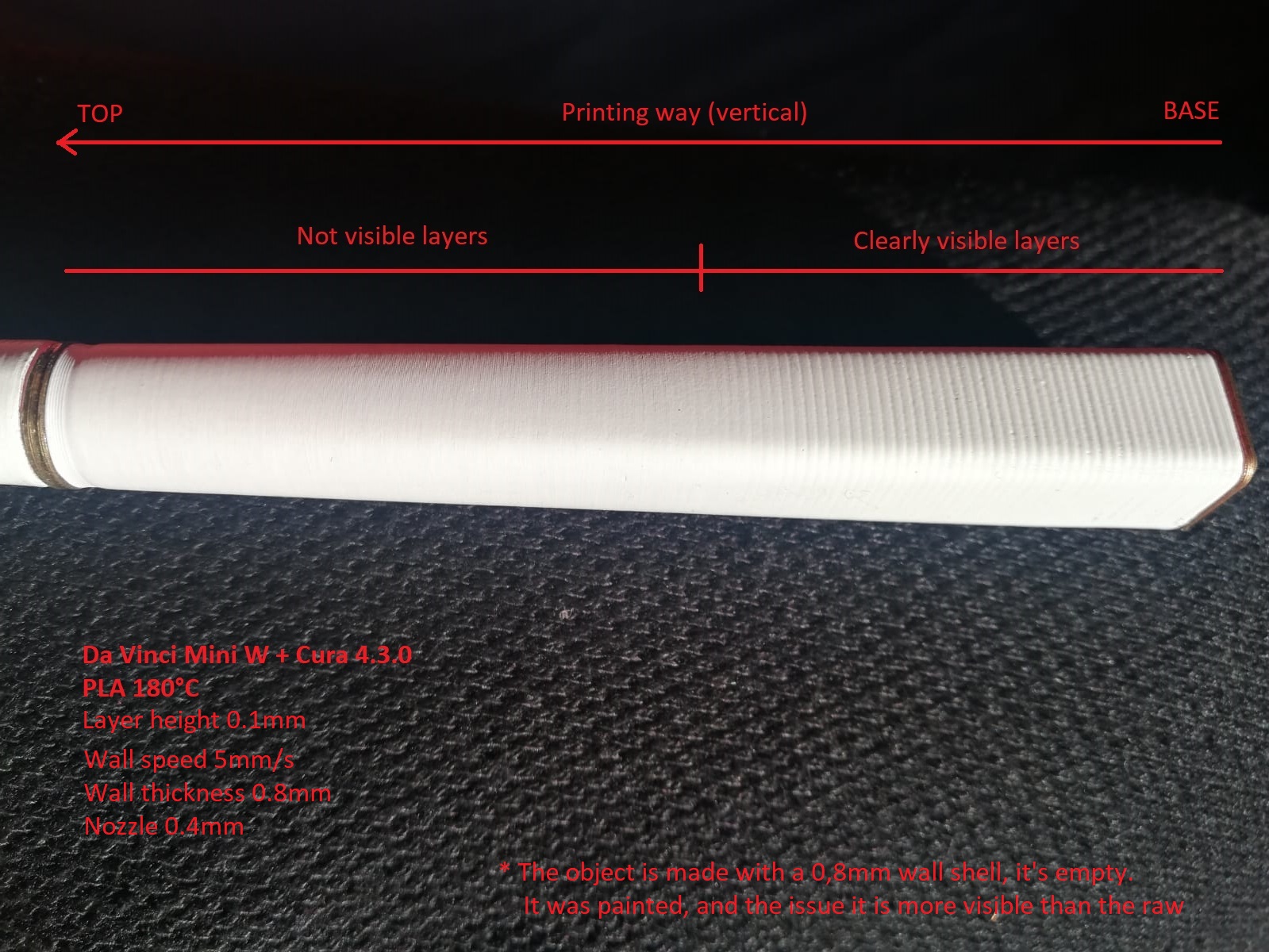

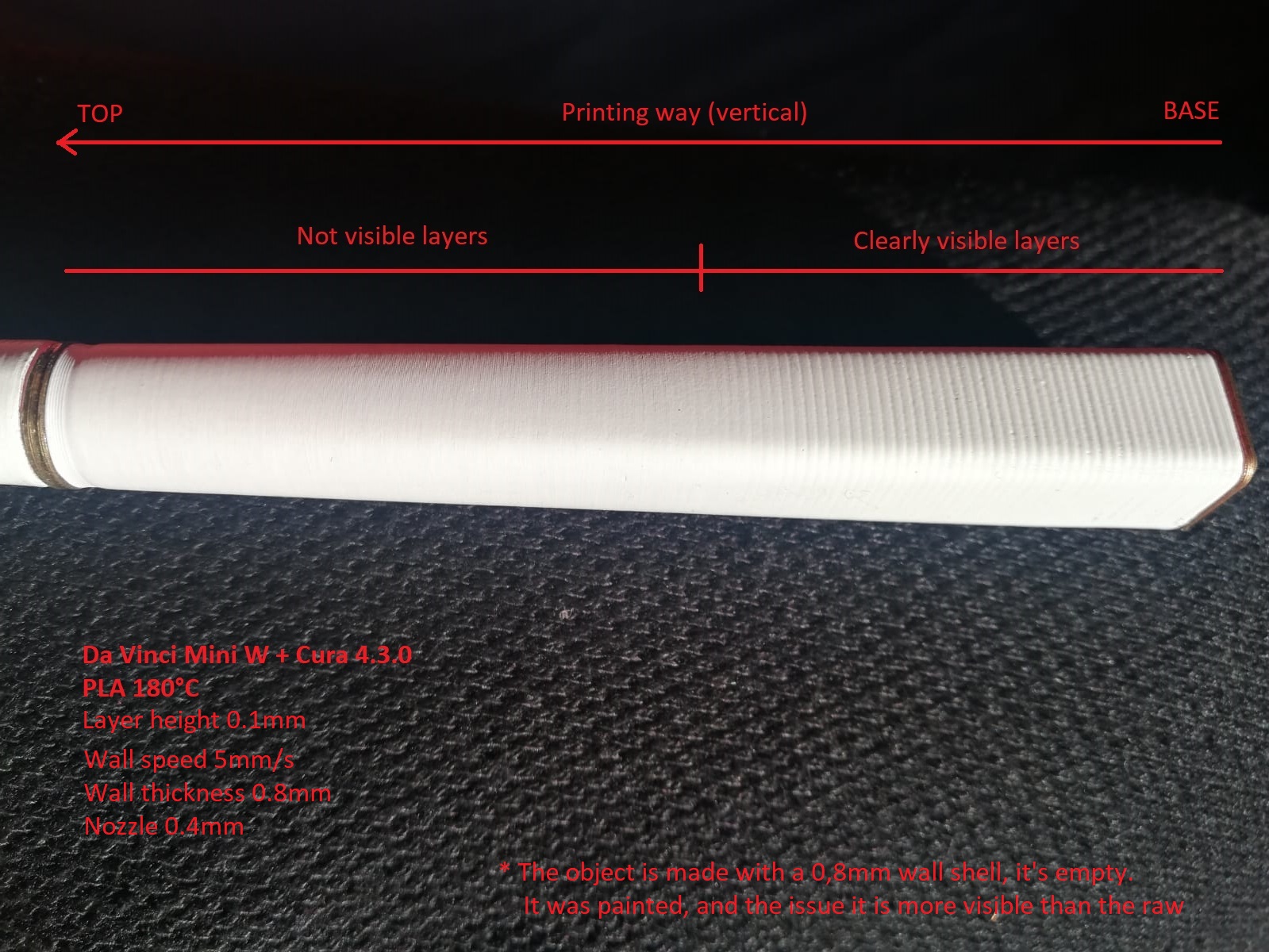

Maurone999 wrote:I'm facing a strange behaviour.

Half of my prints has visible layers, the other half has an almost perfectly smooth surface.

It shows that is possible to have not visible layers, but I can't understand how!

Moreover, I noticed if I raise the temperature layers are more visible If I reduce the temperature surfaces seems smoother, but If I reduce too much the temperature surfaces become much smoother but also surfaces become deformed and bent.

How is it possible?

How can I have 100% of the piece perfectly smooth?

Has someone faced the same?

sorry, but those are not individual layer lines you are seeing.

that is most definitely Z banding, and each one of those "ridges" is made up of multiple layers - especially if you were using a 0.1 layer height.

