Topic: How to identify a temperature sensor on a solidoodle

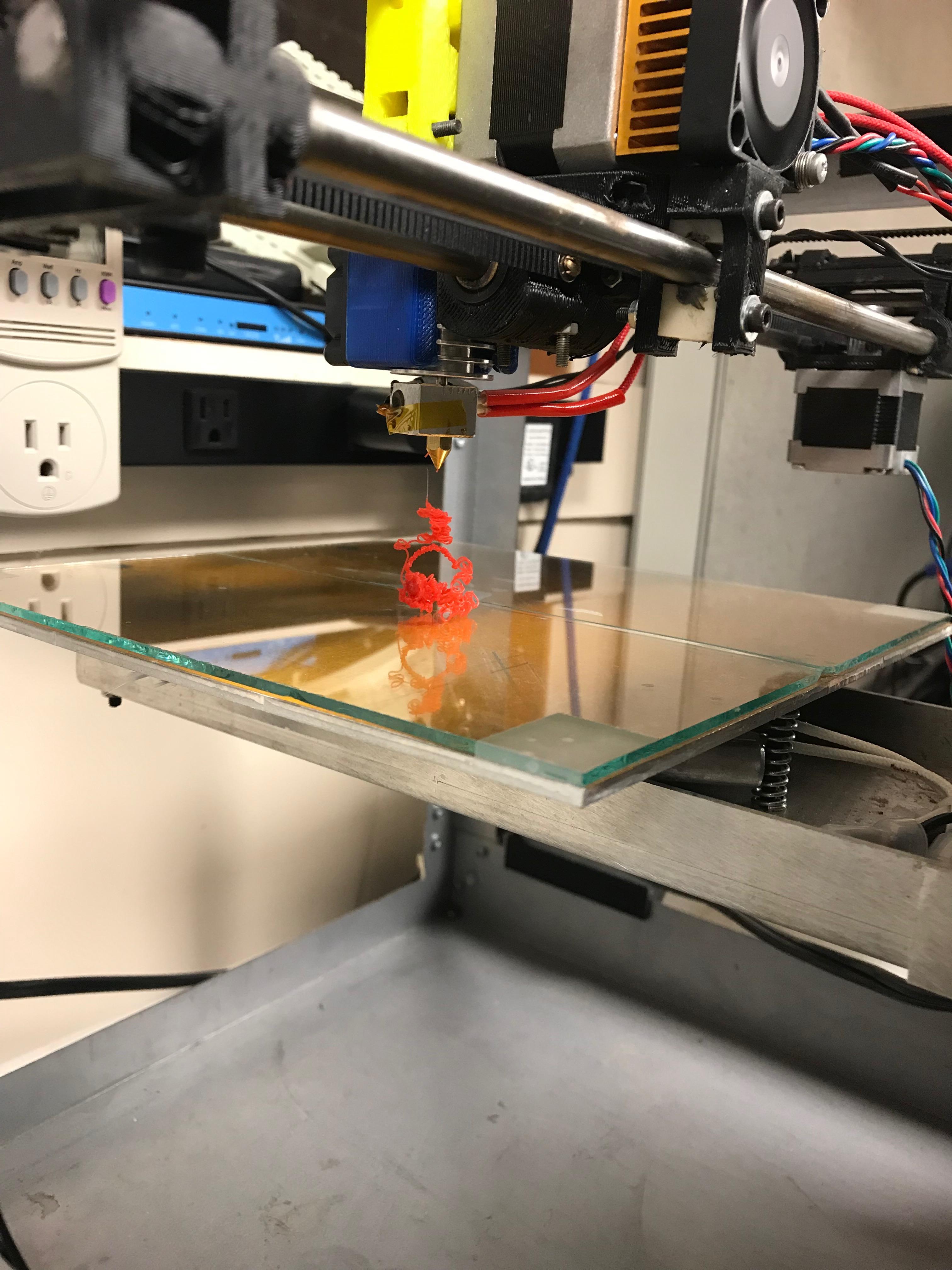

Recently i found a 3D printer lying around in our company warehouse.

I got it and found that the main board was bad so i bought the Ramps 1.4 kit and installed it. The X,Y and Z axis motor run good manually. I have also set them up with their single side limit switches.

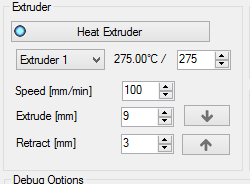

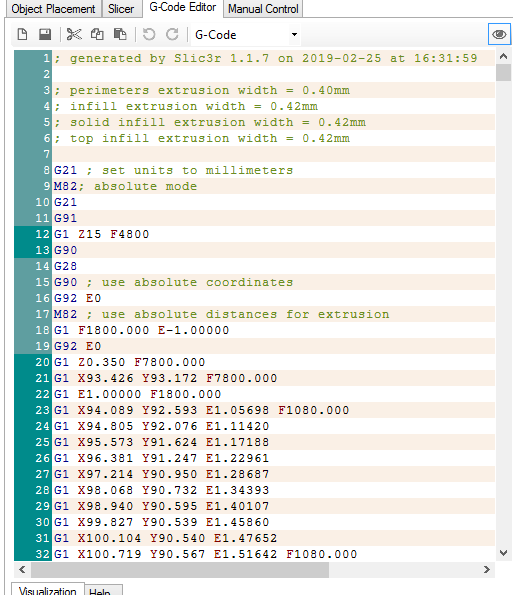

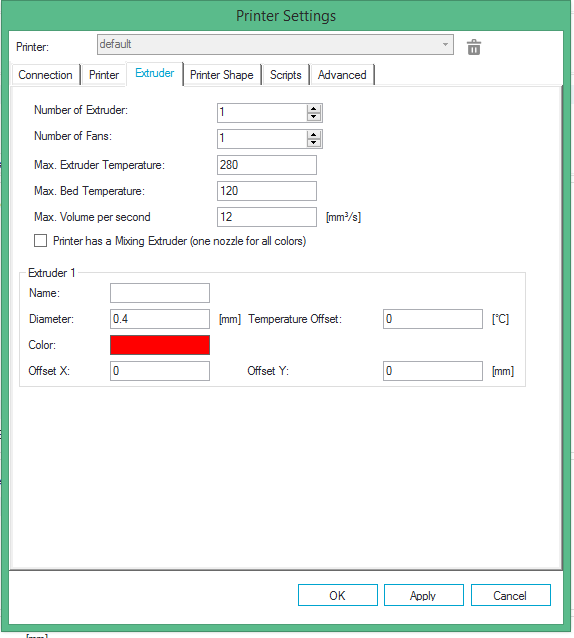

Problem 1: Now since this morning i have been trying to run the extruder motor and set a temperature on it. I am using the Marlin firmware. I didnt do much changes on the configuration program until i found that i have to set a temperature sensor in the program. But this being a very old unit, i dont know what temperature sensor is in there? i tried number 8 and 5 in the configuration but no success.

Problem 2: the extruder motor wont rotate. it makes this loud noise, but dont see it rotating. I also tried altering the stepper driver potentiometer up and down but nothing changed. Not sure why isnt it rotating, maybe because it is trying to push to feed in but because of the material meting shut the gateway, dont know.

Any help will be appreciated.

Thank you.