for spare parts printing.

the carriage assembly doesn't appear to be under a lot of stress, it would be strange is it broke, besides which other posts have suggestted that the X axis is glued in place, so it's not really a serviceable item.

There is a post elsewhere that suggests that the white bearing blocks may wear, but with proper greasing this shouldn't happen.

the hot end. and bed heater.

to be honest I think it's probably easier to keep a roll of nichrome wire and kapton on hand, if the hot end breaks it's possible to re-wire and re wrap it with a small section of a $2 roll of nichrome and a even smaller percentage of a $3 roll of kapton tape.

the time taken to rebuild the hot end (completely replacing the heating element is surprisingly short.).

if you needed to replace the bed heater resistor.

you could replace with another 3ohm wire would resistor. (which given the design deficiencies thread looks like it's not the best part for the job)

or again you could use a roll of nichrome wire.

insulate the bottom of the bed with some kapton, then stretch a length of nichrome that's 3ohms in a square or spiral to cover more of the bed and get more even heating.

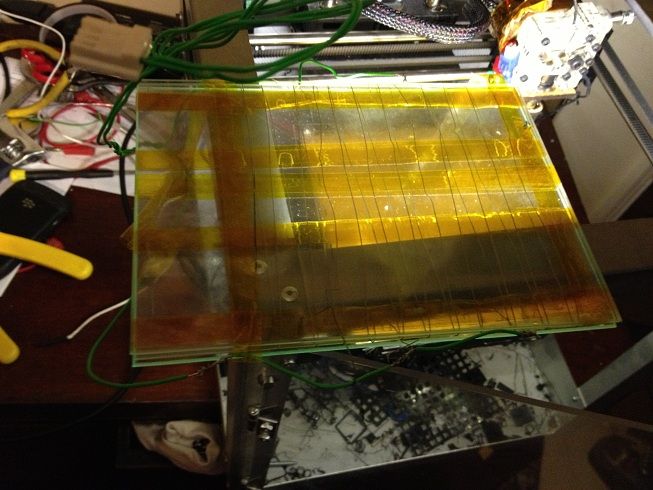

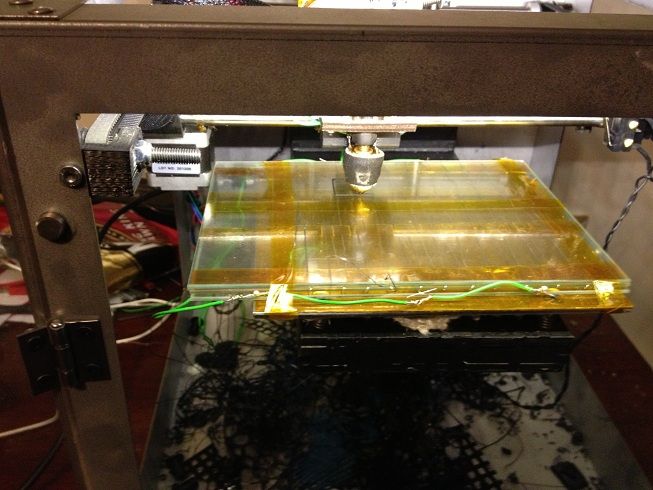

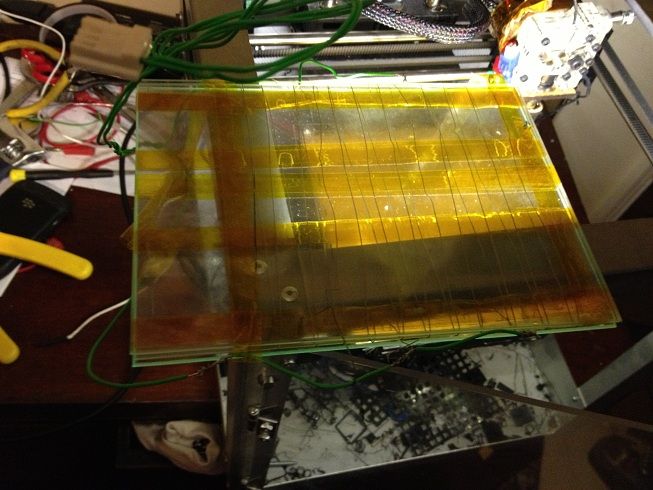

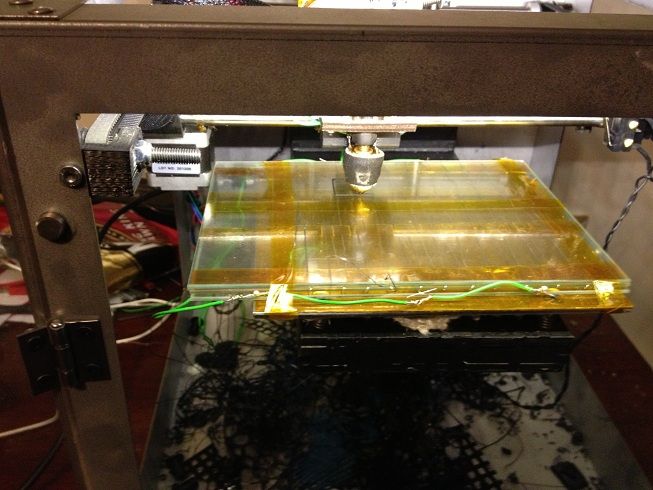

this test bed is a sheet of glass wrapped in nichrome wire, (3 9ohm pieces wired in parallel).

a sheet of glass on the bottom and a sheet of glass on the top.

it's about 6mm thick in total (so you don't need to replace the Z screw.)

it heats the entire bed evenly, and the top layer of glass is at printing temperature in between 1 - 2 minutes.

plugs straight into the existing electronics... took about 3 minutes to make, cost me a pack of three ikea clip frames, and about 1/2 of a 5m roll of 28AWG nichrome. (a thinner wire would use less wire)

my point is sure, you could get spare parts.

but a better idea might be to plan the obsolescence of parts.

then rather than being a pain, that bed resistor dying is a call for a nice upgrade.

I'd print a new extruder to replace the jigsaw extruder,

because the acrylic is prone to cracking, and it's a pain to work with anyway - so again when it does break it's actually just a nice excuse to swap for a better part.