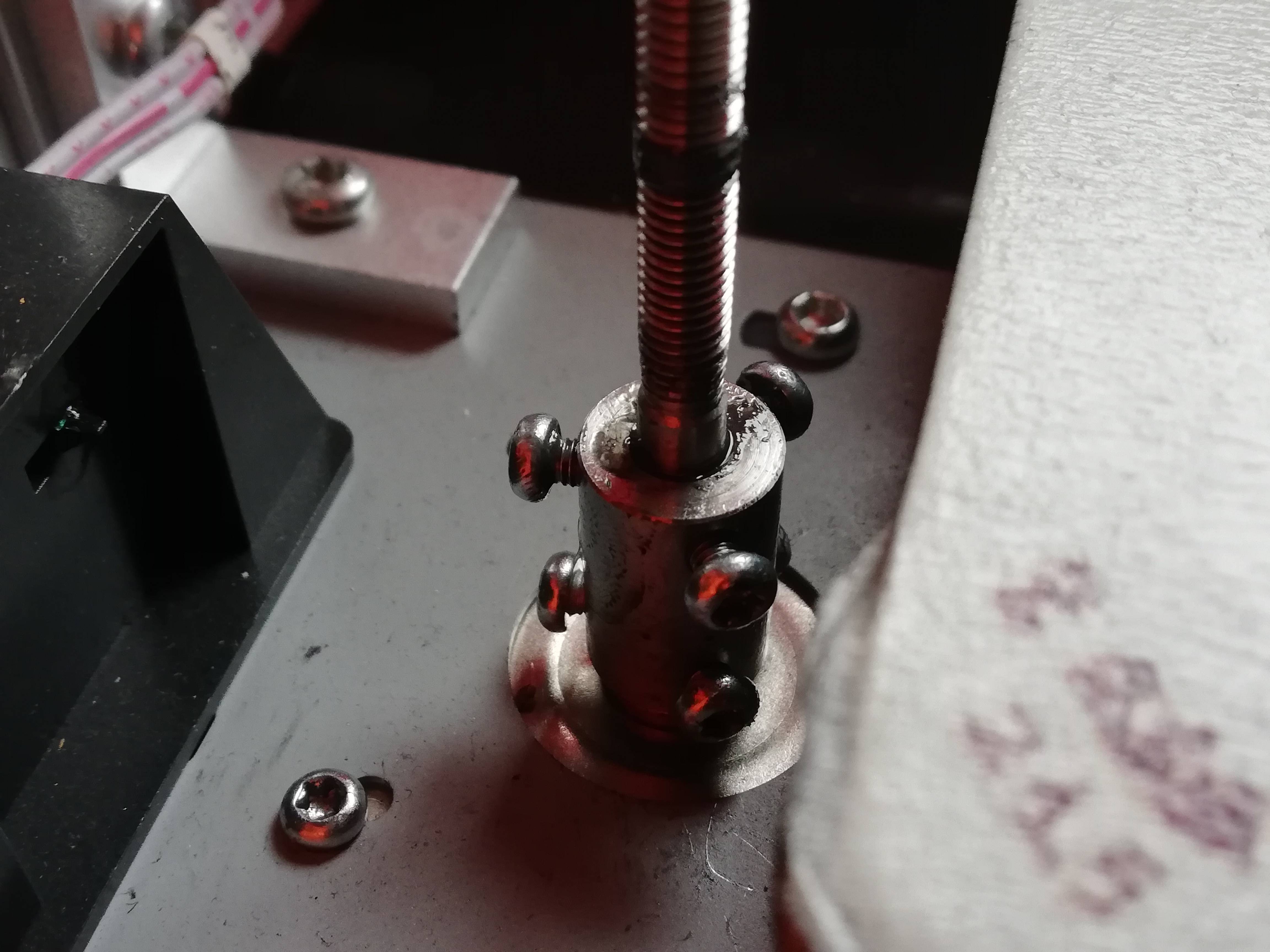

Z banding is definitely a mechanical problem. There is something loose, somewhere, that is allowing movement that should not be there.

For this particular issue, it is quite often the bed that is wobbling around. I would start there.

SD4 #1 & #2 - Lawsy carriages, E3D v6, Rumba controller board, mirror bed plate, X motor fan, upgraded PSU & Mica bed heater

SD4 #3 - in the works ~ Folgertech FT-5, rev 1

Printit Industries Beta Tester - Horizon H1