Topic: questions from a new DLP printer owner

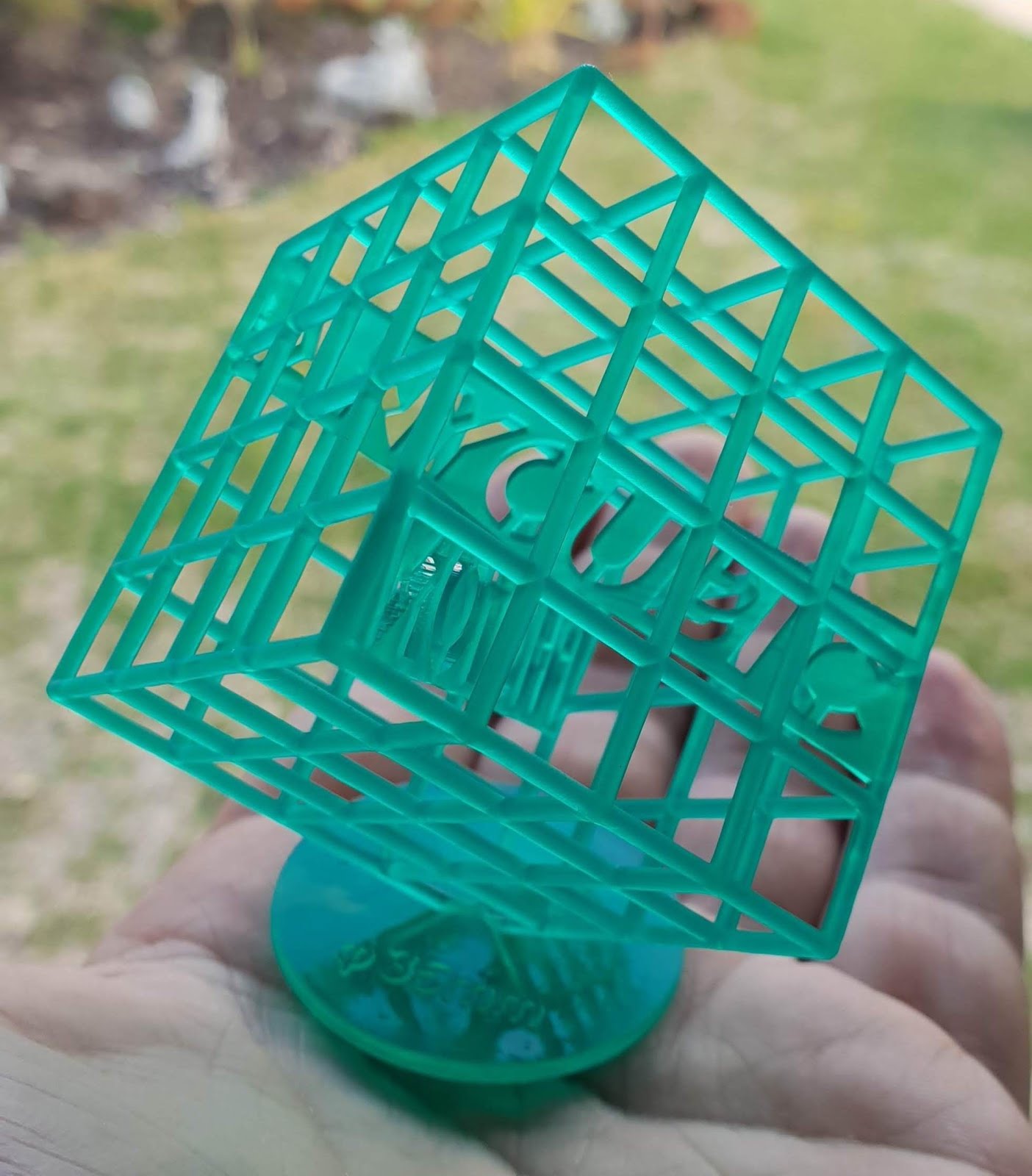

Finally my Anycubic Photon arrived. I've previously owned a Solidoodle 3, 4, an Anet and this is my first DLP/SLA printer.

I got few questions I can't really find answers to in the manual and anywhere online really.

1) I understand the resin is toxic but just how toxic is it? Technically both alcohol and cyanide are toxic but just how much is what really matters. To me the smell is mild and like UV curable epoxy glue, although fills up the air really fast.

What about skin contact?

I understand the manual tells you to use the face mask, safety glasses and and gloves, but I've dealt with the smell and physical contact of 99.6% grade acetone a lot of times, the heavy smell of melting ABS and this stuff doesn't feel nowhere as bad. This is why I wonder.

2) Anyone tried 0.01mm layer printing? The slicer and manual state that as option but can't find anyone using it online or what exposure time to use. I want to experiment with printing and polishing DIY lenses with this ( as seen for example here: https://formlabs.com/blog/3d-printing-t … ear-resin/ ) and this is why I ask. I understand for the rest of 99.9% use cases it will be a waste of time.

3) Is resin left in the tank after a sucessful print discarded or reused? I believe the former but since the manual mentions draining it with a funnel with a filter and storing the leftover resin from the tank in a container but not specifying what container and storing for what I wanted to make sure. Those funnels also seem single use and I'm going to run out of them really soon.

Thanks.