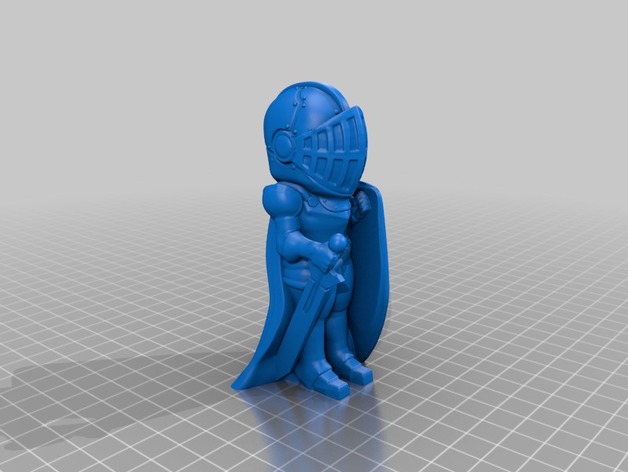

Topic: Sir Layersalot

I downloaded this file to print :

https://www.thingiverse.com/thing:3178033

It is reported as an easy print and since my Ultimate Maker does a good job no problem right ?

The first print on my original extruder. and a different roll of filament came out nice except a bit of trouble with the overhang on the sword. near the bottom I tried turning the model 90 degrees and i got stringing and the back edge of the shield looked horrible.

This did correct the messy overhand on the sword. but a different anomaly happened. same settings just turned 90 about the z axis.

After several aborted attempts I think i may have a good one on the printer except it is taking a bit long to print. so still need to tweak. This is a large stl at over 18kb and slic3r struggled to slice it cura was much faster.

I ultimately got it to slice with slic3r by slowing down the small perimeters.

I think i got this but suggestions welcome . and has anyone else had a similar experience where 90% of a print comes out great but there is that one area that will not print correctly ?

FT5 with titan/ E3D Aero------MP mini select w glass bed

MP Utimate maker pro-W bondtech extruder

Marlin/Repetier Host/ Slic3r and Cura