Topic: Mini w+ Failing to print

Hi folkss

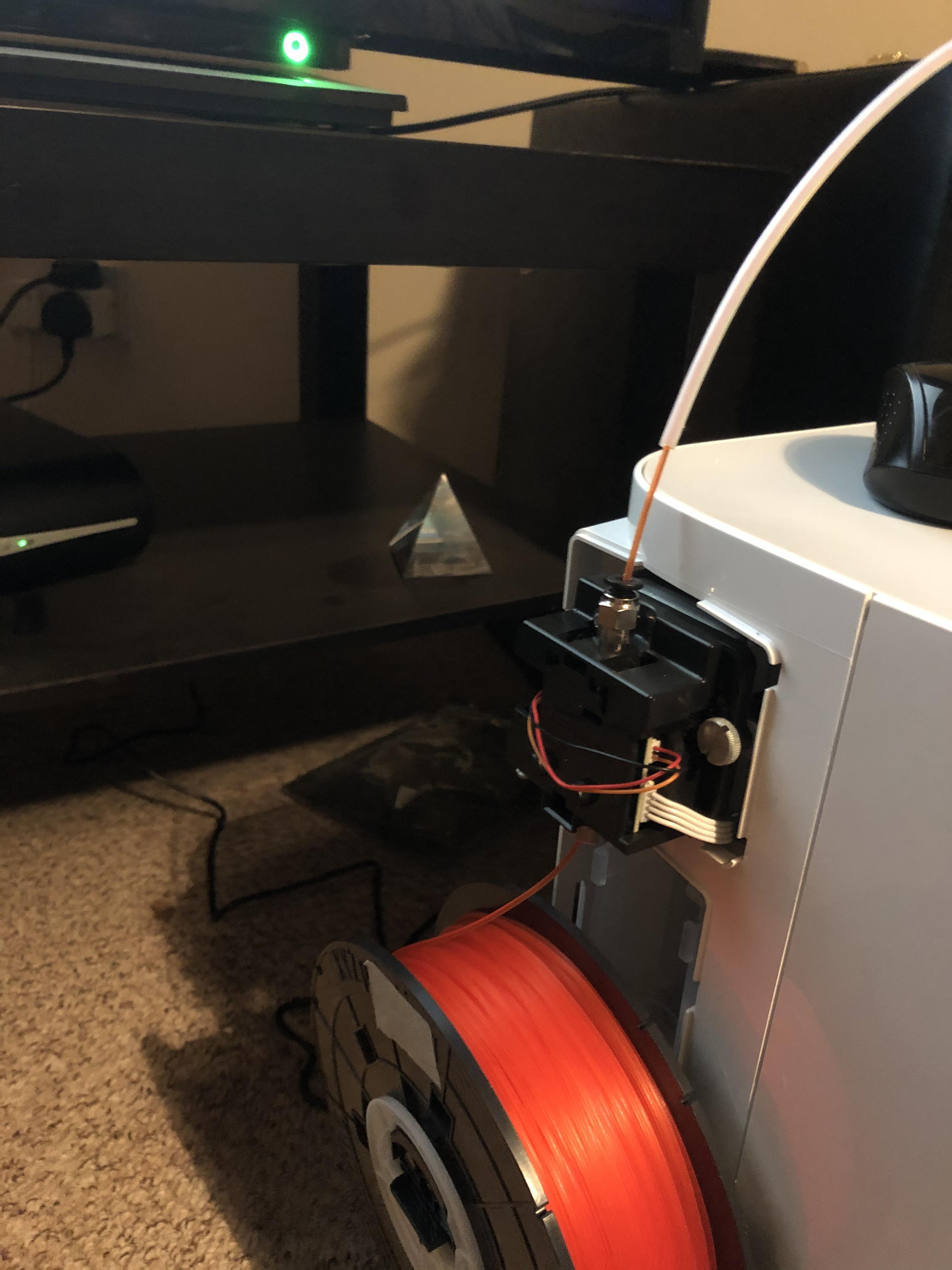

So I purchased a mini w+ and I have been using it to print PPE quite happily for around 22 hours of printing. Now it craps out within about 15 seconds of initiating a print. The problem is the guide tube detaches itself from the feed module, see pic below. This happens no matter how firmly I fit the guide tube. I thought maybe it was because the nozzle in the extruder module was blocked but I’ve cleaned it several times yet the problem occurs almost immediately on the first print run. Could it be a prob with the filament? It’s brand new straight out of the vacuum packaging. I need to get this back online so I can continue to donate PPE so any help would be much appreciated.

Stay safe everyone

Phil