Topic: PETG Pellets BETA UNTESTED experience

BETA UNTESTED comes in 3 types, i picked XT1800.

The good:

PRICE !

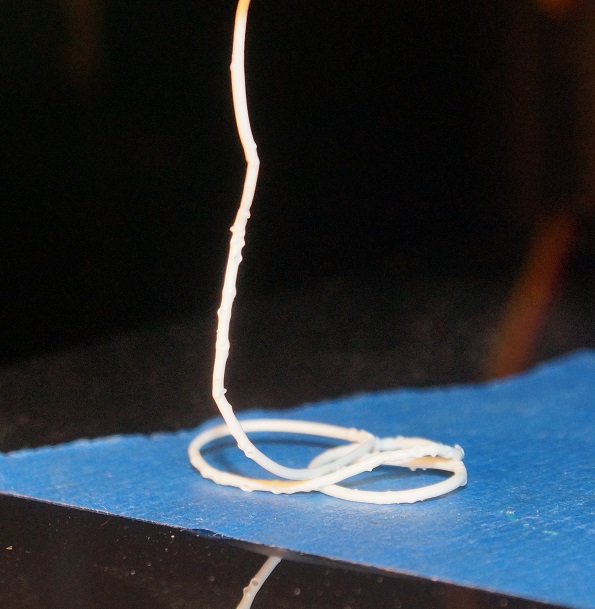

Extrudes very fast and if temp is stable, diameter is also stable.

No cooling needed (ambient temp about 50F garage)

1.8m nozzle results 1.8mm filament. Fine tune diameter with angle of exiting the nozzle is easy.

Unlike Eastar 6763 Clear, TX1800 has NO smell when printing.

The bad:

Cannot pause extrusion process. It has to be continuous or barrel will get jammed and will require disassembly and cleaning.

DO NOT fully insulate the barrel. Only the heater band. This will help to avoid potential jamming cause by soft pellets.

Pellets get sticky but not yet soft so it creates a problem.

Pellets are None stock. You could bi sitting for weeks waiting it to be shipped.

Harder to fine tune filastruder to get this going compared to PLA or ABS extrusions.

Extrusion temp is high. 250C.

Printing temp is even higher. About 300+C needed to print, otherwise layers wont bond very well.

PETG is hard to get to stick to the bed (any PETG) 90C+ on the bed+hair spray or gel solves this problem.

If you start extruding, you better not stop. Any pellets inside far from the nozzle can get soft and will cause a jam.

Clearing out and doing at least 1 layer of barrel insulation solved the problem to a point of being able to extrude.

Hot PETG does not slide over PTFE tube very good. Make sure filament passes through filawinder sensor as centered as possible and does not slide across PTFE tubes. Once cooled, no problem with that. Same for all PETG.

Corners of large prints (50x50 cube) curl up even at 90C bed temp much like ABS does. (see picture below)

Drying temperature is rather high, 4hrs at 220F-230F but am not sure it was even necessary.

Print temperature is very high. 300C and bed at 110C and higher for larger prints

This temperature is likely to damage your nozzle or your printer so try at your own risk.

I used powder colorant mixed in with the pellets and i think this was by far the biggest mistake i've made.

Pellets started to stick and refused to go into filastruder unless i tap the barrel.

After washing off most of the powder, i dried it with hair dryer and resumed extrusion.

To my surprise, it extrudes well even after getting soaked for at least 30 minutes in cold water.

Color turned out to be very even and embedded into the pellets so well that from now on i will always wash pellets in colorant powder and then dry them before extrusion.

First 10mm was printed at 260C. Then i slowed printer down to 20mm/s so it can climb to 270C and printed about 15mm. Then i switch print speed back to 40mm/s and it maintained 270C for the rest of the print.

Layer height 0.3mm (99.9% of all my prints)

PETG seems to like cooling fan. Helps allot with small curling on the sharp edges. I will not post cooling % because my fans dont match yours.

I later managed to push to 280C but it still wasnt enough.

Test model i printed is my own. Each pillar is 10x10 and 20mm gap between the pillars connected with the bridge at the top.

Printed with old CURA 15.

Bridge came out very nice, suggesting smaller parts dont need support as long as there filament can have A and B points to connect to.

Layers did not stick very well due to being unable to run it at higher temps. Pieces come appart without much stress.

I cant say that higher temperatures would fix it because plastic could just become brittle after going through 270C nozzle.

Until then, i cant say 100%

In summary:

I like PETG (in general) but TX1800 is too much.

Because of its high temp demand, problems keep growing as temperatures rising.

Would i recommend TX1800 ?

For 99% of people i'd say no because of excessive temp requirements.

Would i recommend Eastar 6763 Clear instead ?

No. It prints at much lower temperatures but it has strange sour like smell that is very difficult to get rig of.

my 3d models http://www.turbosquid.com/Search/Artists/tonycstech