Topic: stuck @ 10 mm/s max printing speed

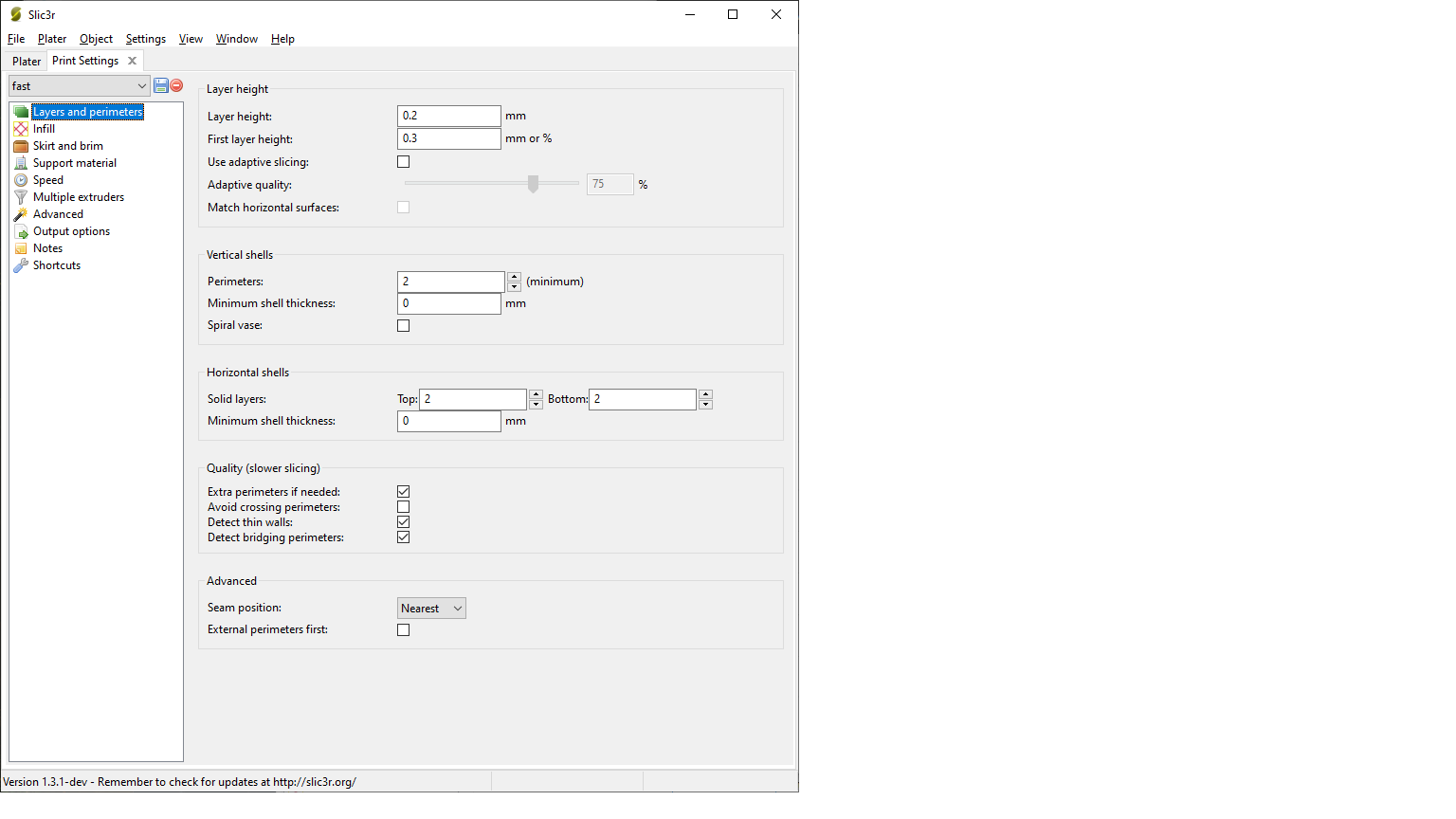

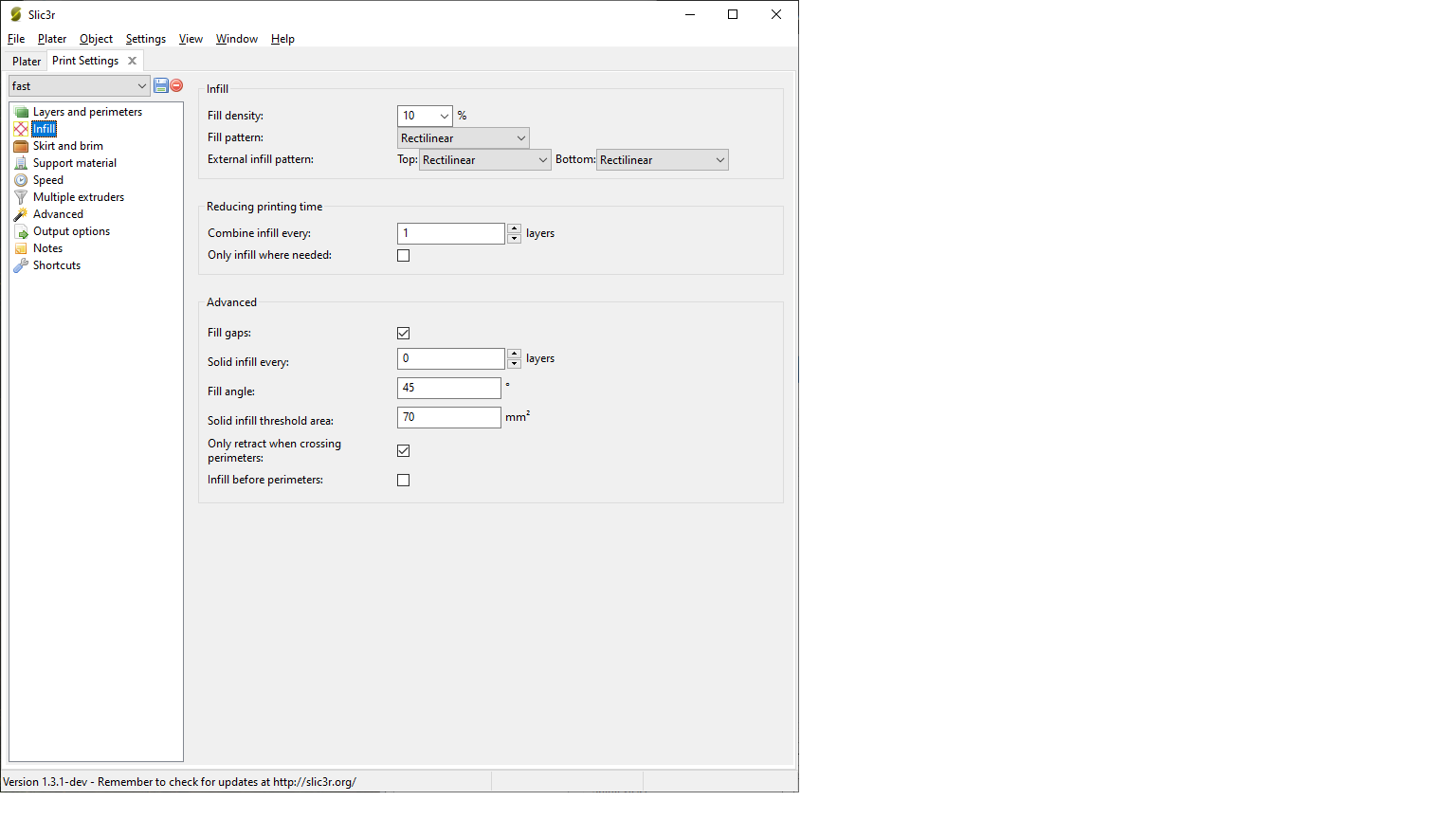

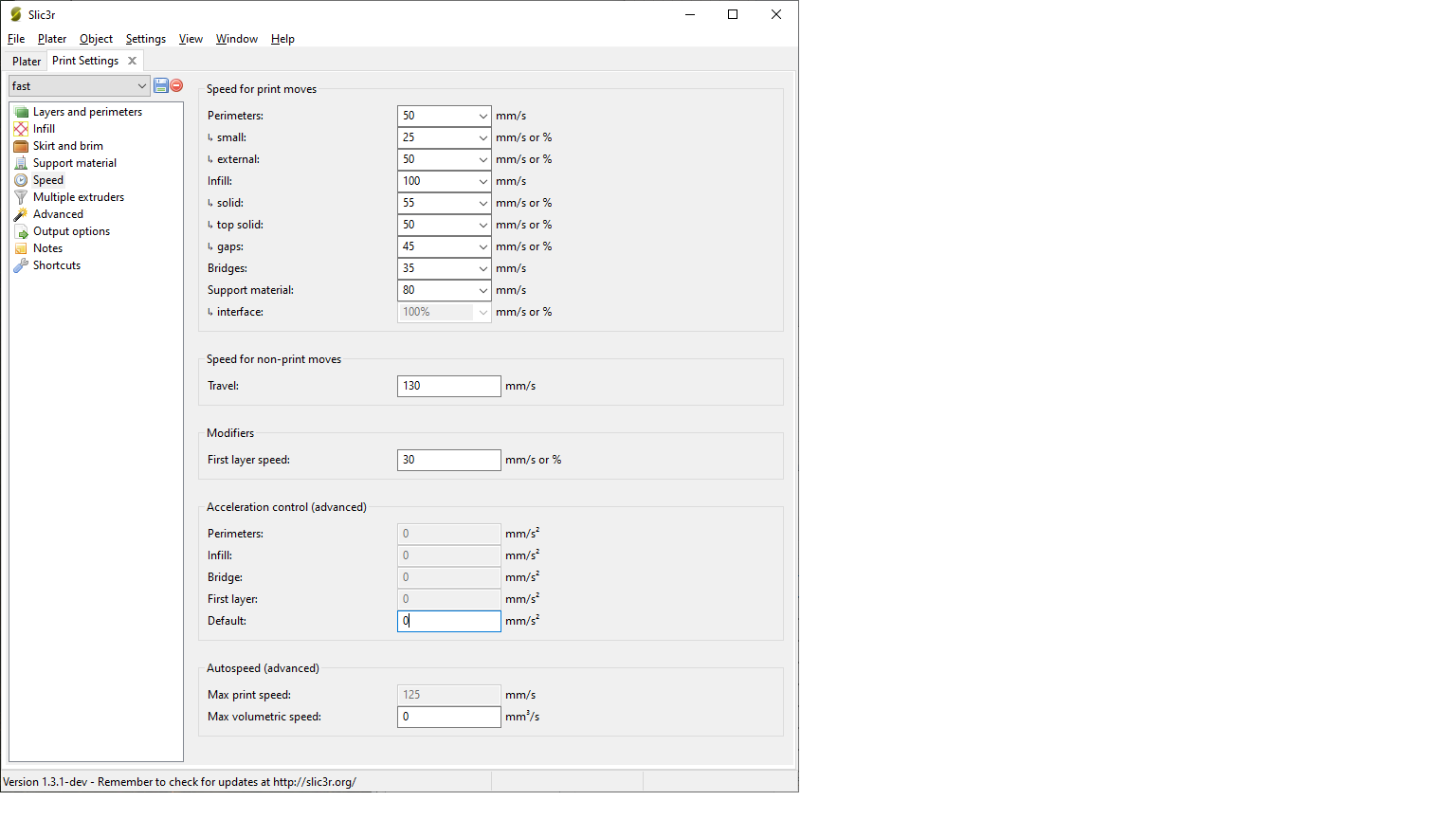

i was printing all day yesterday and now i must have done something that now my gcode is stuck at 10 mm/s perimeter speed.. i tried both slic3r and cura with same results with perimeter speeds set @ 60 but when i put gcode in "gcodeviewer" it shows 10mm/s

using solidoodle 3 with repetier

Edit: first object was a single wall hollow box for calibration;

now if i try to slice it as a solid box with 10% infill, the perimeters print normal speeds but NOW infill gets stuck at 10 mm/s