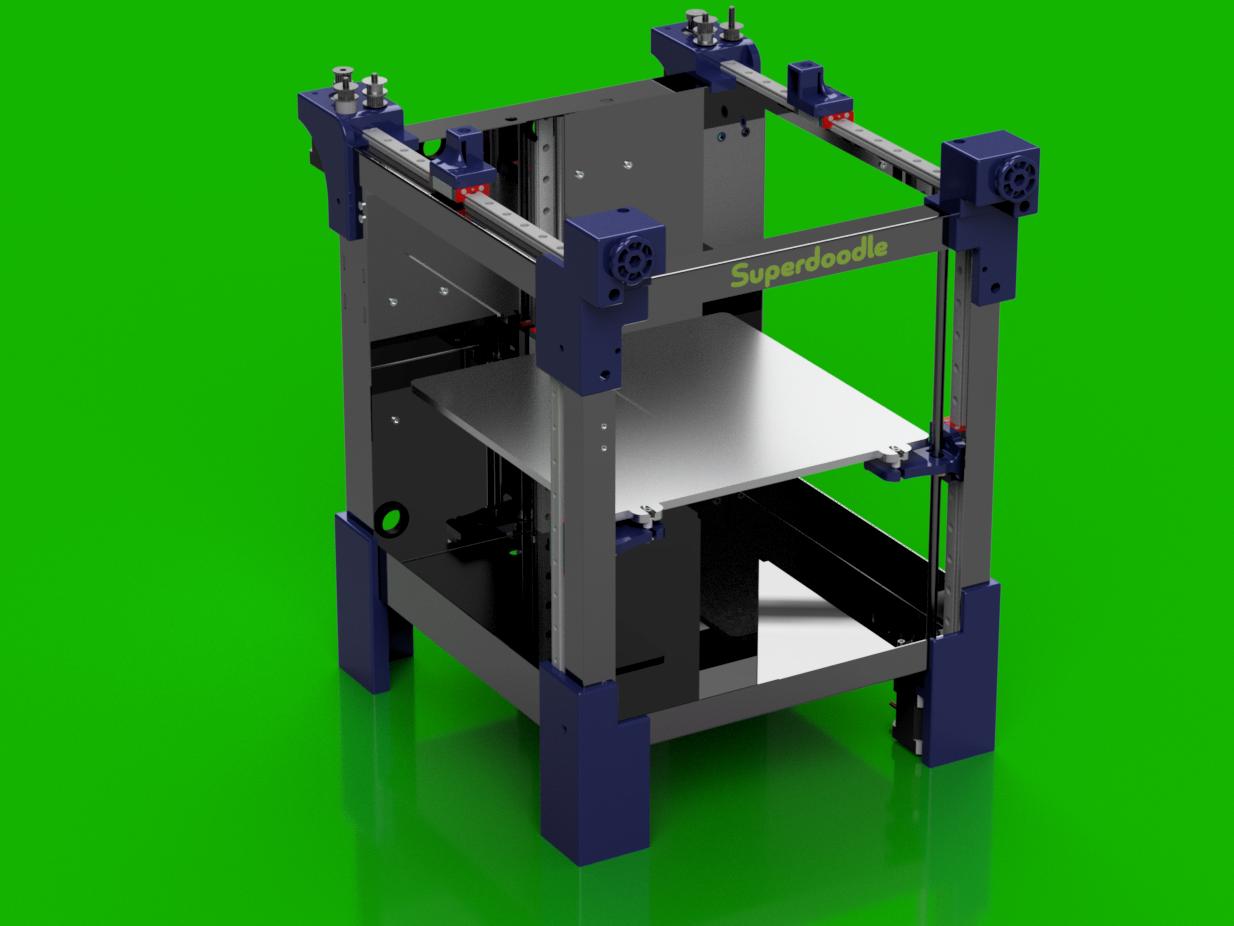

Topic: SuperDoodle - Design Progress

I hate putting stuff up before it's finished but I figured there might be some helpful criticism out there. I have been pinging ideas off the guys in chat but they are going to be well sick of me before this project gets done.

Here is the Fusion 360 Project Link

The goal for this build:

Use the SD3 frame to construct a high performance printer

Create the largest build volume possible inside of the SD3 frame (currently looking like 250x250x300

Try to keep parts around $800 - $1000

All parts should be off the shelf commercially available (some modification to parts okay)

Make sure that the build will be future proofed

In the spirit of the Solidoodle, make it easily moddable

Include the following features:

Capable of printing to temps of 400C

Bed capable of 150C

Auto bed leveling (or mesh bed leveling)

Multi-extruder capable

200 mm + print speeds

.25mm layer heights

Hotends should be quick swappable (think ultimaker)

My progress to date: (2019-03-03)

