solidoodlesupport wrote:IanJohnson wrote:I wonder if this might be the problem - I found this in an ebay listing for a Sanguinololu

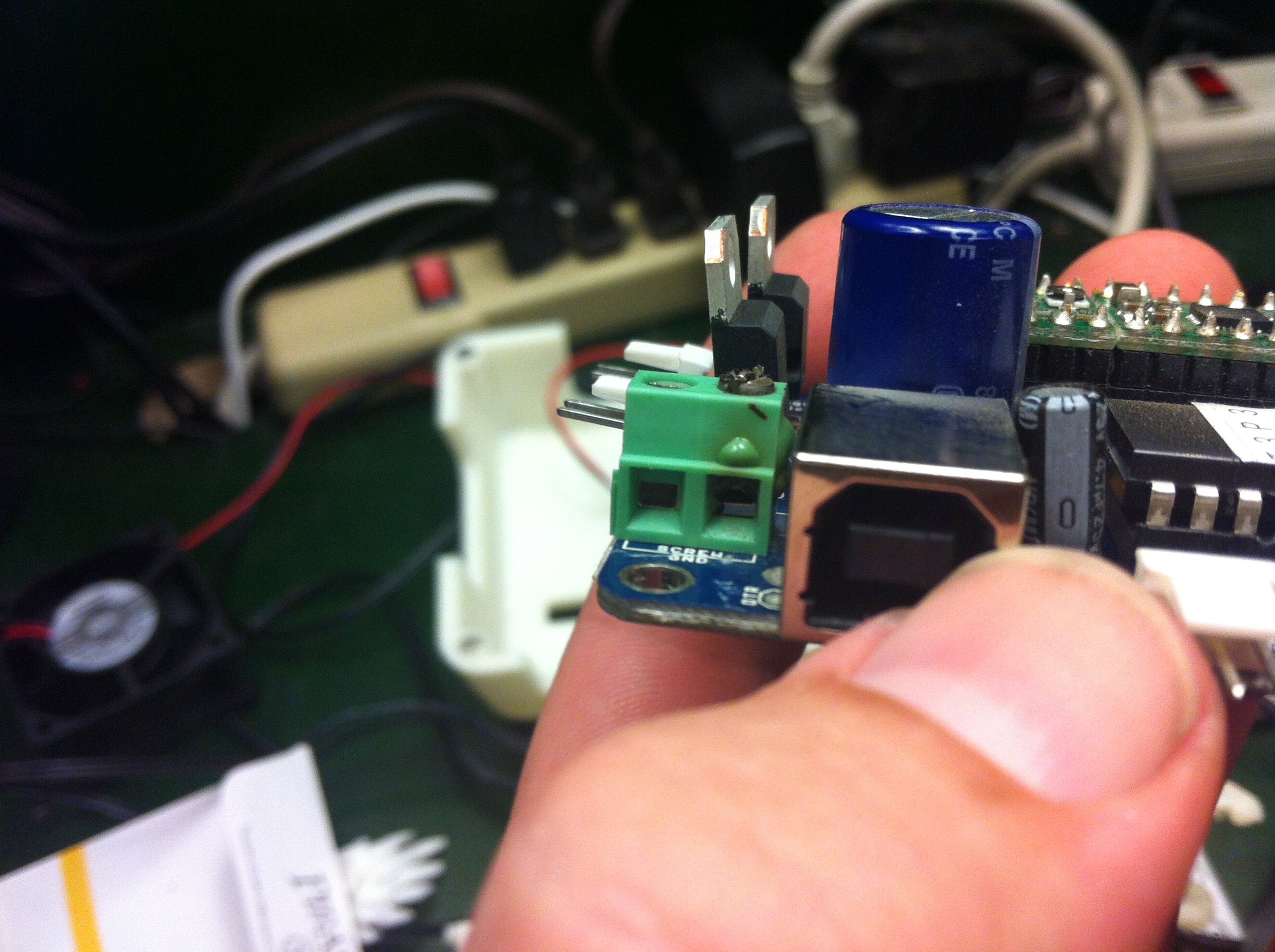

PLEASE NOTE The Sanguinololu design is excellent but if you are going to run a heat bed the traces on the Sanguinololu board are NOT sufficient to carry the current required to operate the heat bed. Jumper wires need to be soldered on the bottom of the board. If these jumpers are not there your screw terminal will heat up enough to melt. If you would like these jumpers installed before shipping let me know and I will add them for you FREE OF CHARGE.. here is a link to the information http://create3d.com.au/sanguinololu-ass … nforcement. If you purchase this board from me or elsewhere these jumpers will be required to run a heat bed.t

This is truly disturbing. We shall look into this.

Regards,

John

a few months ago now I made a post on the google groups that there was an issue with the sanginololo electronics.

I link to some posts by nophead in the reprap forums.

I was going to put a link to that post here but I really can't seem to find it.

no matter what my search times, even if I search for all posts made by me, I can't find it.

can't seem to find it now. (actually, it's a bit frustrating that a post, (especially a post saying keep an eye on your machines as the electronics are confirmed as underspeced and possibly dangerous) -has just vanished.

Anyway.

As said above, it's a well known issue, neither traces nor connectors are substantial enough.

An idea to improve the electrical safety of the machines would be to point to point solder a wire between the spurce pin and the bed plug such that the board (and it's under-spec'd trace) is bypassed completely.

or connect a relay to the bed heater control and have a power relay switch the power directly.