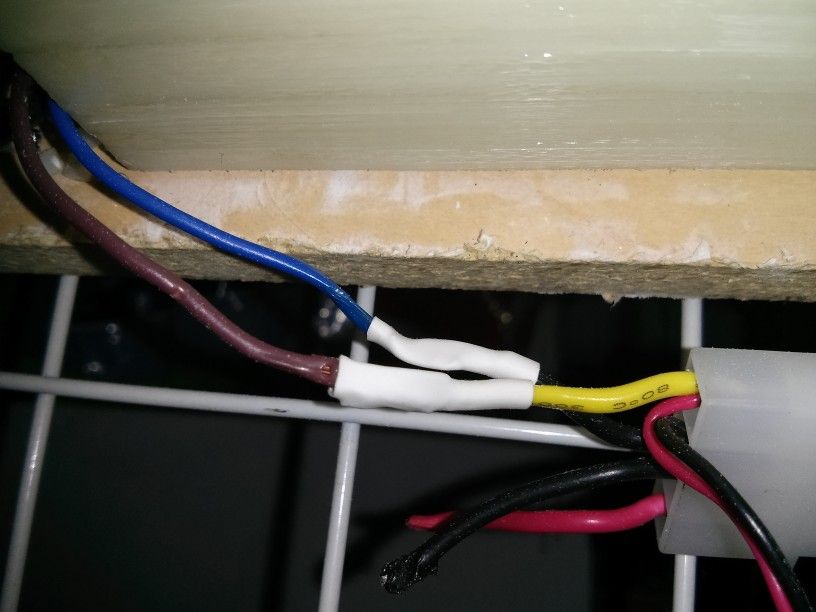

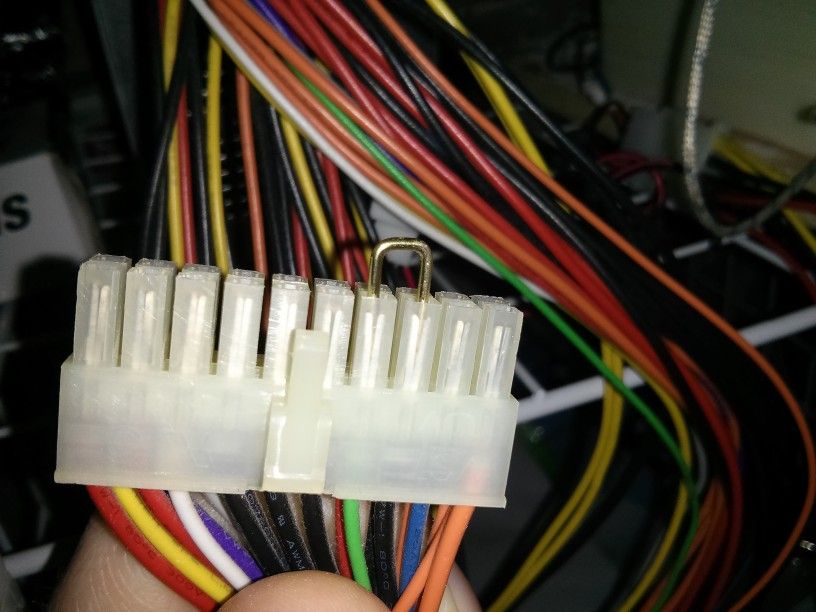

The provided one appeared to be under heavy load and the motor current would spike when heater shut off for a second. Always annoyed me with it spiking around, so I pulled out an old computer PSU. For those of us with old PCs sitting around, this is a simple upgrade. I cut out the original 12 V supplied wires and spliced them into a yellow 12V line on a computer power pass thru cable. The green line had to be shorted so the PSU turns on. Really simple if you have good solder skills, but for me it took a bit. Probably could get away with crimp connectors too. Figured this would be common, but I didn't see too many others post it.

My basic now 12 year old PSU does 17A on the 12V line, which is plenty of current.

Cooling fan would have been a lot easier to hook up if I started this way. Might cool to make optional connectors for PSUs in the kit over taking the laptop style power supply.