IanJohnson wrote:Find a pipe that can fit over the threaded rod, and is shorter. Put a large washer over the top of the rod, resting on top of the pipe. Thread a 5/18 nut over the rod. As you tighten the nut it will bottom out on the washer, and since it can't go down any more, it will start pulling the rod up.

You are going to want to use 2 addition nuts on the top of the rod jammed together that you will put a wrench on the keep the rod from spinning while tightening the nut on the pipe. Or if you don't care about the threads on the rod, a set of vise grips will do the same thing.

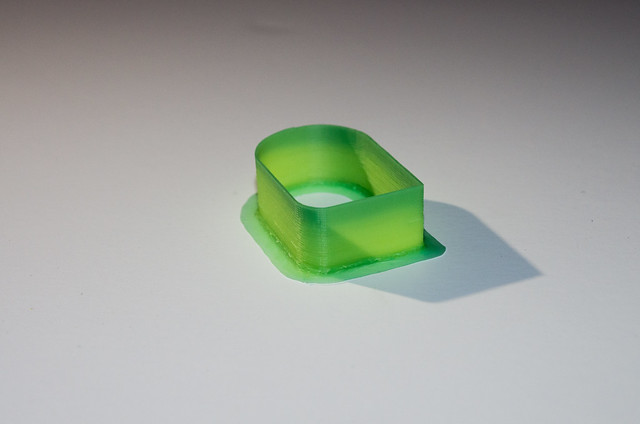

This is what my pictures are attempting to show. I just happen to have a tool that encapsulates a 5/16" nut. Same concept. Per usual Ian is able to explain it in a much simpler way.

SD3 w/ mods:

Glass bed with QU-BD heat pad upgrade, threadless ballscrew w/ 8mm smooth rod, spectra line belt replacement, lawsy MK5 extruder, Lawsy replacement carriage, E3D hotend, Ramps 1.4 w/ reprap discount controller, DRV8825 drivers, 12v 30A PS, Acrylic case, Overkill Y-idlers, Filament alarm, Extruder fan + more.