Reverse-engineered SD3 sheet metal frame and cutouts

Basic layout of Z Axis and feet

Most motion parts selected

Bed mounts created

Feet finished

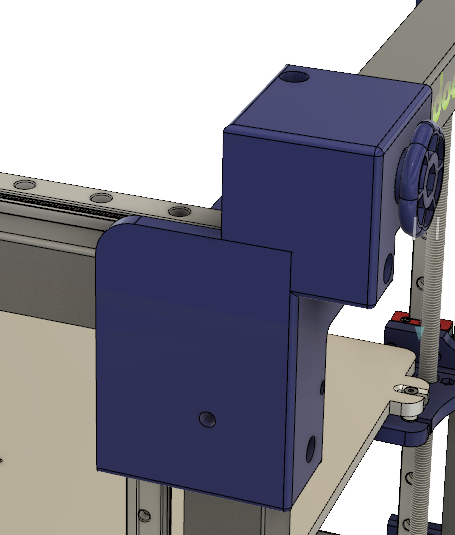

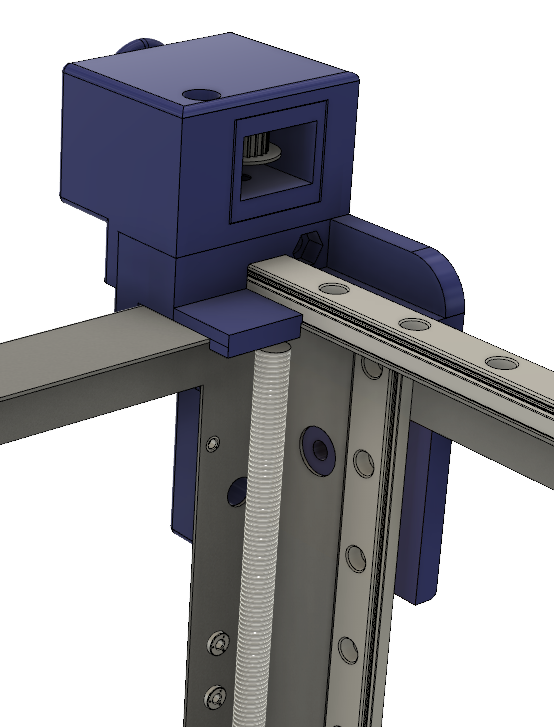

Core XY motor mounts created

Added first revision of tensioner pulleys

To Do: (r/restofthefuckingowl)

Mount MGN12 rail for Z -Axis (need to decide on size first, see issues below)*

Add mounting points for future HDPE Side, front and bottom panels

Create mounts for bowden steppers

Make XY carriage assembly

Make mount for hotend(s), probe and fans

Design hotend interface PCB(maybe Rev.2)

Make final BOM and source parts

I have a couple issues that I am looking to solve.

First, the bed I want to use is really close on space so I had to remove a small piece of the mount in the rear. I think that is going to translate into my having to get the grinder out to finish it.

Second, along those same lines, is the mgn12 z axis rails. They are 330 mm long but I can't find those. The max length that will fit is 347mm for the SD3. The closest I found is 350 mm. I have access to a mill so that might not be impossible to shave 3-4 mm off. Might use the grinder again?

Lastly, for now, tolerances are too tight everywhere. Need to generally relax the tolerances to make up for the metric and imperial conversions that they used on the frame. Seems like everything is off just enough that everything is just past snug

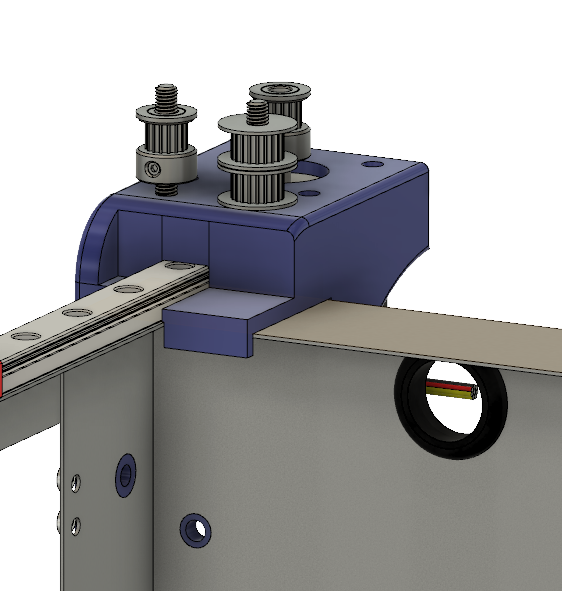

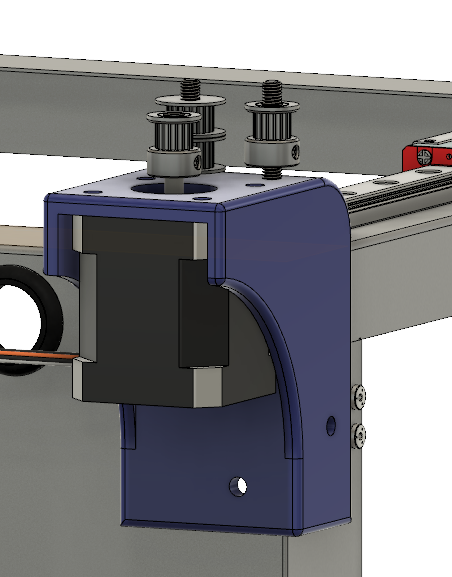

Update: 2019/02/24

I think that I managed a decent pair of motor mounts without drilling more holes. Test fitting may change my thoughts on that. Here are some screen grabs. I updated the link to the latest version for anyone that wants to download the files.

Update: 2019/03/03

Slow progress this weekend. Added a set of from pulley tensioners. Ends up being a 3 part system. Not really happy with the solution but it's a starting point. Current issue is the XY carriages. I am having trouble figuring out how to affix the mgn rail. I think this might have to go to 10 mm rod instead.

Per usual, I have updated the fusion 360 link and added a couple progress pics below.

Glass bed with QU-BD heat pad upgrade, threadless ballscrew w/ 8mm smooth rod, spectra line belt replacement, lawsy MK5 extruder, Lawsy replacement carriage, E3D hotend, Ramps 1.4 w/ reprap discount controller, DRV8825 drivers, 12v 30A PS, Acrylic case, Overkill Y-idlers, Filament alarm, Extruder fan + more.