Topic: Veracity PETG Problems

I really wanted this filament to work but I am running in to problems with layer adhesion. Right now my current setup is an Anycubic Chiron with a few upgrades to the stepper motor drivers but nothing earth shattering.

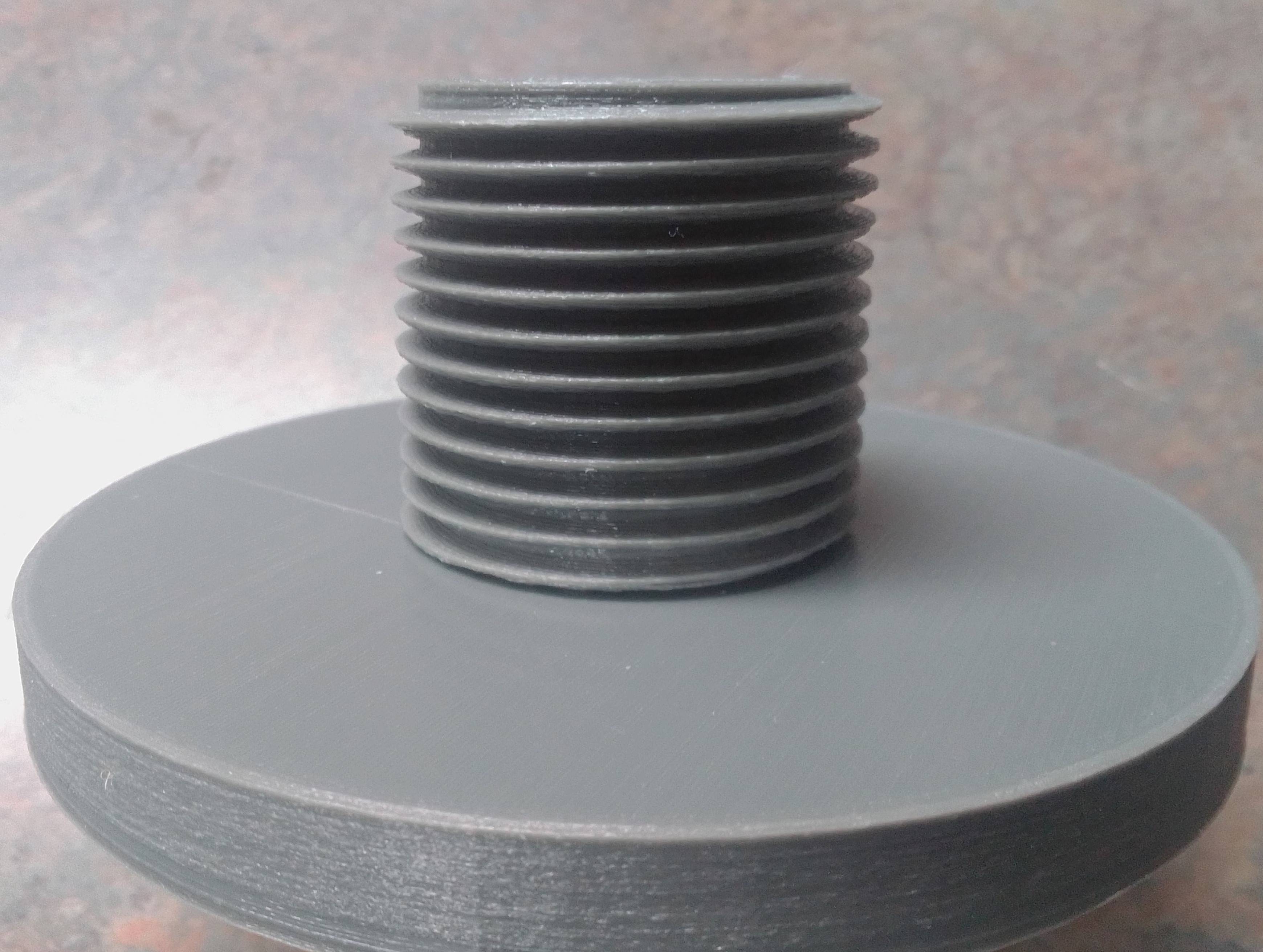

I bought some Veracity PETG and have been trying to make threaded parts. Layers are not all sticking to each other and I have tried slowing it down and running at about 260 degrees. It seems that it is outer edges that are really affected.

I am using the latest Cura as a slicer.

Thanks for any help.